Construction method for controlling inclination and levelness of embedded section of tower crane

A technology of tower cranes and construction methods, applied in the direction of cranes, etc., to achieve the effects of enhancing stability, preventing stability degradation, and saving hoisting equipment occupation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: A construction method for controlling the inclination and levelness of embedded sections of a tower crane

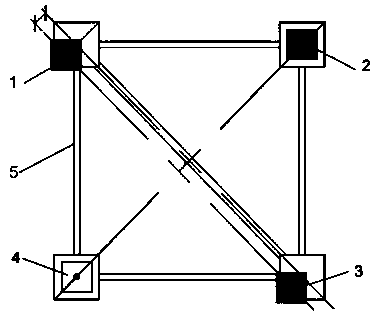

[0023] A certain project needs to install a QTZ70 tower crane. The tower crane adopts a fixed underframe structure with embedded joints. Its structure is as follows: figure 1 As shown, adopting the tower crane pre-embedded section inclination of the present invention and the levelness control construction method, specifically comprise the following steps:

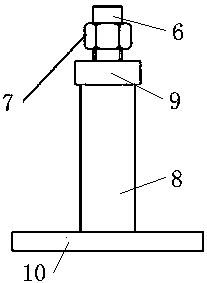

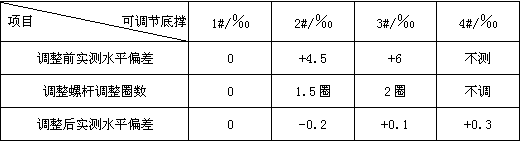

[0024] 1) The design thickness of the foundation concrete of 4 tower cranes with adjustable bottom support is 1300mm, and the "Instruction Manual for Tower Cranes" stipulates that the embedded joint depth is 900 mm. Therefore, the theoretical support height of the adjustable bottom support is calculated:

[0025] Theoretical support height = foundation concrete design thickness - embedded joint depth = 1300-900 = 400 mm,

[0026] The height of the finished four adjustable bottom supports should be a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com