Prefabricated roof greening plant support

A roof greening and prefabricated technology, applied in the fields of application, cultivation, agriculture, etc., can solve the problems that the vegetation layer cannot be directly applied, and achieve the effects of improving plant diversity and wind resistance, improving efficiency, and speeding up construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

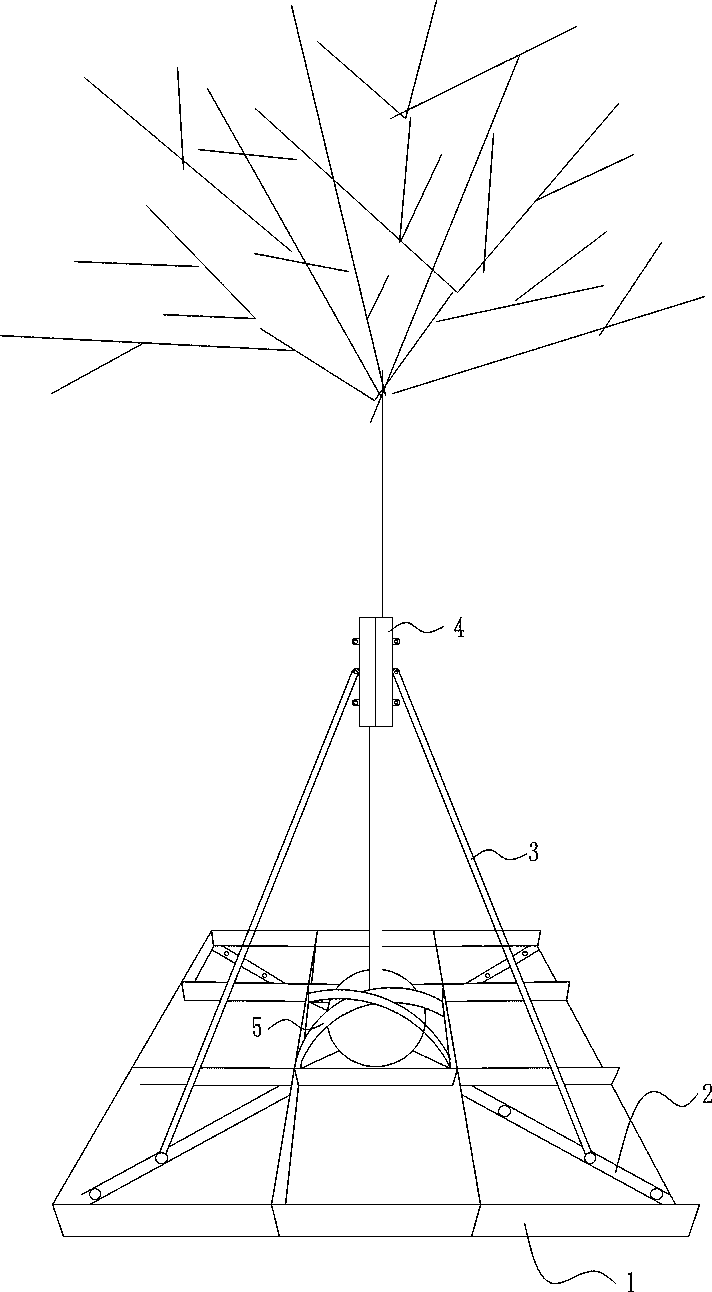

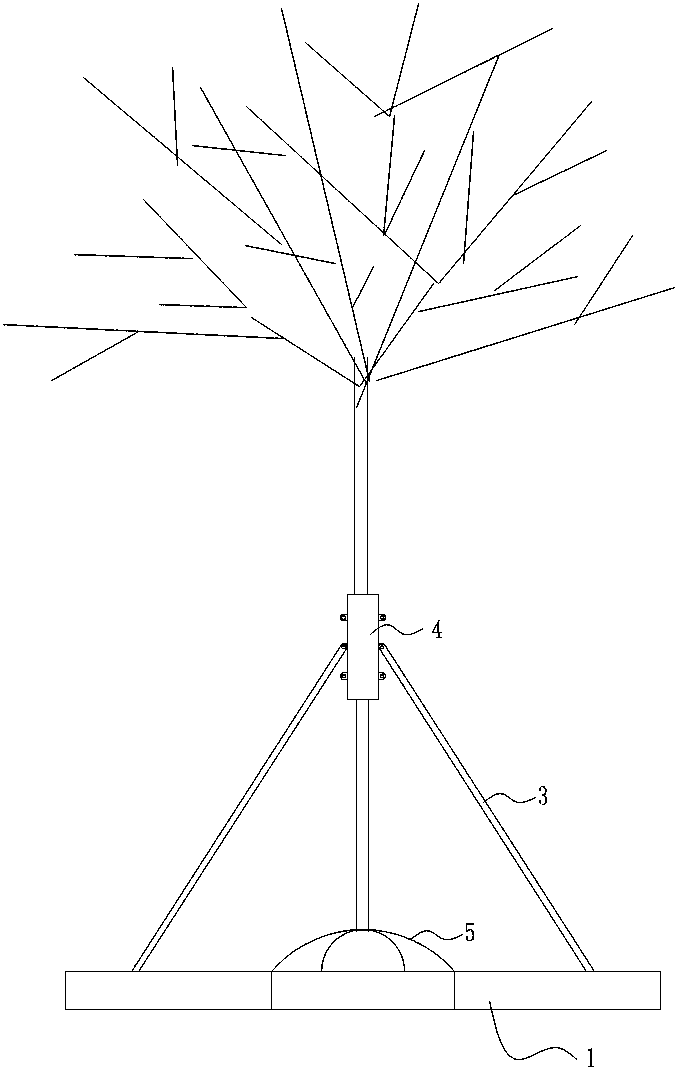

[0029] The prefabricated roof greening plant support of this embodiment is as follows: figure 1 As shown, the woody plant planting unit is formed by combining the modular planting box 1, and the supporting feet 2 and the soil ball fixing parts 5 in the box are installed in the modular planting