Flotation machine

A flotation machine and flotation chamber technology, which is applied in the field of flotation machines, can solve the problems of poor flotation effect and difficult to fully mix ore pulp, etc., and achieve the effects of good mixing, rich design and increasing eddy current area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

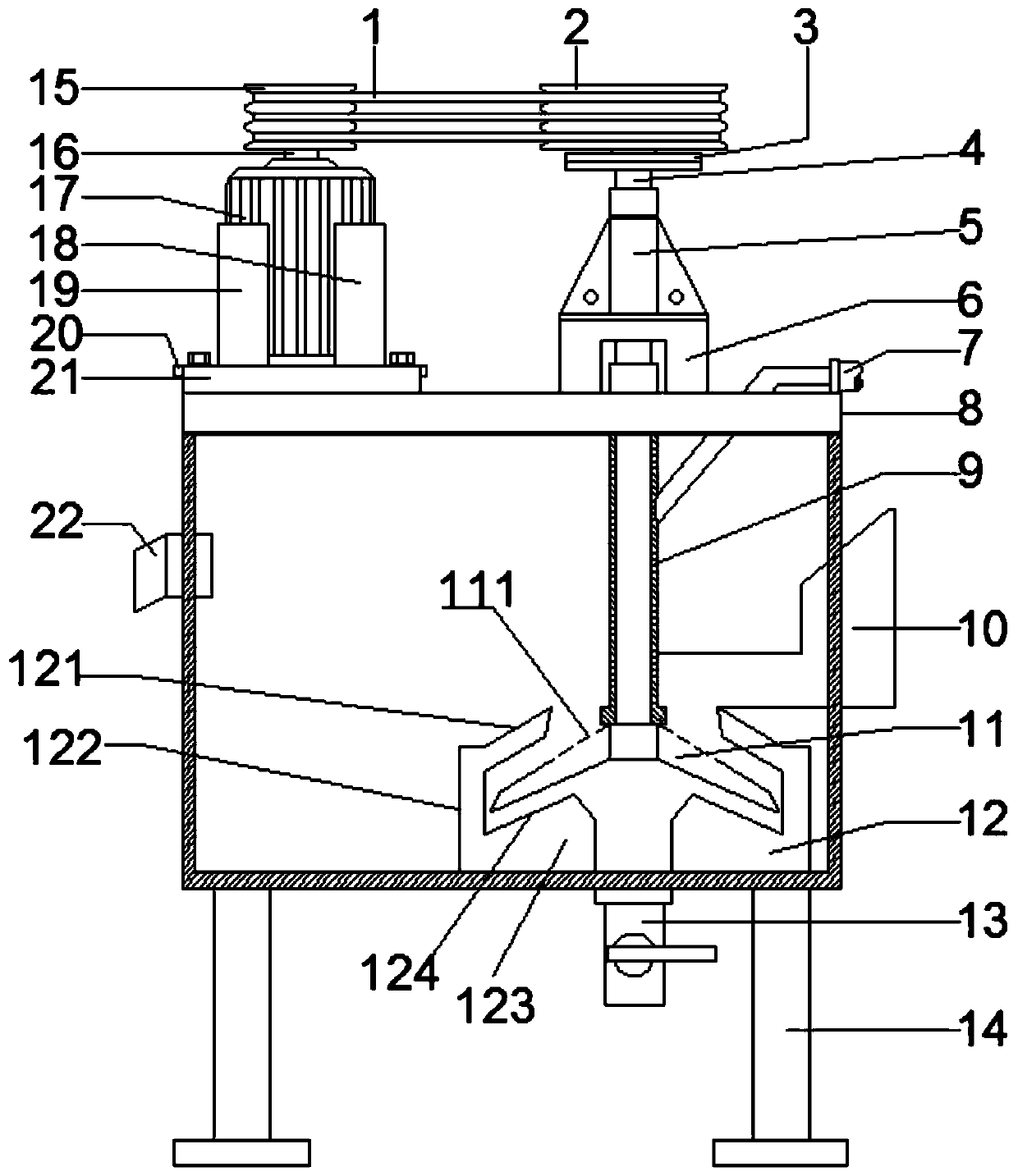

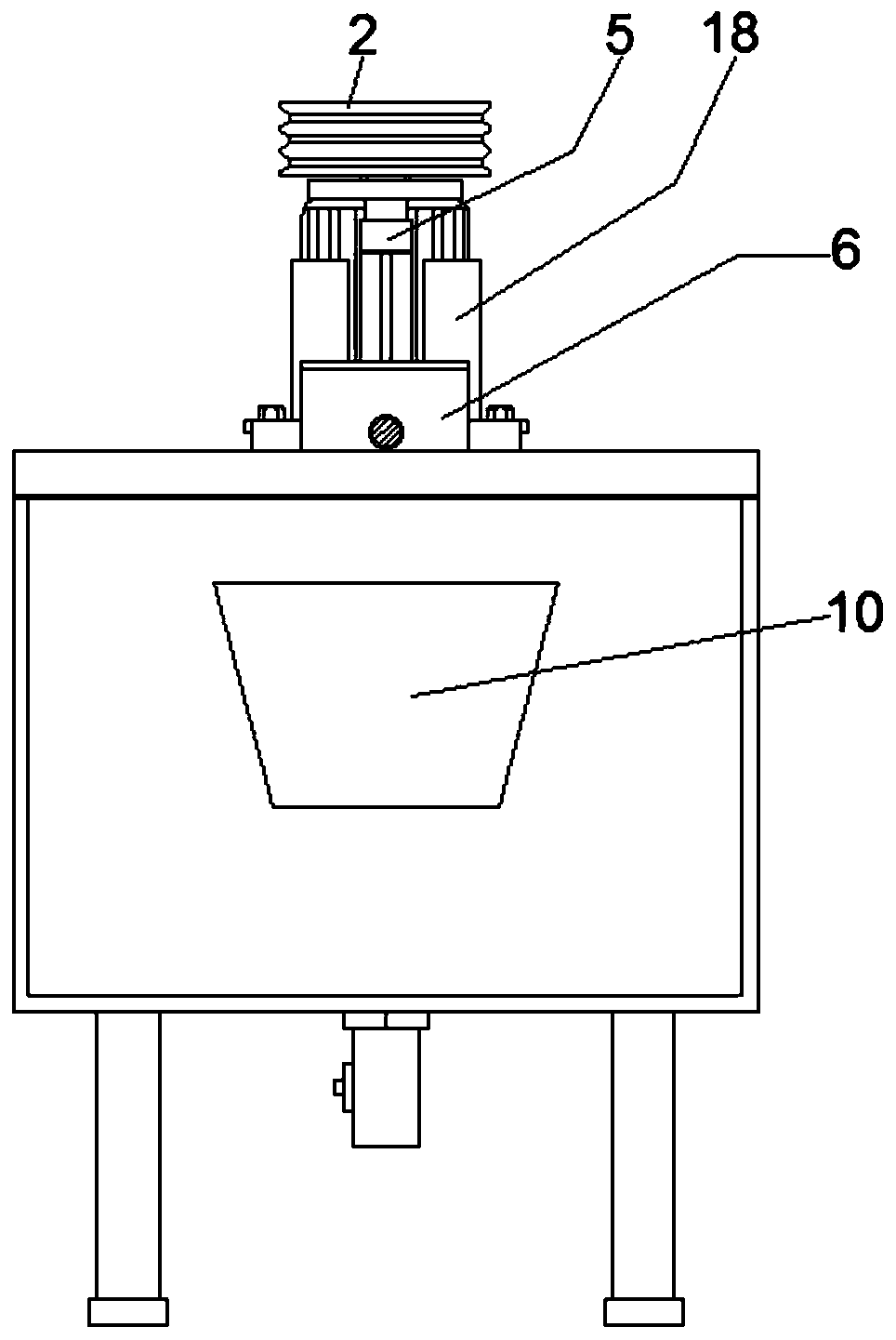

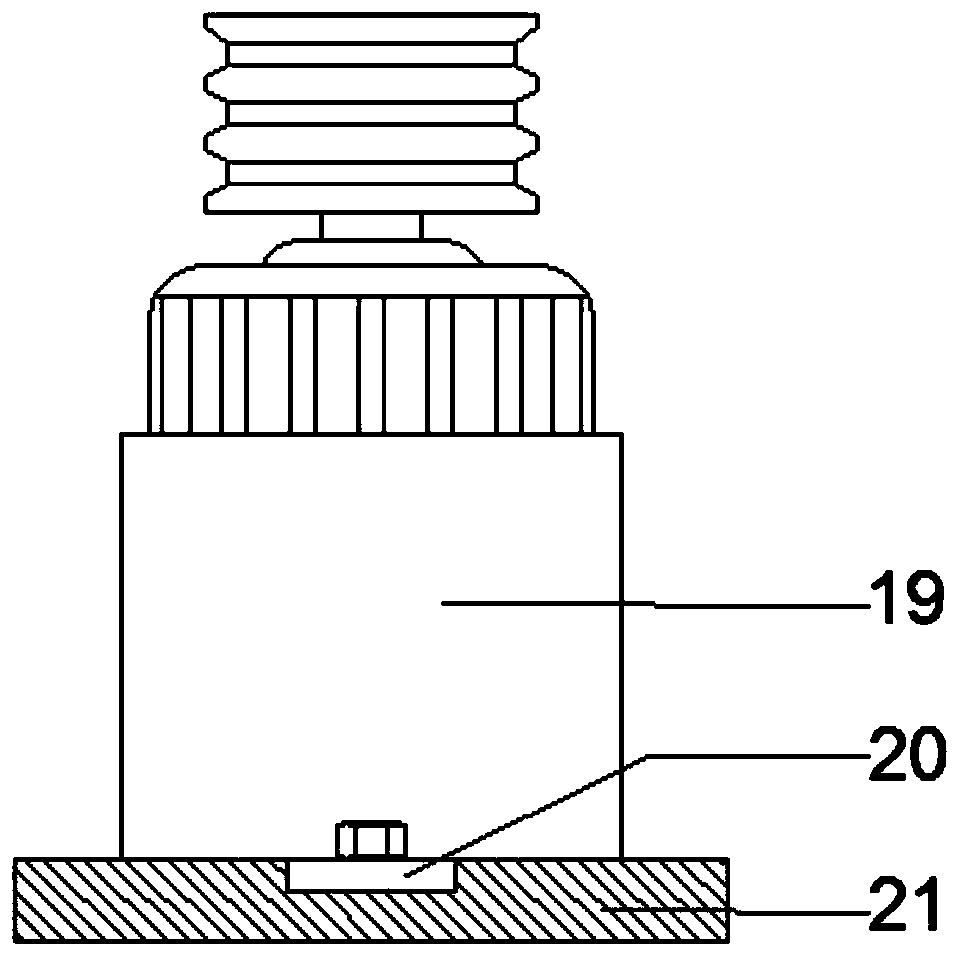

[0021] figure 1 Show the structural representation of the flotation machine of the embodiment of the present invention, figure 2 A side view of a flotation machine according to an embodiment of the invention is shown. Such as Figure 1-2 As shown, the flotation machine provided by the embodiment of the present invention includes: a driving part, a stirring part and a device body 8 .

