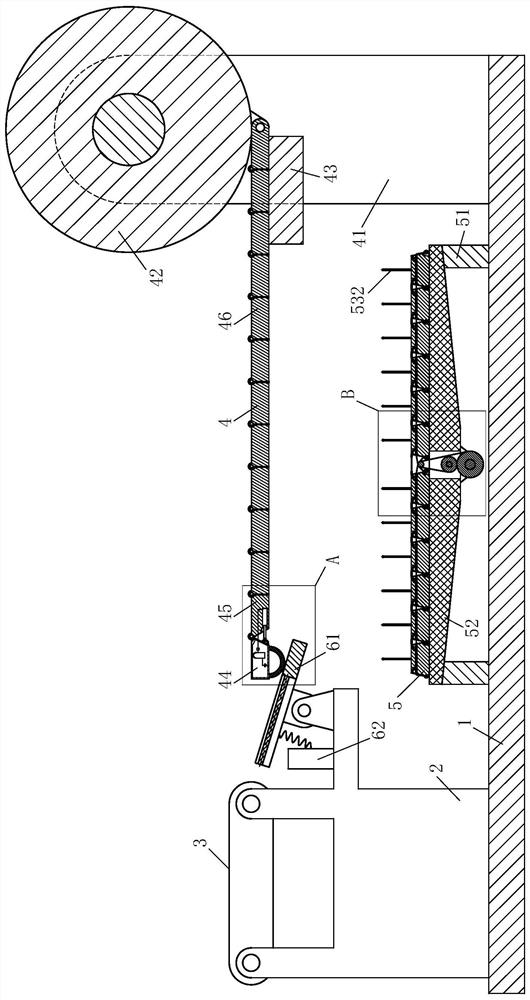

A crop straw baler

A crop straw and baler technology, which is applied in the field of agricultural machinery, can solve the problems of low production efficiency, high cost, and non-uniform shape of straw, and achieve the effects of convenient transportation and storage, improved work efficiency, and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

