A cutting machine with variable angle and variable pitch

A technology of variable pitch and unloading machine, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of different transfer distance and direction, unsuitable for continuous large-scale production, and inability to change products according to demand, etc., to achieve Reduced manpower input, high mechanical placement efficiency, and no jamming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer" ” refer to directions towards or away from the geometric center of a particular part, respectively.

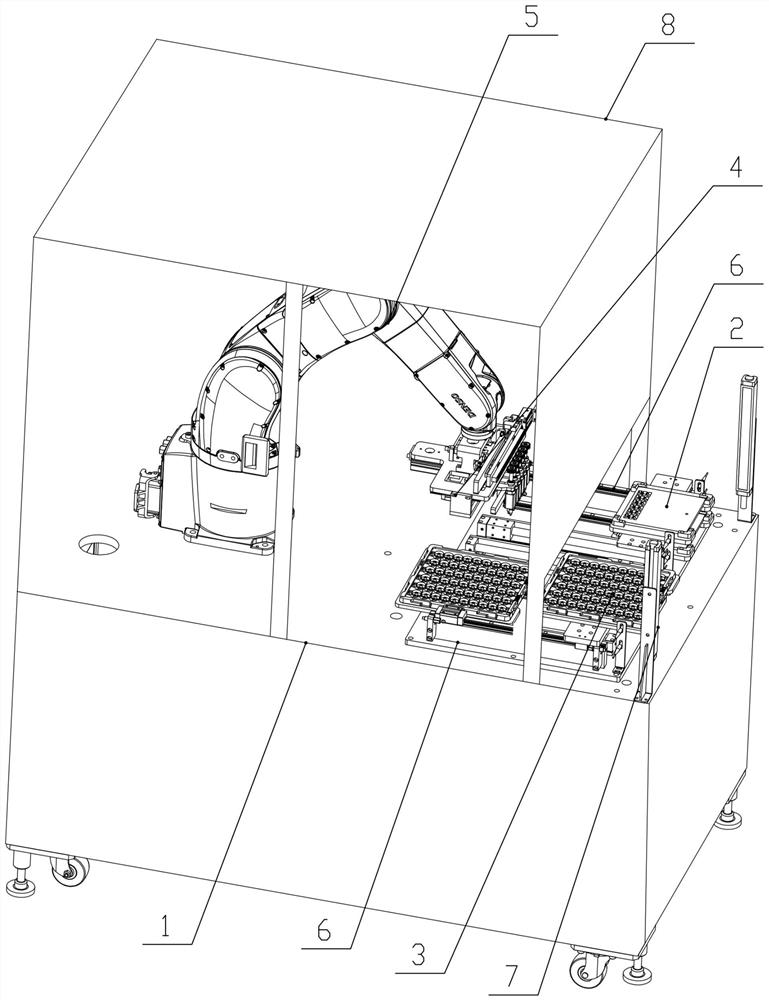

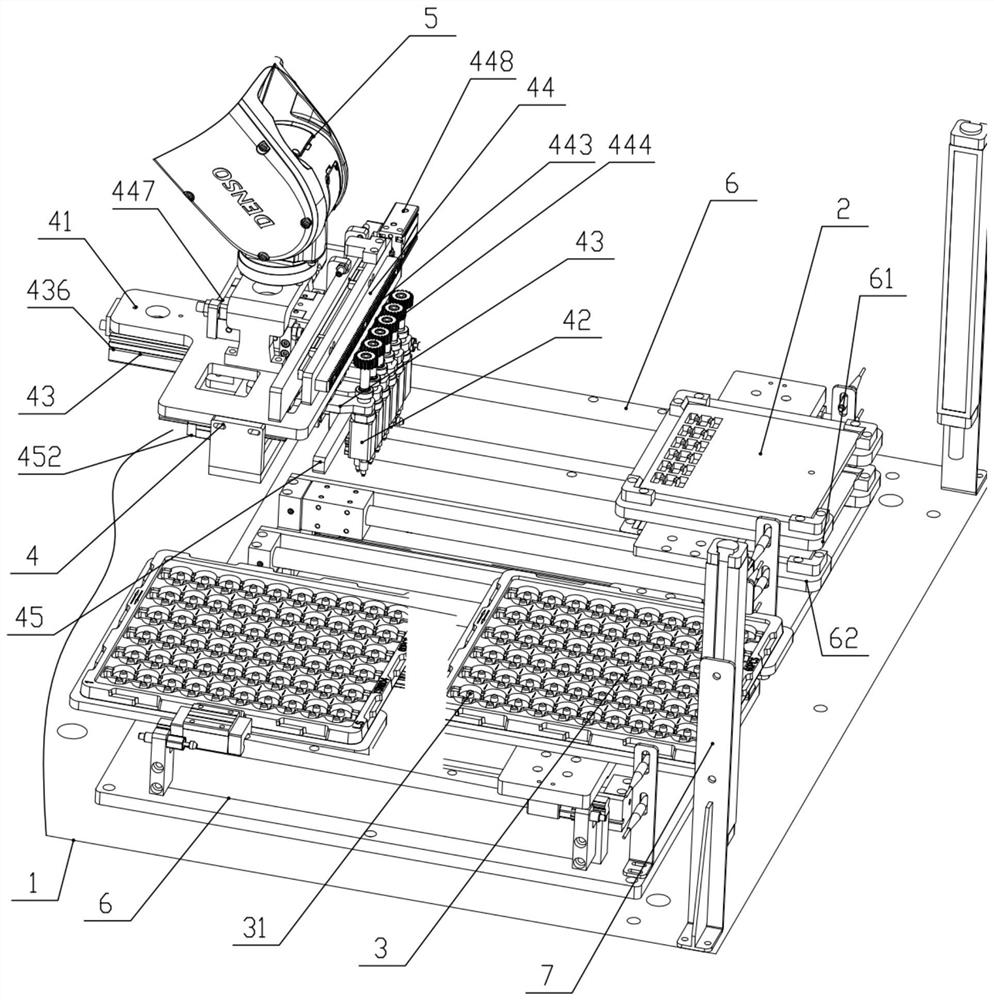