[0022] The device body 8 is hollow. The stirring part includes a rotating shaft 4 and a stirring cover 11 , the rotating shaft 4 is installed on the device body 8 , and the rotating shaft 4 is fixedly connected to the first end of the stirring cover 11 .

[0023] In this embodiment, the rotating shaft 4 is detachably connected to the stirring cover 11 to facilitate maintenance and replacement.

[0024] The outer diameter of the first end of the stirring mantle 11 is smaller than the outer diameter of the second end thereof. The opening of the stirring cover 11 faces the bottom of the device...

Embodiment 2

[0029] On the basis of the first embodiment above, optionally, as figure 1 As shown, the stirring mantle 11 is provided with an air outlet 111, which can discharge the gas in the stirring mantle 11 to the outside of the stirring mantle 11 to improve the flotation effect.

[0030] Such as figure 1 As shown, there are multiple exhaust air holes 111 on the stirring shell 11, and the multiple exhaust air holes 111 are evenly arranged along the circumferential direction of the stirring shell 11 to further improve the flotation effect.

[0031] Preferably, a flotation chamber 12 is provided at the bottom of the device body 8 .

[0032] The flotation chamber 12 includes a chamber body 122 and a chamber cover 121, and the chamber cover 121 is covered on the chamber body. In this embodiment, the flotation chamber 12 is integrally formed.

[0033] The cavity cover 121 is provided with a through hole, and the stirring cover 11 is positioned in the cavity 122 through the through hole, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com