Cloth printing and dyeing device

A technology for fabrics and dyes, applied in the field of fabric printing and dyeing devices, can solve the problems of inability to adjust the liquid level of the printing and dyeing pools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

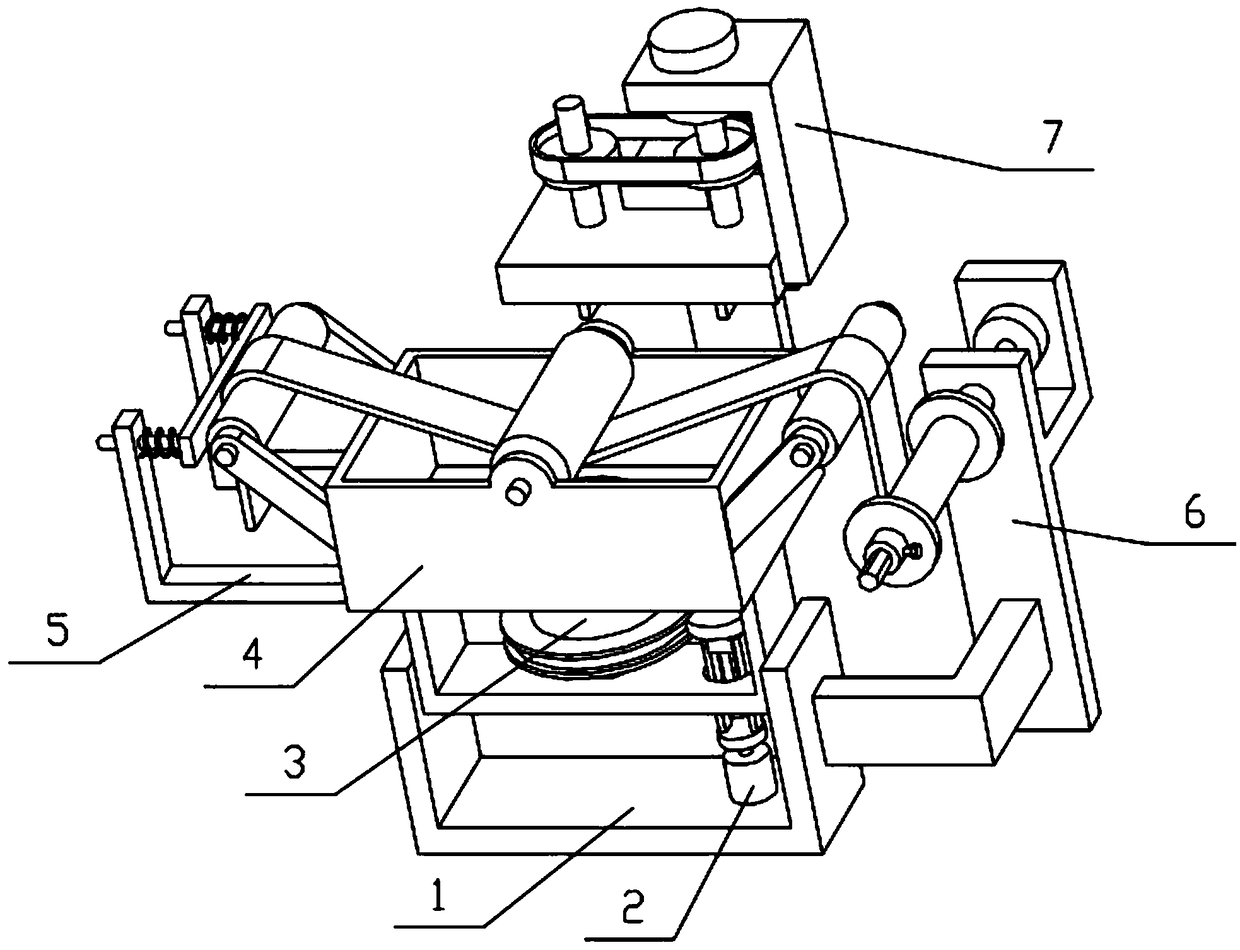

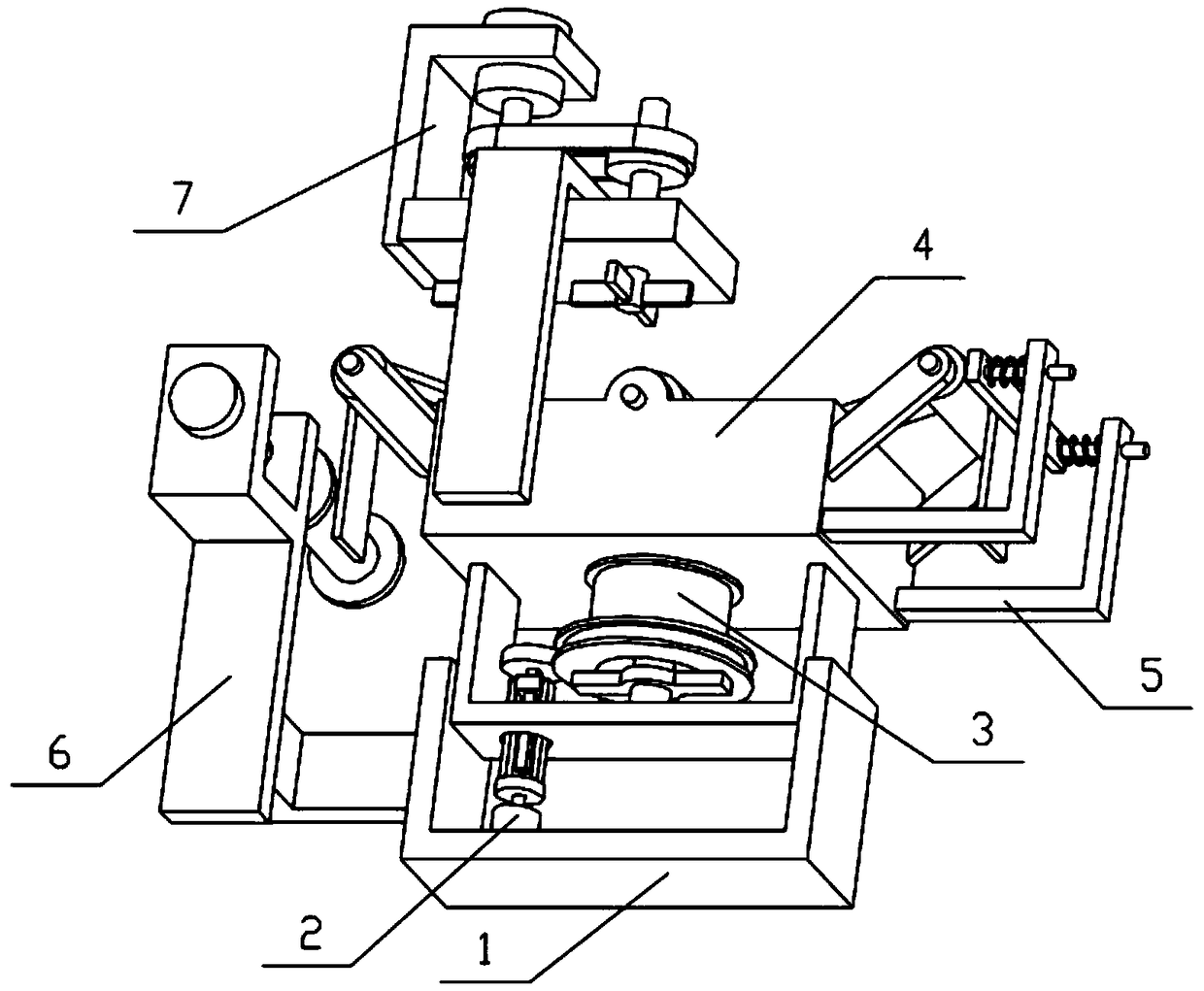

[0032] Combine below Figure 1-12 Describe this embodiment, the present invention relates to the field of printing and dyeing, more specifically a cloth printing and dyeing device, including a base 1, a driving assembly 2, a lifting cylinder 3, a dye container 4, a pressing assembly 5, a cloth receiving assembly 6 and a drying Component 7, the present invention can occupy the volume in the square box 4-1 through the lifting of the lifting cylinder 3. When the liquid level of the dye in the square box 4-1 is insufficient, the lifting cylinder 3 can be used to occupy the square box 4-1 The internal space makes the liquid level in the square box 4-1 rise, and it is not necessary to frequently add dyes with a suitable liquid level in the square box 4-1.

[0033] The driving assembly 2 is fixedly connected to the base 1, the lifting cylinder 3 is connected to the base 1 by threads, the driving assembly 2 is engaged with the lifting cylinder 3 for transmission, the dye container 4 i...

