Double-side anti-delamination sandwich panel with oblique ribs and its application, connection and preparation method

A sandwich panel and oblique rib technology, which is applied in the field of double-sided anti-delamination sandwich panels and their preparation, can solve the problems affecting the service life and safety of ships, and the delamination of sandwich panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

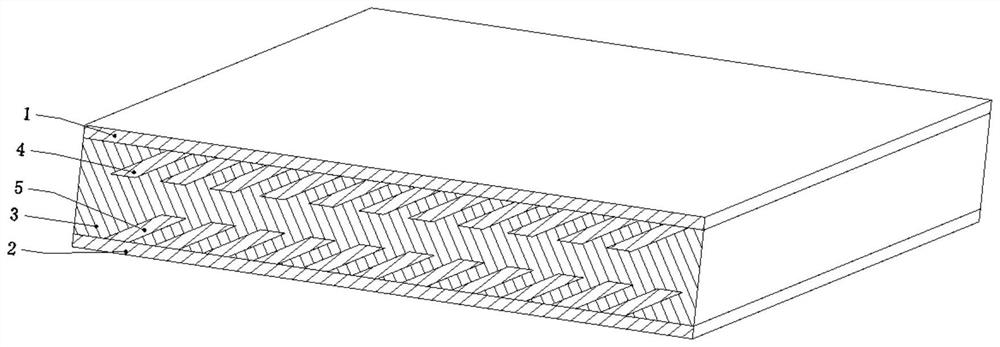

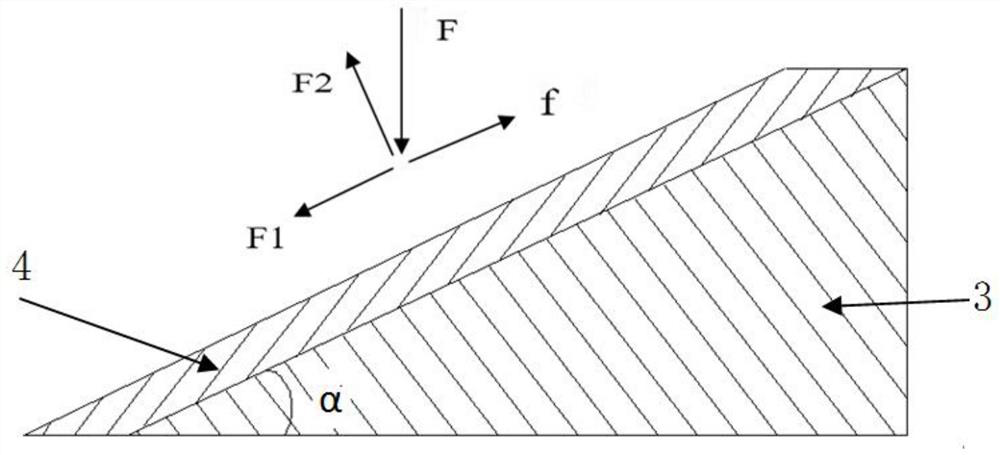

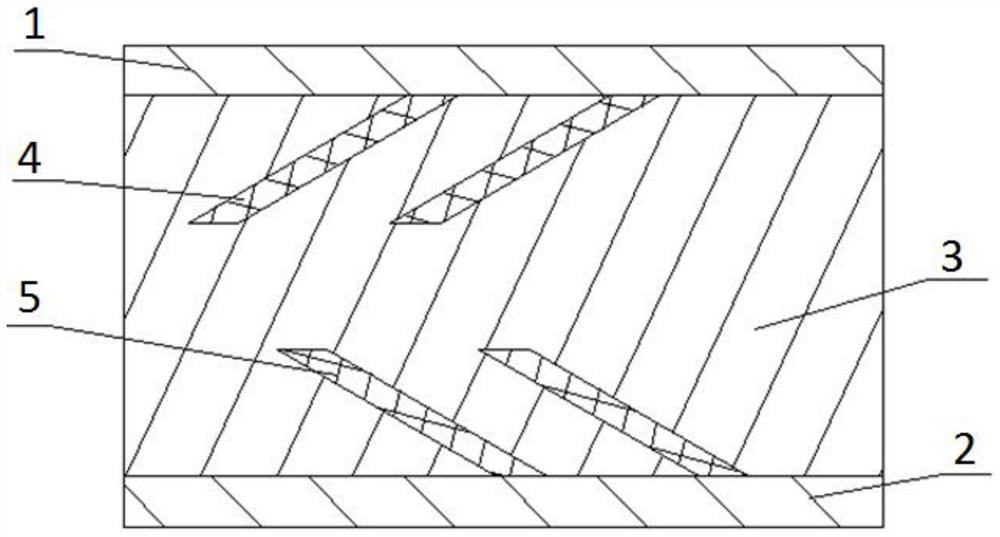

[0088] like Figure 8 As shown, the double-sided anti-delamination sandwich panel with oblique ribs in Example 1 includes an upper panel 1 , a lower panel 2 , a core material 3 , an upper rib 4 and a lower rib 5 . Among them, several upper ribs 4 are arranged obliquely and parallelly on the inner side of the upper panel 1, and several lower ribs 5 are arranged obliquely and parallelly on the inner side of the lower panel 2, the connection mode of the upper ribs 4 and the upper panel 1 And the connection mode of lower rib 5 and upper panel 2 is welding. The core material 3 is poured into the gap between the upper and lower panels and the upper and lower ribs, so that the components of the sandwich panel are combined to form a whole.

[0089] Wherein the upper panel 1 and the lower panel 2 are all selected A3 steel plate, the core material 3 of the present invention is selected nylon material, and the upper rib 4 and the lower rib 5 of the present invention are also selected A3...

Embodiment 2

[0094] like image 3 As shown, the double-sided anti-delamination sandwich panel with oblique ribs in Example 2 includes an upper panel 1 , a lower panel 2 , a core material 3 , an upper rib 4 and a lower rib 5 . Among them, several upper ribs 4 are arranged obliquely and parallelly on the inner side of the upper panel 1, and several lower ribs 5 are arranged obliquely and parallelly on the inner side of the lower panel 2, the connection mode of the upper ribs 4 and the upper panel 1 And the connection mode of lower rib 5 and upper panel 2 is pouring. The core material 3 is poured into the gap between the upper and lower panels and the upper and lower ribs, so that the components of the sandwich panel are combined to form a whole.

[0095] Wherein the upper panel 1 and the lower panel 2 are all selected A3 steel plate, the core material 3 of the present invention is selected nylon material, and the upper rib 4 and the lower rib 5 of the present invention are also selected A3 ...

Embodiment 3

[0100] The sandwich panel in Example 3 includes an upper panel 1 , a lower panel 2 , a core material 3 , an upper rib 4 and a lower rib 5 . Among them, several upper ribs 4 are arranged obliquely and parallelly on the inner side of the upper panel 1, and several lower ribs 5 are arranged obliquely and parallelly on the inner side of the lower panel 2, the connection mode of the upper ribs 4 and the upper panel 1 And the connection mode of lower rib 5 and upper panel 2 is pouring. The core material 3 is poured into the gap between the upper and lower panels and the upper and lower ribs, so that the components of the sandwich panel are combined to form a whole.

[0101]The dimensions of the sandwich panels in Example 3 are as follows: the thickness of the upper panel 1 and the lower panel 2 is 1.0 mm, the thickness of the upper rib 4 and the lower rib 5 is 2 mm, the distance between two adjacent ribs is 15 mm, and the height of the ribs is 1.0 mm. The thickness of the upper rib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com