Adaptive temperature and stress control method of large-volume concrete

A large-volume concrete and stress control technology, which is applied in the direction of non-electric variable control, control/regulation system, and simultaneous control of multiple variables, etc., to improve iteration efficiency, improve efficiency, and solve the effect of varying structural types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

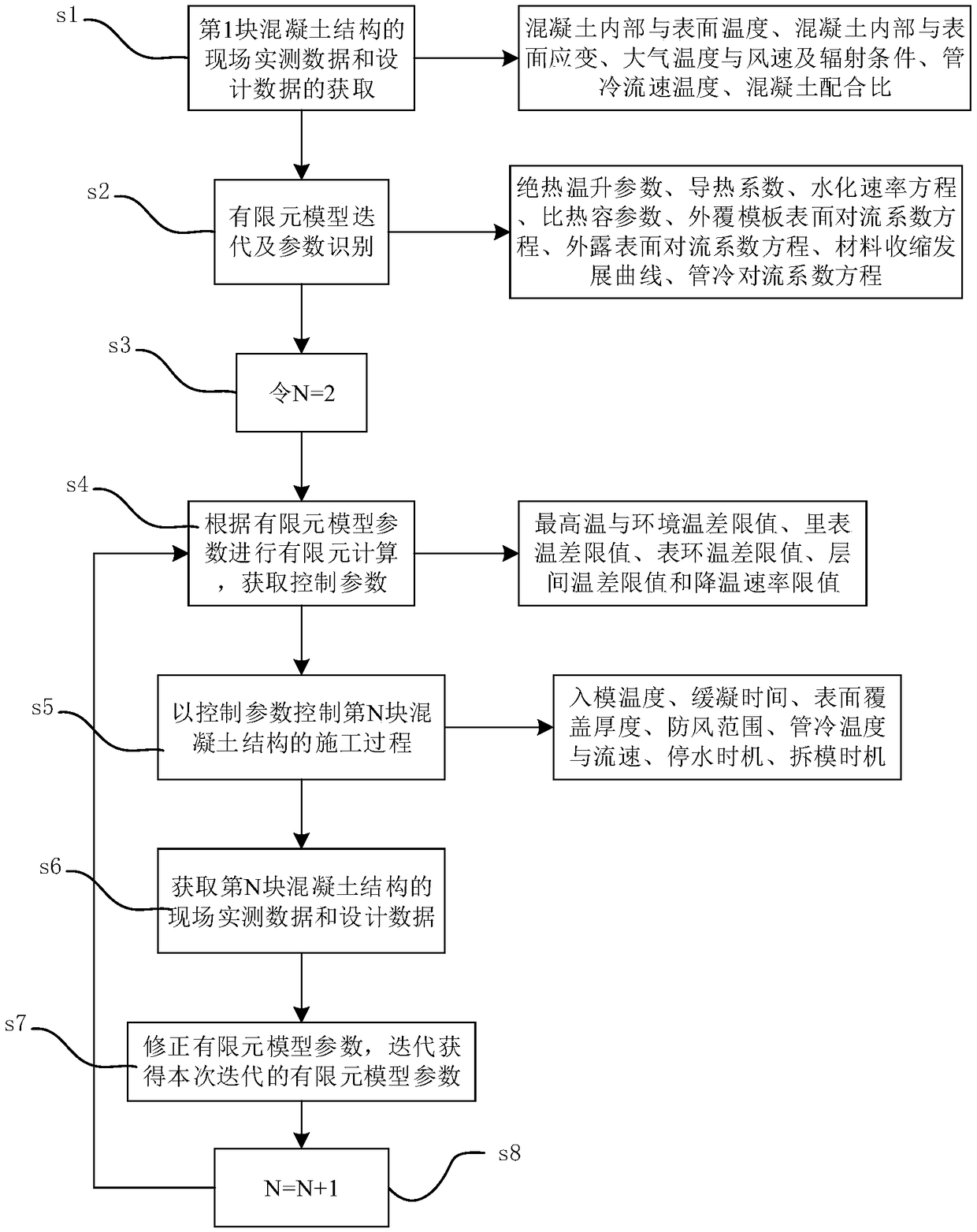

[0029] Such as figure 1 As shown, this embodiment provides a mass concrete adaptive temperature and stress control method, which is suitable for multiple identical sub-concrete structures of the same mass concrete that have been constructed successively or multiple identical mass concrete structures that have been constructed successively structure control, including the following steps:

[0030] Step s1, before constructing the first concrete structure, iterate and calculate the finite element model with the standard value or engineering experience value as the initial condition of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com