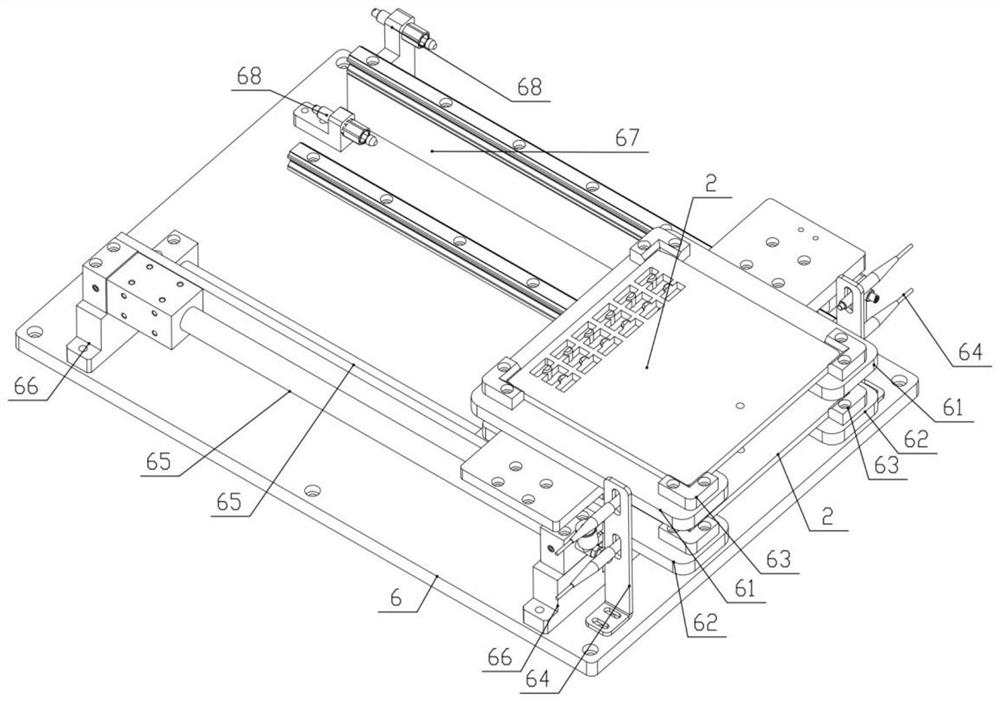

[0038] Figure 1 to Figure 8A blanking machine with variable angle and variable spacing is schematically shown according to an embodiment of the present invention. As shown in the figure, the variable-angle and variable-spacing blanking machine includes a worktable 1, a jig plate 2 and a blister plate 3 are respectively provided on both sides of the front end of the worktable 1, and the jig plate 2 is loaded with several columns of products. The blister plate 3 is provided with fixing grooves 31 in the same row. The angle of the product is different from the angle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com