Forming rolling machine used for film production

A winding machine and film technology, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of easy scattering to other places, affecting the precision of the film, wasting adhesives, etc., and shortening the winding time. time, improve the winding effect, add the effect of fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

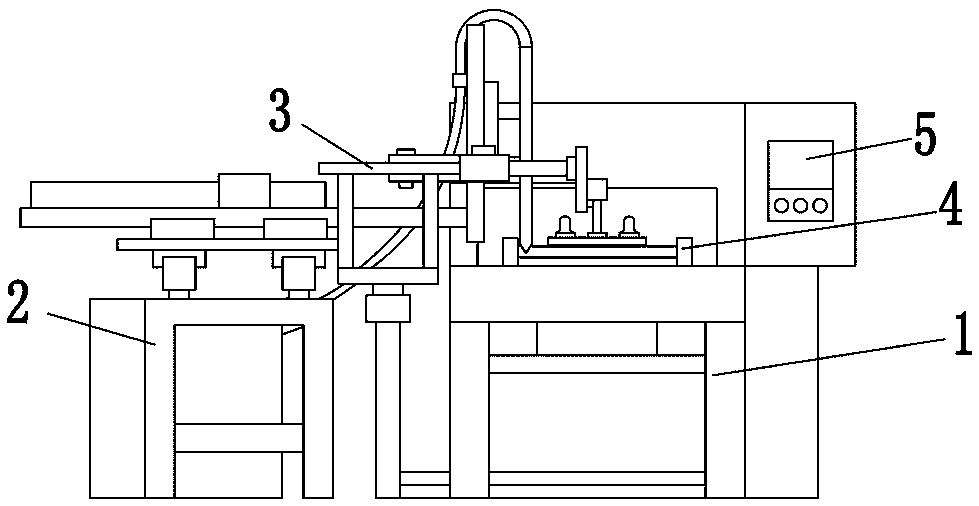

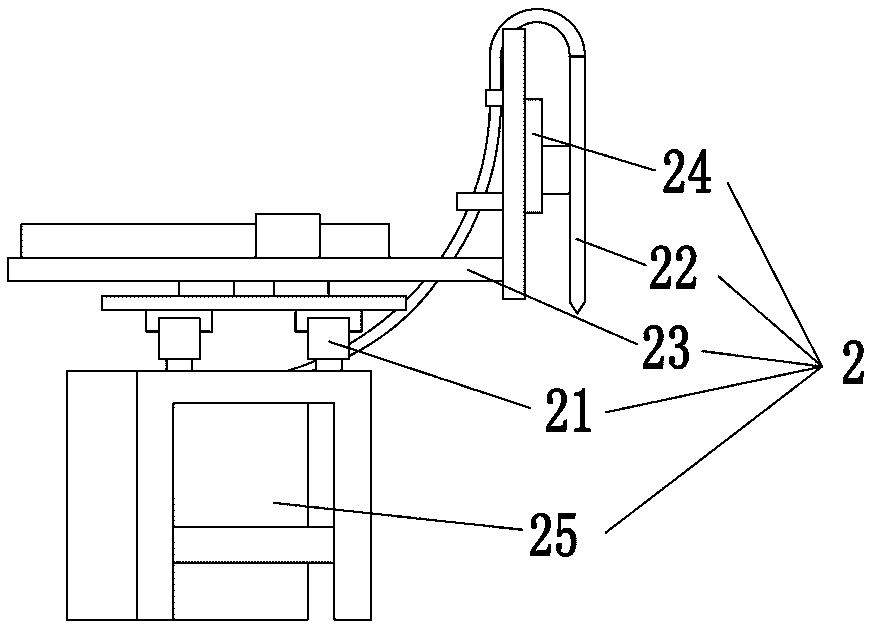

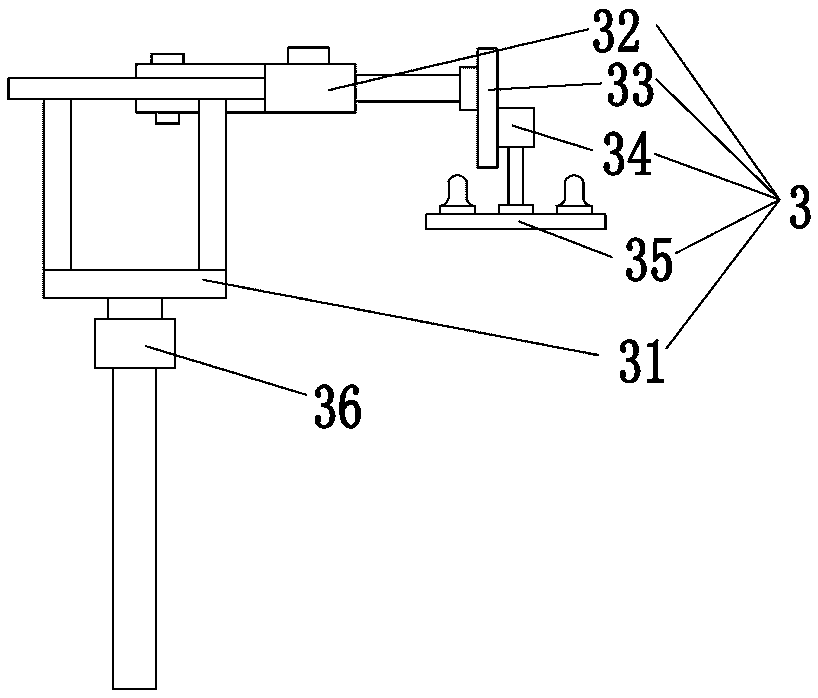

[0016] Such as Figure 1-4 As shown, a forming and winding machine for film production is characterized in that it includes a workbench 1 for placing the film, an adding mechanism 2 for adding adhesive to the film, and a pressing mechanism 3 for pressing the film. It also includes a winder 4 that winds and sticks a good film, and also includes a numerical control console 5 that controls each mechanism. The adding mechanism 2 is installed on the left side of the workbench 1, and the pressing mechanism 3 is installed on the adding mechanism 2. Between the workbench 1, the pressing mechanism 3 is close to the workbench 1, the winder 4 is installed at the rear end of the workbench 1, and the feeding end of the winder 4 is facing the workbench 1, so The numerical control console 5 is arranged on the right side of the workbench 1, and the pressing mechanism 3 includes a pressing frame 31, an electric propulsion device 32, a fixed plate 33, an electric lifting device 34 and a pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com