A kind of electrorheological fluid and preparation method thereof

A technology of electrorheological fluids and insulating liquids, applied in the petroleum industry, additives, lubricating compositions, etc., can solve problems such as hindering the development of electrorheological fluids, and achieve the effects of excellent electrorheological properties, large specific surface area and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048]As another aspect of the technical solution of the present invention, a method of preparing a current variable liquid according to the present invention, comprising:

[0049]Provides a first mixing system including a metal organic frame material, a surfactant, and a solvent;

[0050]Provides a second mixing system containing organic titanate;

[0051]The second mixing system is mixed with the first mixing system, reacted to obtain a metal organic frame-titanium oxide complex;

[0052]The metal organic frame-titanium oxide complex is uniformly dispersed in the insulating liquid to obtain current variable fluid.

[0053]In some embodiments, the metal organic frame material, the mass ratio of the surfactant and the organic titanate is 1: 0.1 to 4: 3 to 20.

[0054]Wherein, the metal organic frame material can be any metal organic frame prepared by known methods known in the art.

[0055]In some embodiments, the metal organic frame material is preferably an organic-inorganic-inorganic hybrid particles...

Embodiment 1

[0078](1) Weigh 0.055 g mIL-101 (CR) (2483M specific surface area2 / g) in a mixed solvent dispersed in 55 ml of anhydrous ethanol / water (volume ratio 1: 0.1), then 0.0055 g sodium dodecyl benzene sulfonate, the suspension A is obtained;

[0079](2) 0.5 g of tetrabut ester is dissolved in 50 ml of anhydrous ethanol, and the solution B is obtained.

[0080](3) The solution B was added dropwise to the solution A, and the mixture was stirred after four hours and then allowed to stand for 10 hours; filtered the precipitate, washed, dried to give the required MIL-101 ( Cr) - Titanium oxide complex particles.