specific Embodiment approach 2

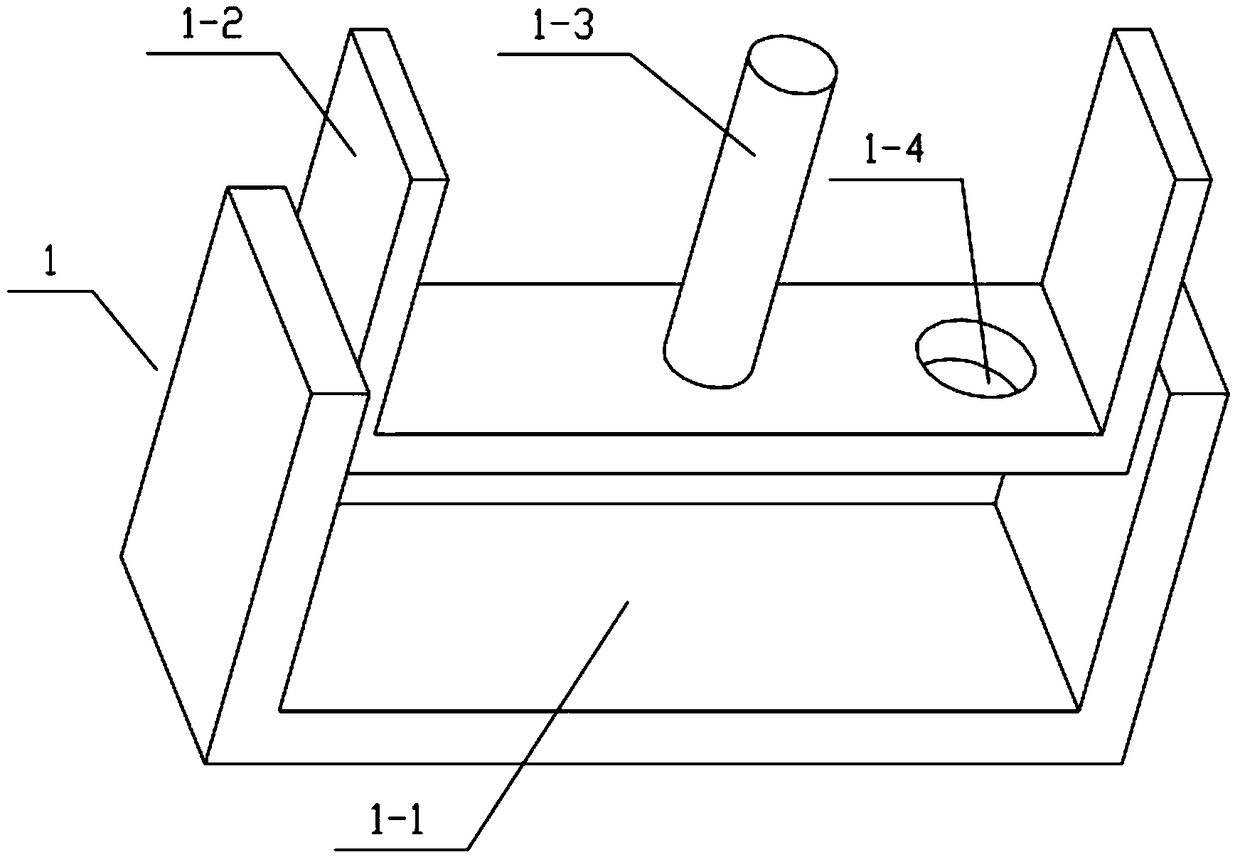

[0034] Combine below Figure 1-12Describe this embodiment, this embodiment will further explain Embodiment 1, the base 1 includes a door-shaped seat I1-1, a door-shaped seat II1-2, a threaded column 1-3 and a through hole 1-4, and the door-shaped seat I1 -1 and the door-shaped seat II1-2 are both in the shape of an inverted door, the door-shaped seat II1-2 is fixedly connected to the upper end of the door-shaped seat I1-1, and the threaded column 1-3 is fixedly connected to the middle position of the door-shaped seat II1-2 , the right side of the door-shaped seat II1-2 is provided with a through hole 1-4. Both the door-shaped seat I1-1 and the door-shaped seat II1-2 play a supporting role, and the function of the passing hole 1-4 is for the drive assembly 2 to pass through.

specific Embodiment approach 3

[0035] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain the second embodiment, the drive assembly 2 includes a motor I2-1, a disc 2-2, a connecting side column 2-3, a square column 2-4, a sliding sleeve 2- 5 and gear 2-6, the motor I2-1 is fixedly connected to the right side of the portal seat I1-1, the output shaft of the motor I2-1 is fixedly connected with the disc 2-2, and the upper end of the disc 2-2 is fixedly connected There are two connecting side columns 2-3, a sliding sleeve 2-5 is fixedly connected between the upper ends of the two connecting side columns 2-3, and a square column 2-4 is slidingly connected to the sliding sleeve 2-5, and the square column 2- The upper end of 4 is fixedly connected with gear 2-6, the output shaft of motor I2-1, disc 2-2 and gear 2-6 are coaxial, and the two connecting side columns 2-3 and square column 2-4 all pass through Holes 1-4. When the output shaft of the motor I2-1 rotates on its own...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com