box 1, and the two ends of the supporting rod 3 are respectively connected to the supporting feet in the box 2 and the vertical connector 5 respectively fix the root and the middle part of the woody plants to meet the conditions for use of green roofs.

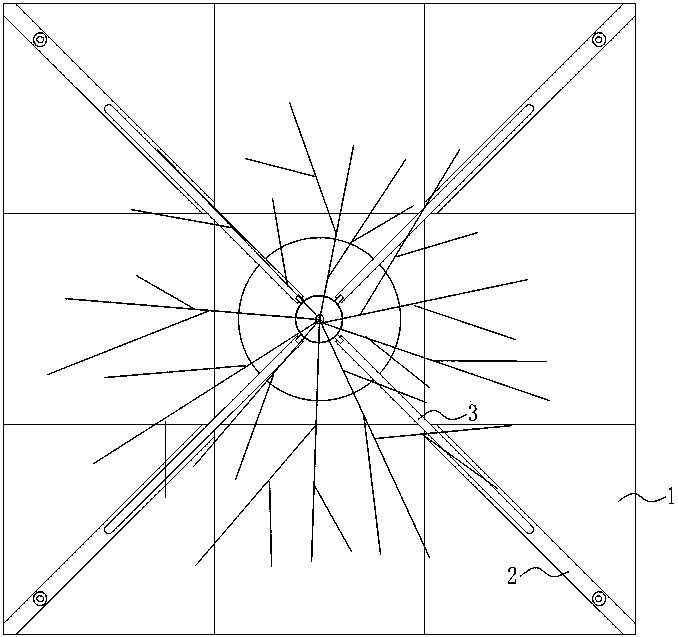

[0030] Such as figure 2 and image 3 As shown, the planting unit of woody plants is a nine-square grid structure composed of 9 square modular planting boxes 1, and the planting box in the center uses cross-shaped soil ball fixing parts 5 to increase the contact surface between the roots of woody plants and the planting box. The support legs 2 in the box are installed in the four corners of the planting box along the diagonal of the un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com