A plywood bonding and shaping device

A shaping device and technology for plywood, which is applied in the direction of plywood press, veneer press, and the joining of wooden veneers, can solve the problems of low extrusion efficiency, uneven distribution of glue, inconvenient disassembly and maintenance, etc., and achieve complete shaping , The effect of speeding up the setting rate and preventing left and right shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

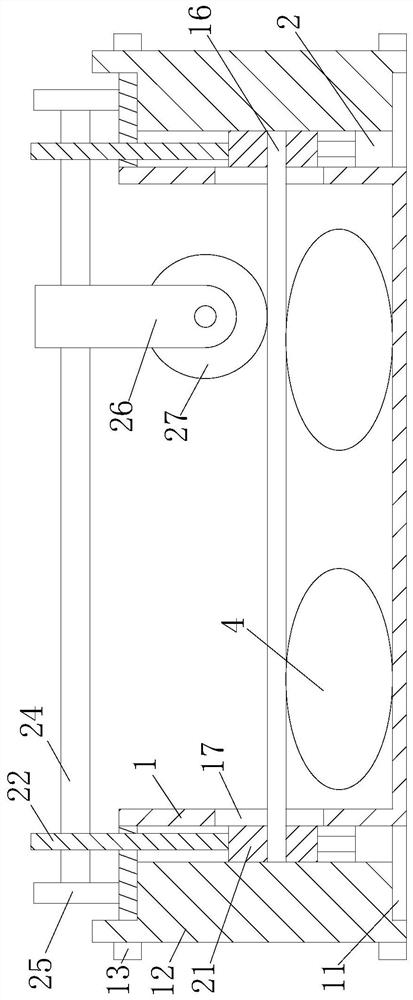

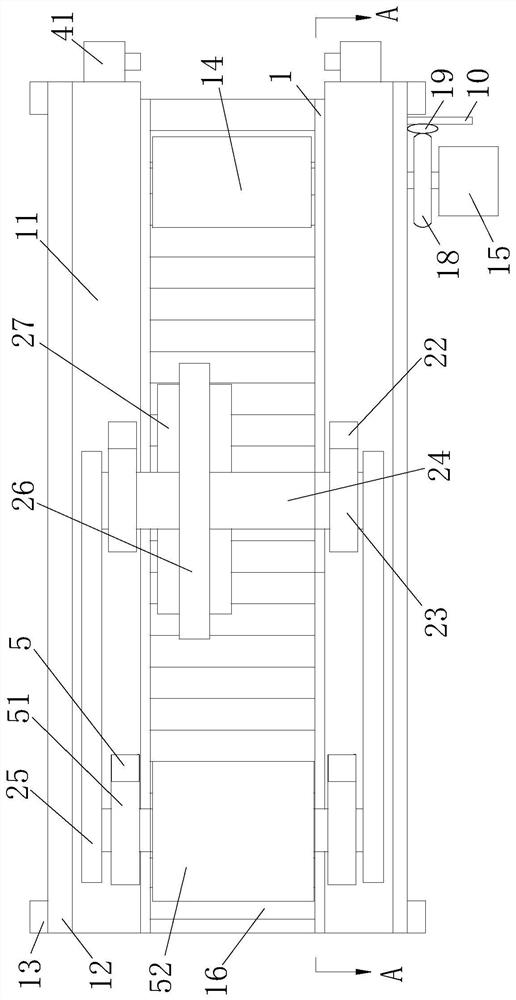

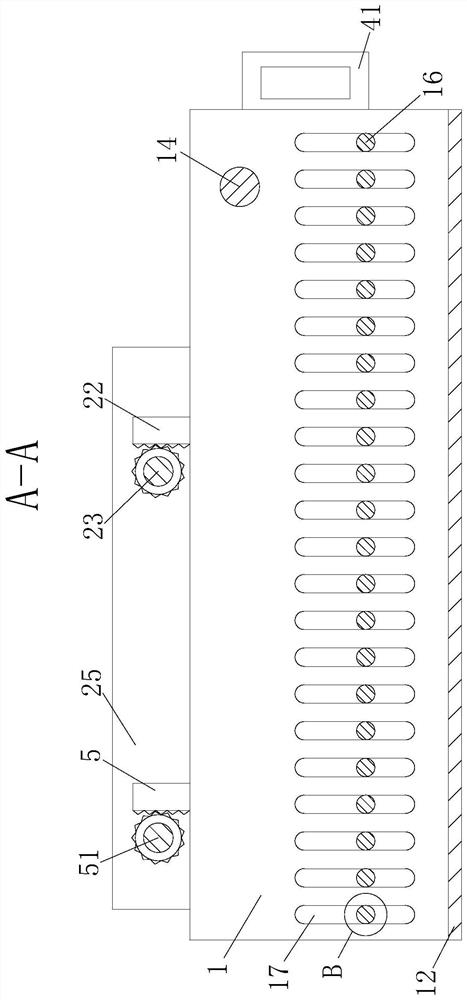

[0026] As an embodiment of the present invention, a first pneumatic cylinder 2 fixedly connected to the outer side wall of the frame body 1 is provided between the frame body 1 and the two engaging plates 12; the first pneumatic cylinder 2 is vertically set, and the driving end is fixedly connected with a brake block 21; the ends of the two brake blocks 21 away from the first pneumatic cylinder 2 are fixedly connected with a vertically arranged first rack 22; the first rack 22 is set through the frame body 1, and a first gear 23 meshing with the first rack 22 is provided above the dismounting plate 11; the upper surface of the frame body 1 is fixedly connected with two fixed plates 25 parallel to each other; The fixed plates 25 are all vertically arranged on the upper surface of the frame body 1; the worm 24 is rotatably connected between the two fixed plates 25; the two first gears 23 are respectively fixedly sleeved on the two ends of the worm 24; The worm 24 is slidingly sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com