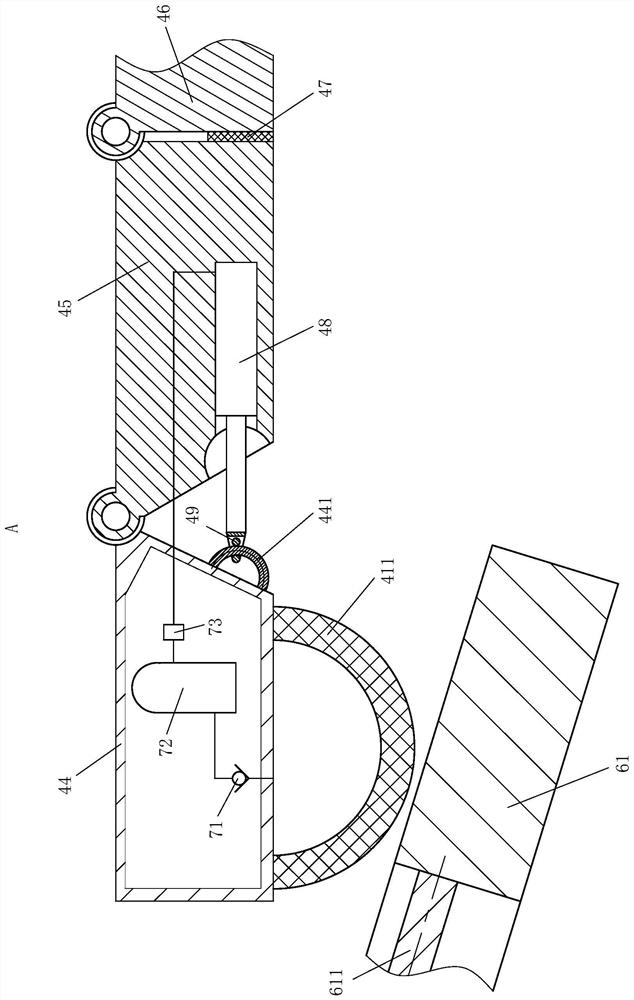

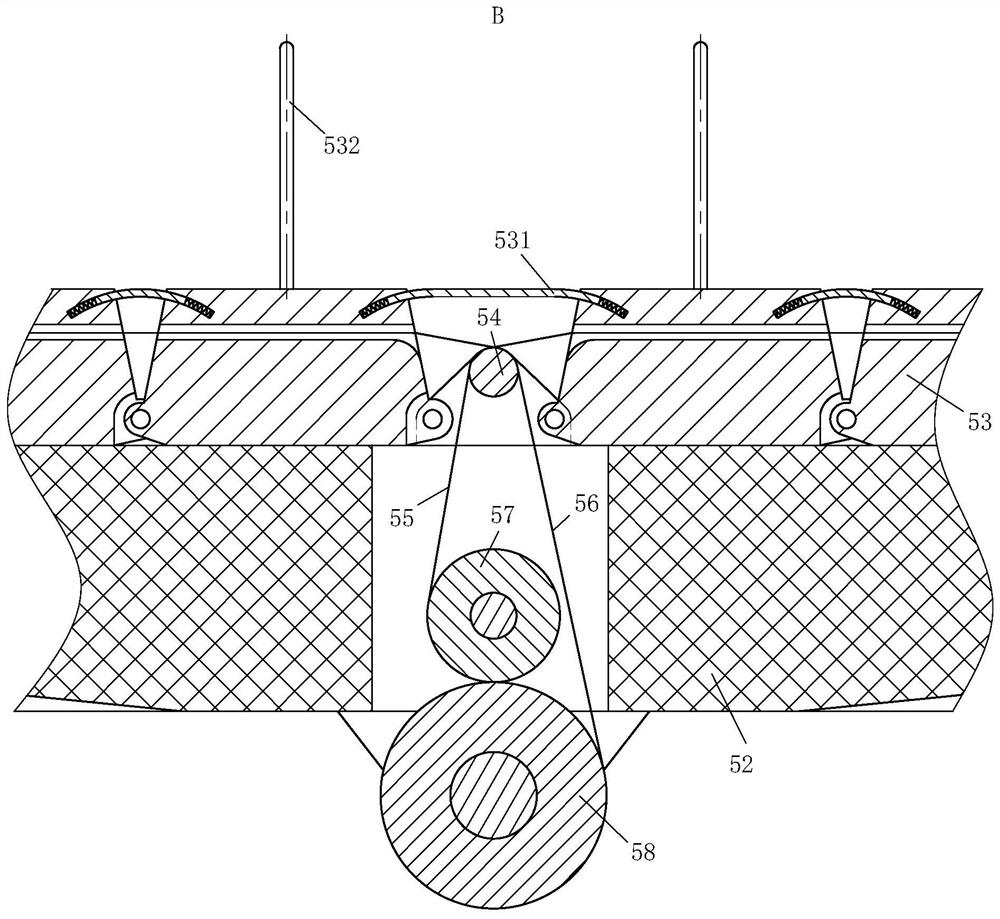

[0026] As an embodiment of the present invention, a swing bracket 61 is provided under the left side of the No. 1 bearing plate 44; A limit block 62 is provided below; the left end of the swing bracket 61 is connected to the limit block 62 by a spring; the limit block 62 is fixedly connected to the cantilever beam of the support frame 2; a semicircle is set below the No. 1 bearing plate 44 shaped airbag 411; the left end of the swing bracket 61 is provided with a rectangular through slot, and a group of support rods 611 are evenly distributed in the rectangular slot of the swing bracket 61; the right end of the support rod 611 is fixedly connected to the rectangular through slot of the swing bracket 61 When working, the belt 3 transports the straw to the support rod 611 on the swing bracket 61 for waiting, when the No. 3 bearing plate 46 slides off the cylindrical surface of the roller 42 under the action of its own gravity The No. 1 load-bearing plate 44 hits the upper end su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com