Silica gel chromatography filler and preparation method thereof

A silica gel chromatography, silica gel technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of poor retention of polar compounds, unstable peak area, poor separation selectivity, etc., to achieve increased polar range and good stability , the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

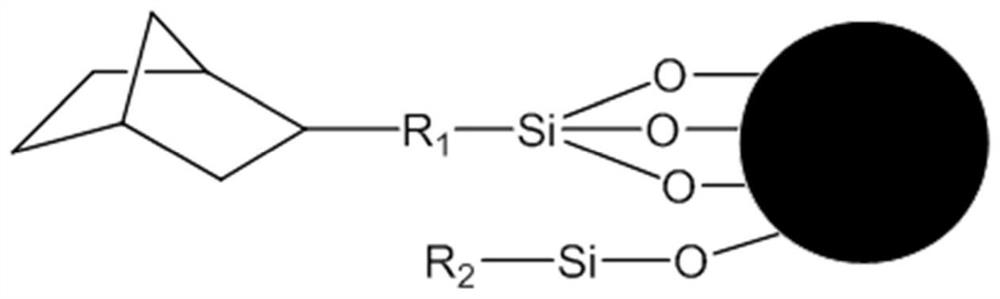

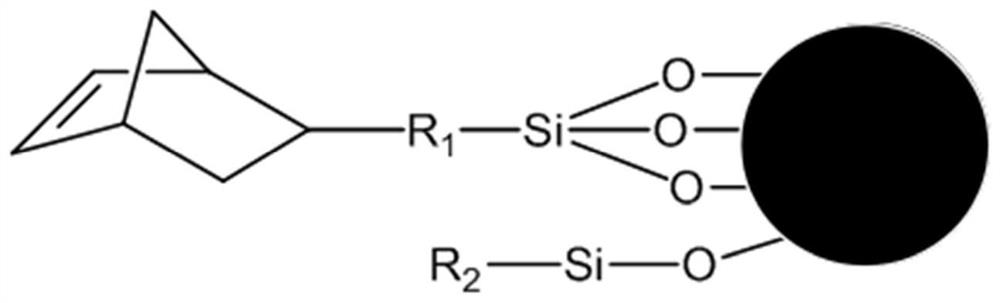

[0042] The present invention also provides the preparation method of above-mentioned silica gel chromatographic filler, comprises the steps:

[0043] S1: Activate and pretreat the silica gel to obtain activated silica gel with silanol groups on the surface;

[0044] S2: Perform hydration treatment, that is, place the activated silica gel in water and stir to obtain hydrated silica gel; the water is preferably ultrapure water.

[0045] S3: Mix the hydrated silica gel, stereosilane coupling agent and other silane coupling agents in an organic solvent, and carry out stirring and reflux reaction to obtain the silica gel chromatography filler.

[0046] Specifically, the silica gel is preferably fully porous spherical silica gel, more preferably ultra-high purity fully porous spherical silica gel for chromatography. The particle size of the raw silica gel used for activation is preferably 3-10 μm, and the pore size is preferably The specific surface area is preferably 180-400m 2...

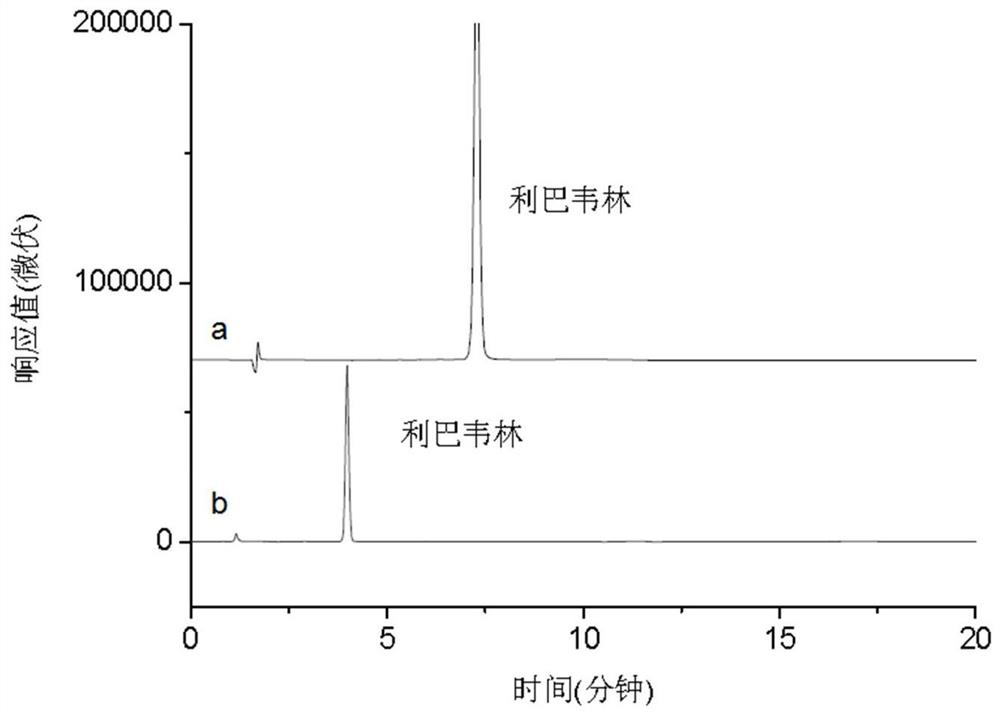

Embodiment 1

[0055] (1) Add 100 g of silica gel (5 μm, purchased from DAISO, Japan) into a 2 L glass reaction vessel, add 1000 mL of distilled water, stir for 30 minutes, filter, and repeat this step twice. Then add 1000mL of hydrofluoric acid aqueous solution with a mass ratio of 0.08%, stir for 24 hours, wash with distilled water until neutral, finally add 1000mL of acetone to wash, filter, and dry at 110°C for 12 hours to obtain activated silica gel;

[0056] (2) Weigh 100 g (5 μm, Specific surface area: 300m 2 / g), placed in a 2L glass material reaction vessel; 5g of ultrapure water was added to the reaction vessel, and stirred at 170 rpm for more than 30 minutes to obtain hydrated silica gel;

[0057] (3) Add the hydrated silica gel prepared in step (2) to the glass material reaction vessel, and add 800mL of dry anhydrous toluene solvent, stir at 170 rpm and add 44.08g bicyclo[2.2.1]hexyl - A mixture of two silane reagents, ethyltrichlorosilane and 6.87g chloromethyldimethylchloros...

Embodiment 2

[0060] (1) Add 100 g of silica gel (5 μm, purchased from DAISO, Japan) into a 2 L glass reaction vessel, add 1000 mL of distilled water, stir for 30 minutes, filter, and repeat this step twice. Then add 900mL of hydrofluoric acid aqueous solution with a mass ratio of 0.06%, stir for 24 hours, wash with distilled water until neutral, finally add 1000mL of acetone to wash, filter, and dry at 110°C for 12 hours to obtain activated silica gel;

[0061] (2) Weigh 100g of activated silica gel (5μm, Specific surface area: 300m 2 / g), placed in a 2L reaction vessel; 8g of ultrapure water was added to the glass reaction vessel, and stirred at 250 rpm for 30 minutes to obtain hydrated silica gel;

[0062] (3) Add the hydrated silica gel prepared in step (2) to the glass material reaction vessel, and add 800mL of dry anhydrous toluene solvent, stir at 170 rpm and add 44.08g bicyclo[2.2.1]hexyl - A mixture of two silane reagents, ethyltrichlorosilane and 8.52g chloroethylmethyldichloros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com