Sling type crack detecting robot

A robot and sling-type technology, which is applied in the field of sling-type crack detection robots, can solve problems such as difficulty in movement, missing cracks, and misjudgment, and achieve the effect of firm cooperation and smooth driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

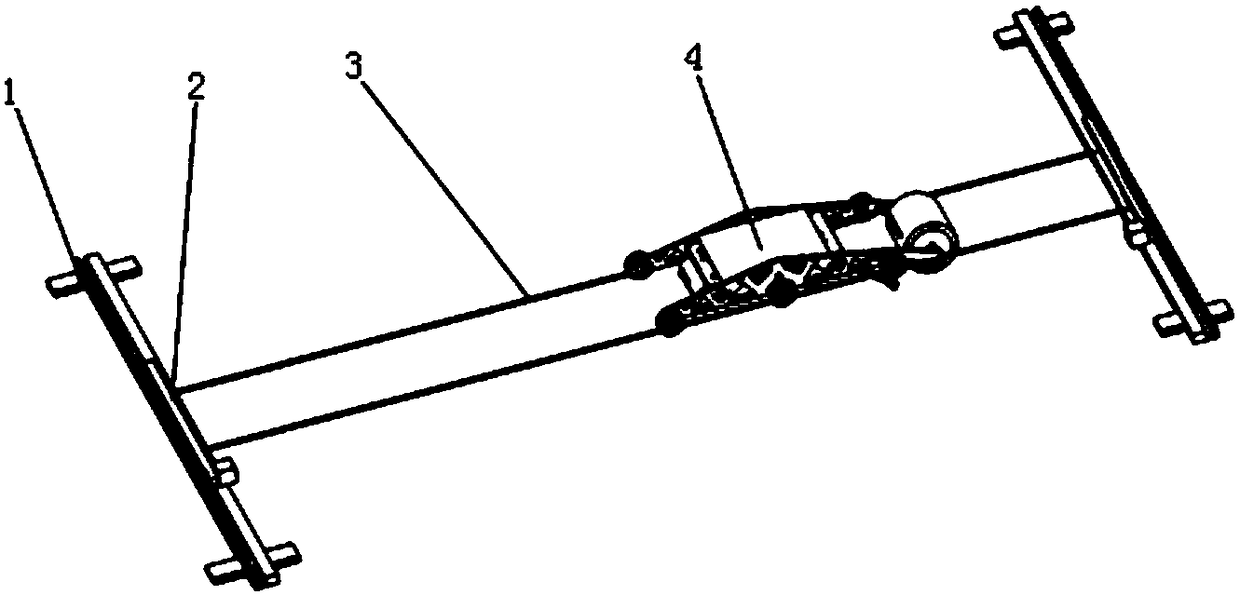

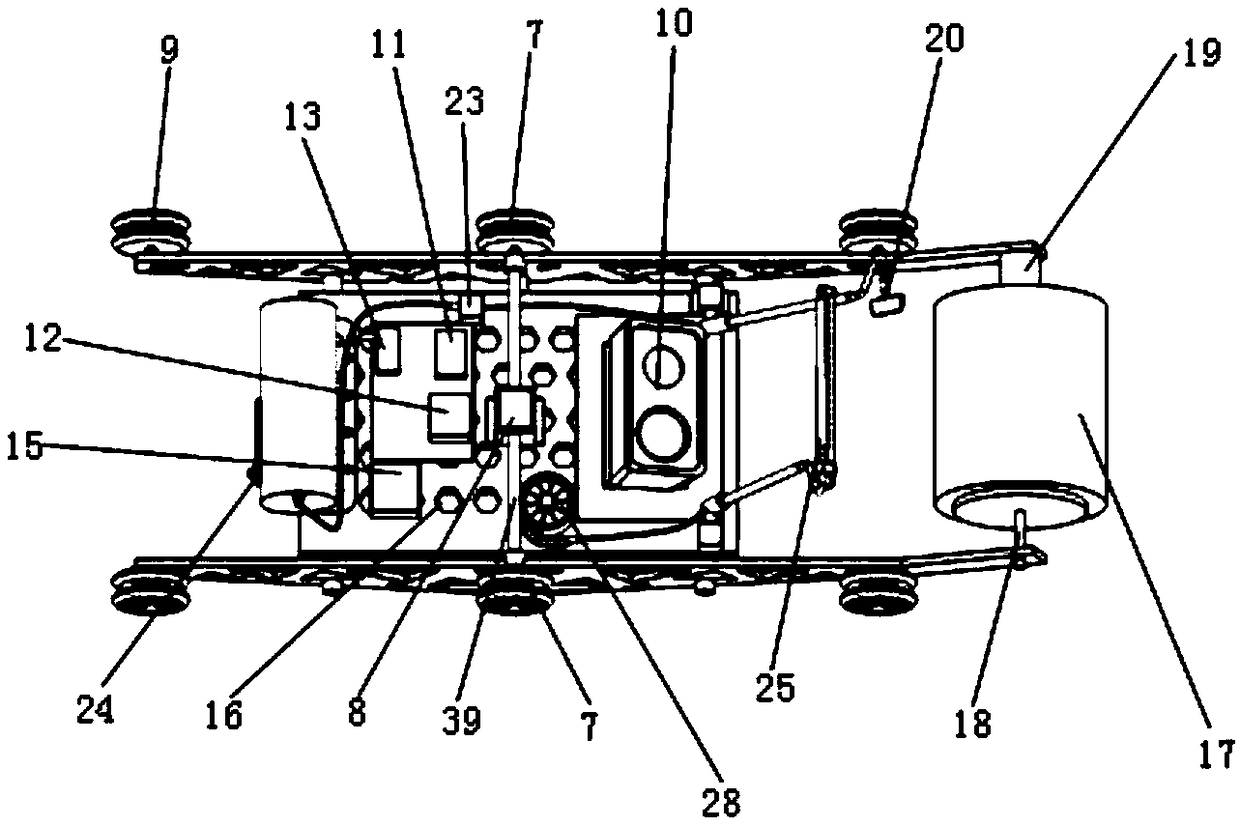

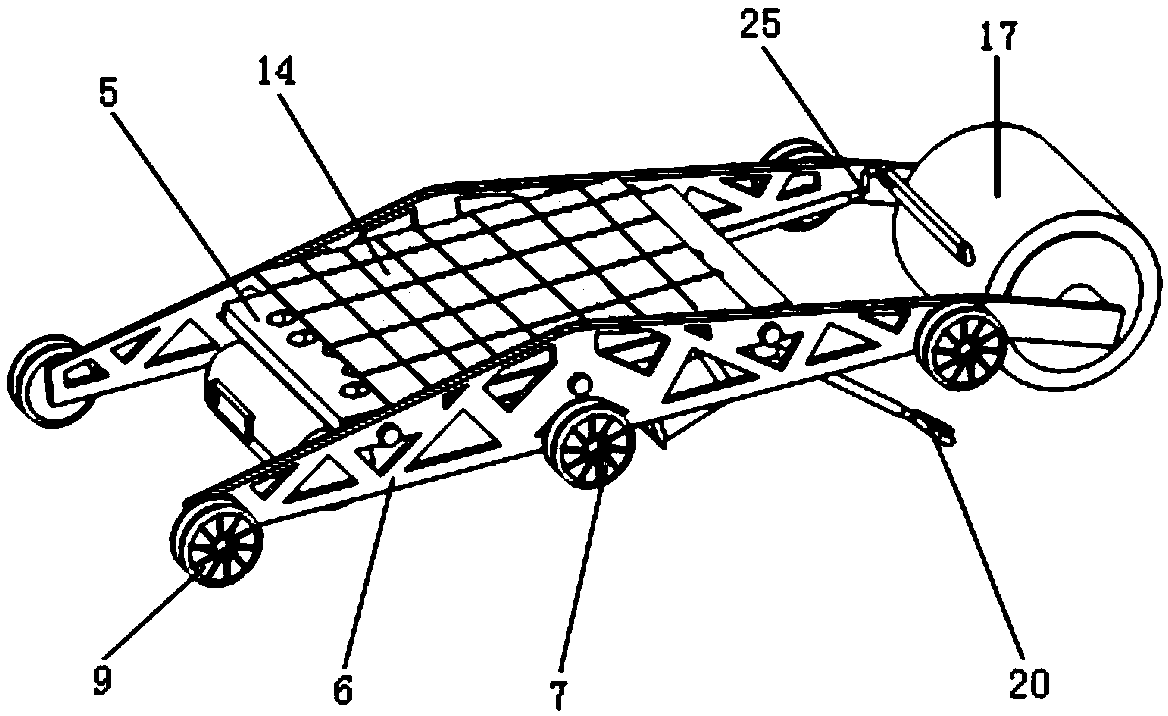

[0072] figure 1 A schematic structural diagram of a sling-type crack detection robot according to an embodiment of the present invention is shown; figure 2 A schematic diagram of the bottom structure of a probe vehicle according to an embodiment of the present invention is shown; image 3 A schematic diagram of the top structure of a probe car according to an embodiment of the present invention is shown; Figure 4 A schematic structural diagram of a temperature changing device according to an embodiment of the present invention is shown; Figure 5 A partial schematic diagram of a temperature changing device according to an embodiment of the present invention is shown; Figure 6 A schematic structural view of a hot air spray head according to an embodiment of the present invention is shown; Figure 7 It is a schematic diagram of the position of the snap ring according to an embodiment of the present invention; Figure 8 A schematic diagram of a control relationship accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com