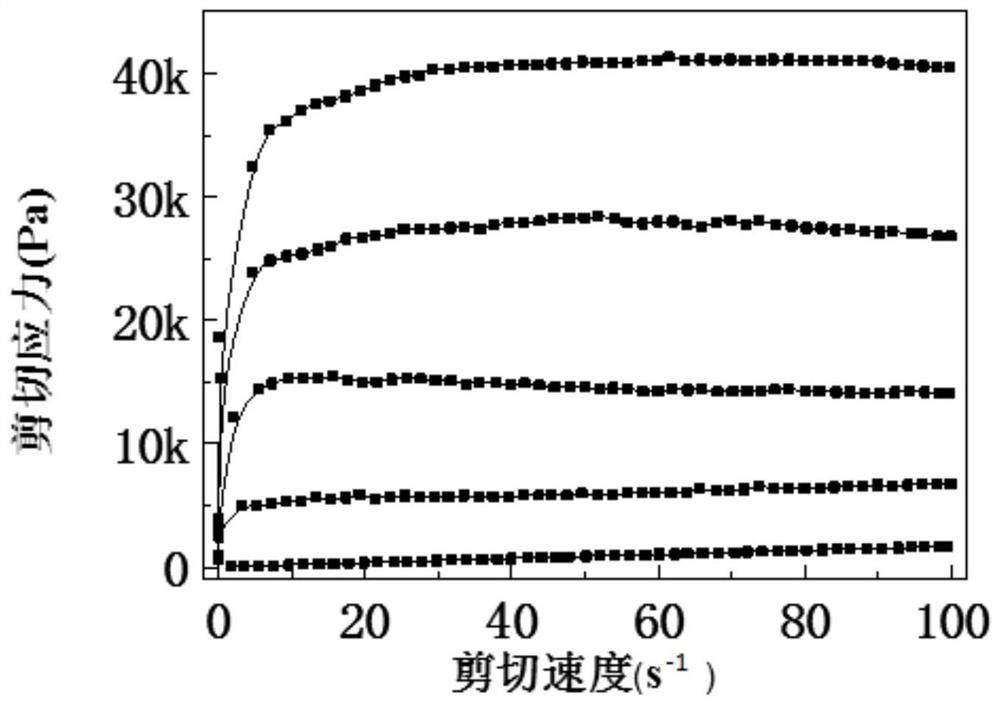

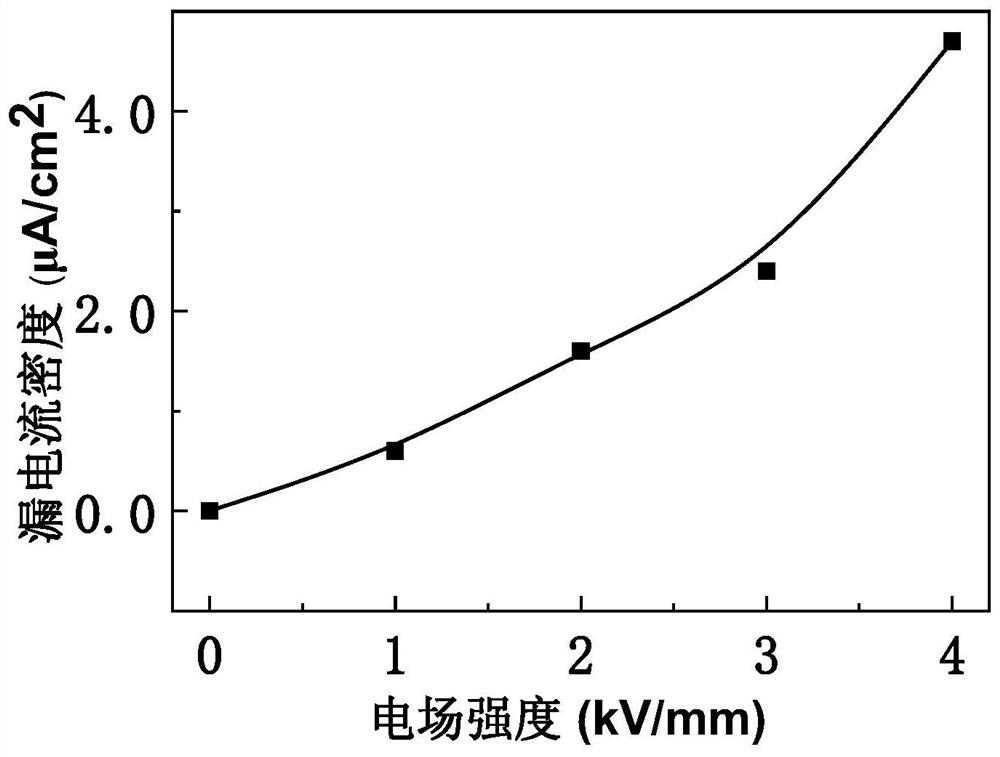

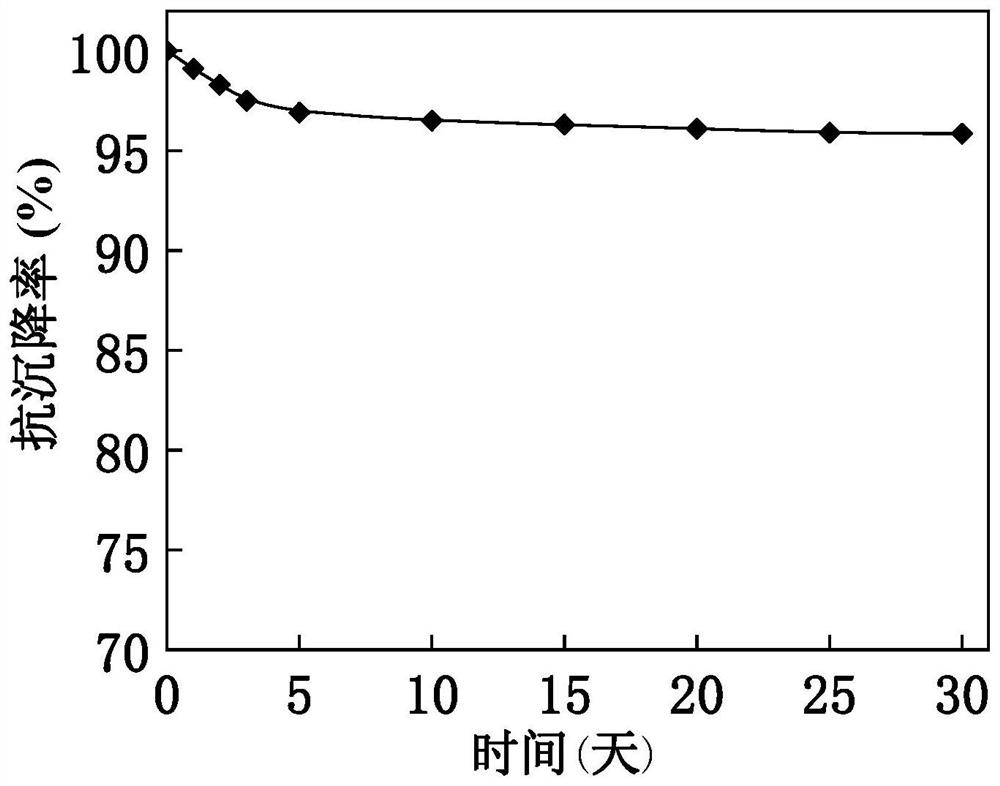

[0081](4) Disperse the complex particles obtained described above in silicone oil, configured as a mass fraction of 40% by weight of MIL-101 (CR) -toozipide-based current variable fluid. Such asFigure 1 - Figure 3 As shown, the current variable fluid is in the electric field of 4kV / mm, the shear speed is 100s-1When the dynamic shear stress is 40.5 kPa, the leakage current density is 4.5μ...

Embodiment 2

[0083](1) Weigh 0.084G mil-101 (Fe) (2265m specific surface area)2 / g) in a mixed solvent dispersed in 105 ml of anhydrous ethanol / water (volume ratio 1: 0.05), then 0.336 g of sodium dodecyl sulfate, the suspension A is obtained;

[0084](2) 0.25 g of ethyl titanate is dissolved in 50 ml of anhydrous ethanol and stirred for half an hour, and solution B is obtained.

[0085](3) The solution B was added dropwise to the solution A, and the mixture was stirred after four hours and then allowed to stand for 10 hours; filtered the precipitate, washed, dried to give the required MIL-101 ( FE) - Titanium oxide complex particles.

[0086](4) The complex particles obtained were dispersed in castor oil, and the mass fraction was 20% by weight of MIL-101 (Fe) -tooosidide composite current variable fluid. Such asFigure 4 - Figure 6 As shown, the current variable fluid is in the electric field of 4kV / mm, the shear speed is 100s-1When the dynamic shear stress is 39.8kPa, the leakage current density ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com