Automobile 3-fold luggage case shelf part and manufacturing method thereof

A manufacturing method and a technology for a luggage case are applied in the field of auto parts, and can solve the problems of being unfavorable for the storage space of the car luggage, not having the parts of the luggage rack, and being unfavorable for the storage of the parts of the luggage rack, and the like. Good emission performance and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

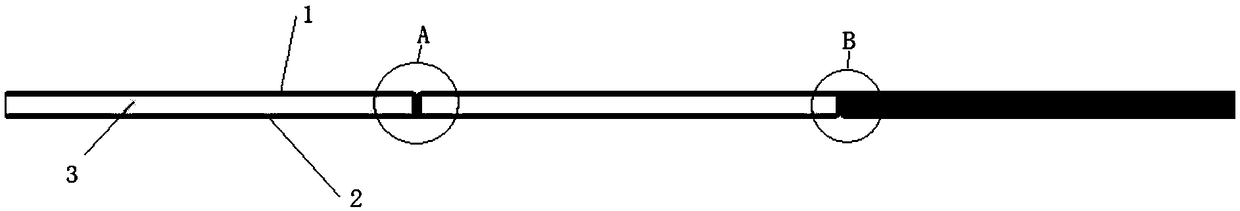

[0032] A method for manufacturing a three-fold luggage shelf part for automobiles, comprising punching of fabrics, manufacturing of PU paper honeycomb panels, glue spraying and bonding, and assembling. The specific steps are as follows:

[0033] a. Fabric punching

[0034] (1) The knitted style carpet fabric is the surface fabric 1 and the bottom fabric 2. This style of fabric was originally used in imported high-end models. The surface of the fabric is relatively fine and smooth. The weight per unit area of the knitted carpet is about: 300g / m 2 ,

[0035] (2) Die the above-mentioned fabrics into specified sizes using punching equipment and customized punching cutters.

[0036] b. Manufacture of PU paper honeycomb panel

[0037] (1) The surface glass fiber layer, the paper honeycomb board, and the bottom glass fiber layer are bound together in order;

[0038] (2) Use the manipulator to pick up the bound materials, and spray PU on the upper and lower surfaces;

[0039] (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com