Preparation method and application of defective carbon nanotubes

A technology of carbon nanotubes and defect states, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve problems such as weak catalytic ability and inability to fully utilize active sites of carbon nanotubes , to achieve the effect of excellent performance and excellent oxidation degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

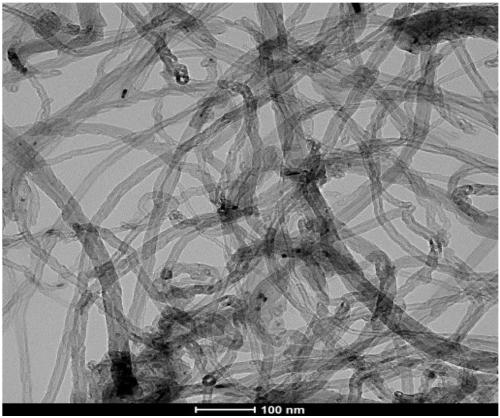

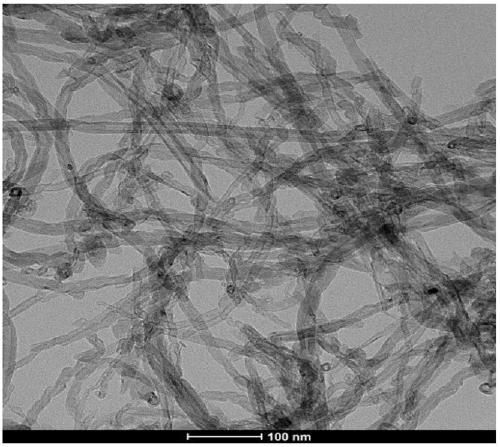

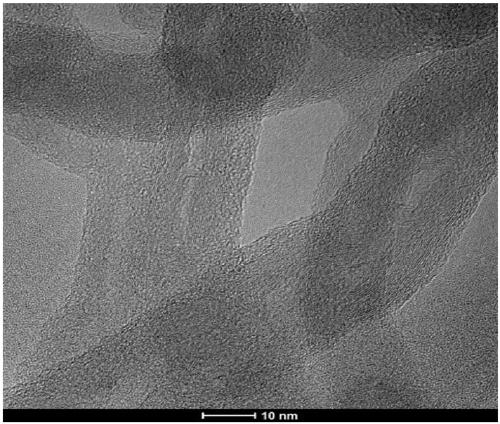

[0019] Specific embodiment 1: This embodiment is a method for preparing carbon nanotubes with defects, specifically according to the following steps:

[0020] 1. Preparation of oxidized carbon nanotubes: Mix concentrated sulfuric acid and concentrated nitric acid evenly to obtain a mixed acid; add carbon nanotubes to the mixed acid, place in a constant temperature water bath, and react for 3 hours at 75°C to 80°C 9h, then repeatedly washed with deionized water and absolute ethanol until the washing solution is neutral, and finally dried at a temperature of 60°C to 65°C to obtain carbon dioxide nanotubes; the concentrated sulfuric acid and concentrated nitric acid The volume ratio is 3:1; the mass ratio of the volume of the mixed acid to the carbon nanotube is 1L: (15g~17g);

[0021] 2. Heat treatment: put the carbon dioxide nanotubes prepared in step 1 in a tube furnace, pass inert gas at a flow rate of 150mL / min to 160mL / min for 20 minutes to exhaust the air, and then heat it...

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment differs from Embodiment 1 in that: the mass percentage of the concentrated sulfuric acid described in step 1 is 95% to 98%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0023] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that the mass percentage of the concentrated nitric acid described in step 1 is 65%-68%. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com