Tool magazine with bidirectional tool taking function

A technology of tool magazine and tool holder, which is applied in the field of tool magazine, can solve the problems that the sealing performance of the tool magazine cannot be guaranteed, the time for automatic tool change is increased, the appearance is convex and unsightly, and the appearance is beautiful and exquisite, the sealing performance is good, and the energy saving cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

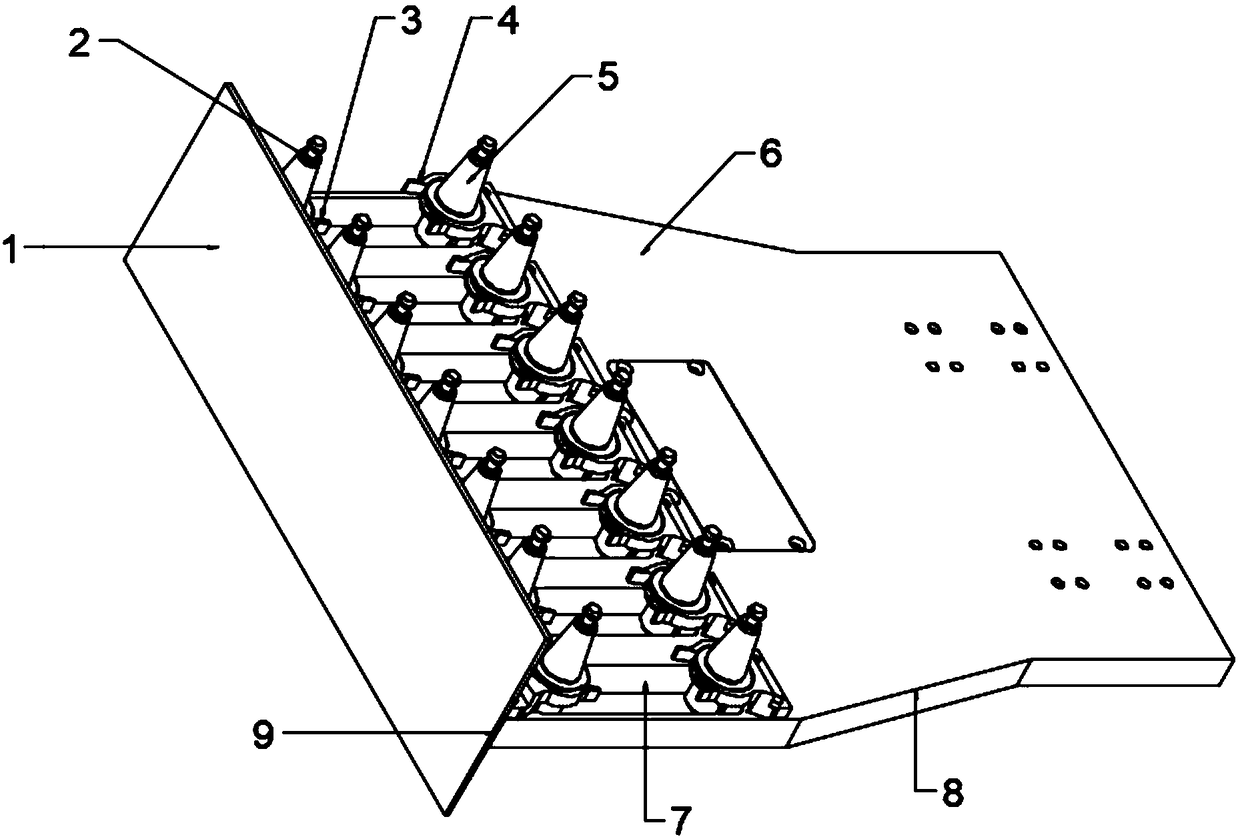

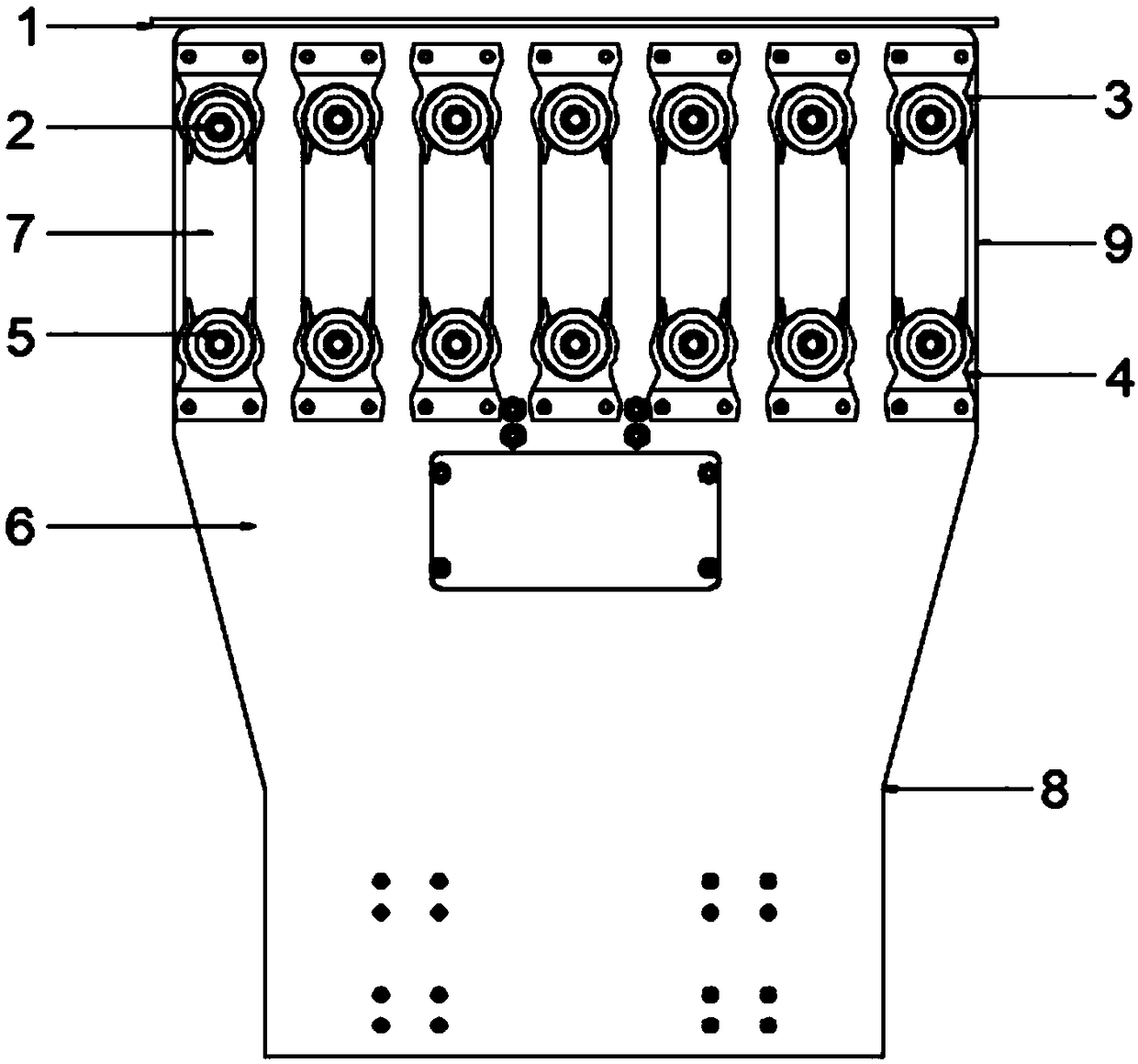

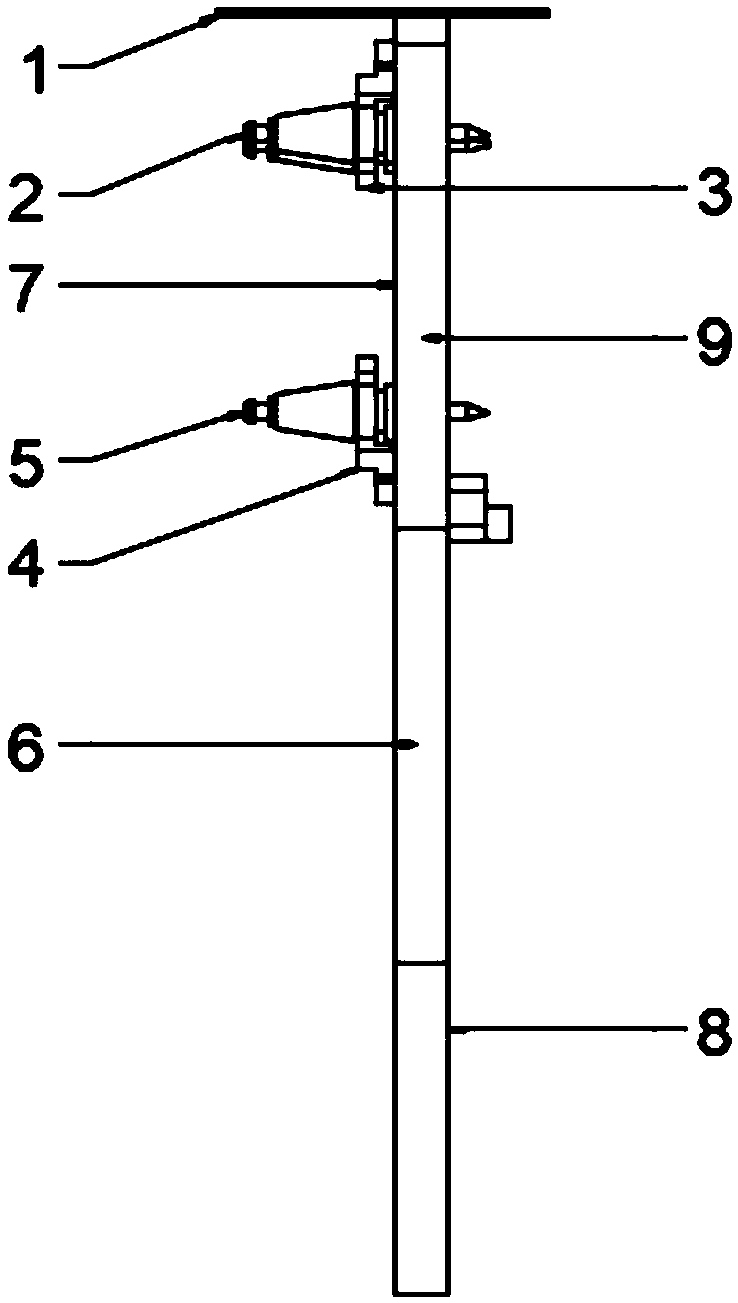

[0023] see figure 1 and figure 2 , in an embodiment of the present invention, a tool magazine capable of taking out knives in both directions includes a knife holder 8, and a knife magazine door 1 is fixed at the front end of the knife holder 8. The seat 8 is pushed out together with the tool magazine door 1, and the tool magazine door 1 and the tool seat 8 are integrally fixedly connected, and the knife magazine door 1 and the knife seat 8 are arranged perpendicular to each other. Rubber strips, in order to quickly take out the knife in two directions, the knife holder 8 is provided with two-way knife taking positions 7 distributed in an array.

[0024] Further, the cross-section of the two-way knife taking position 7 is rectangular, and the front row of knife heads 2 and the rear row of knife heads 5 are installed on the two-way knife taking position 7, and the front row of knife heads 2 are fixed and installed by the front row of knife holders 3 , the front row of knife ...

Embodiment 2

[0026] A tool magazine that can take out tools in both directions, please refer to Figure 1-3 , the embodiment of the present invention is further limited on the basis of embodiment 1.

[0027] Further, the knife seat 8 is composed of a lower knife seat 6 and an upper knife seat 9 , and the two-way knife picking position 7 is set on the upper knife seat 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com