Transverse locking structure for aluminum wood floors

A horizontal and floor technology, applied in the direction of building structure, floor, building, etc., can solve the problems of easy degumming, poor connection effect, loss of fixing function, etc., and achieve simple processing and production, good fixing effect and good fixing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

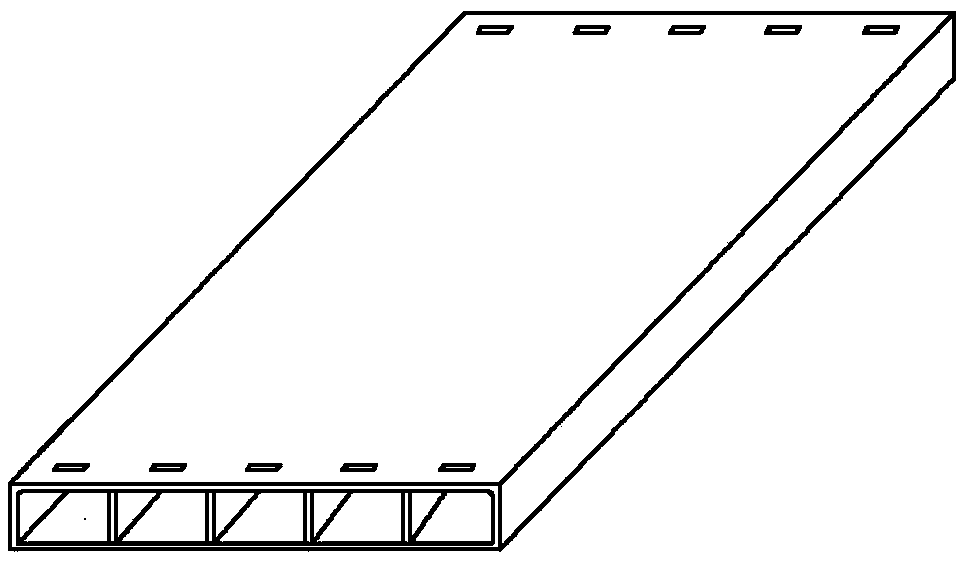

[0026] A horizontal locking structure for an aluminum-wood floor, which is used to connect adjacent floor boards. There are installation grooves on the opposite sides of the floor boards, and there are through clips on the upper side walls of the installation grooves. groove;

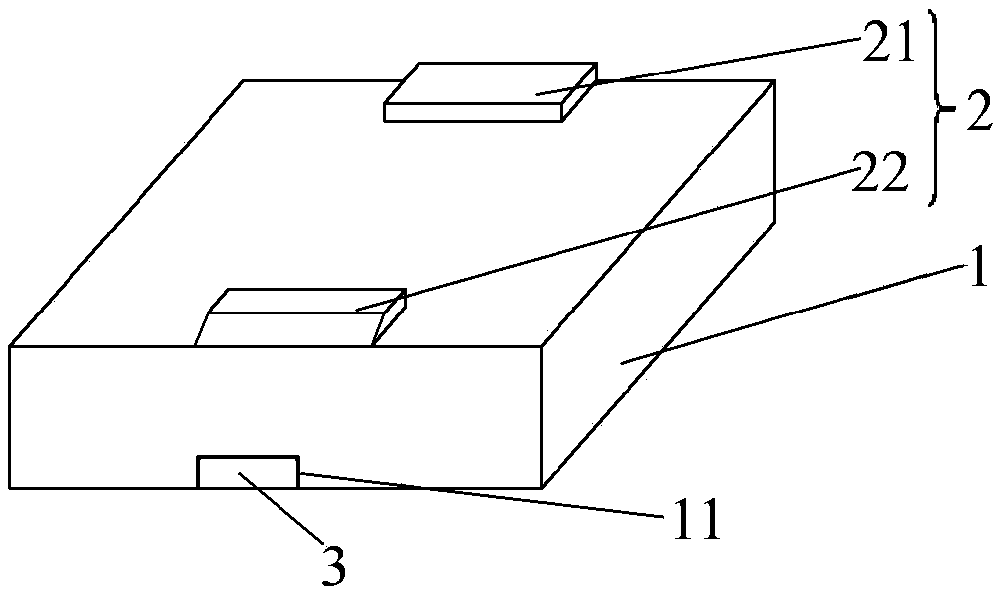

[0027] The horizontal locking structure of the aluminum-wood floor includes: the connector body 1, the clip 2 and the elastic member 3; where:

[0028] The clip 2 includes a clip one 21 and a clip two 22; the clip one 21 and the clip two 22 are integrally connected on the top surface of the connector body 1, and about the central axis of the connector body 1 parallel to the installation groove Symmetrically arranged; the first clip 21 is a cuboid, and the second clip 22 is a cuboid with an inclined section, and is set on the side away from the first clip 21 on the inclined section; the first clip 21 and the second clip 22 can be matched and installed in the card slot;

[0029] The central position of ...

Embodiment 2

[0031] The horizontal locking structure of the aluminum-wood floor includes: the connector body 1, the clamping strip 2, and the elastic member 3; among them:

[0032] The clip 2 includes a clip one 21 and a clip two 22; the clip one 21 and the clip two 22 are integrally connected on the top surface of the connector body 1, and about the central axis of the connector body 1 parallel to the installation groove Symmetrically arranged; strip one 21 is a cuboid, strip two 22 is a cuboid with an inclined section, and is set on the side away from strip one 21 on the inclined section; strip one 21 and strip two 22 can be matched and installed in the card slot;

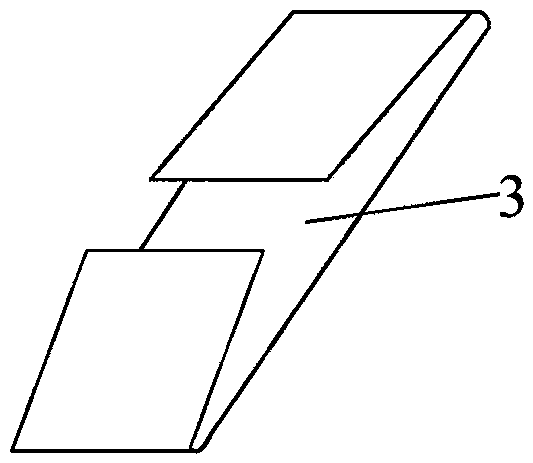

[0033] The central position of the bottom surface of the connector body 1 is provided with a groove 11; the elastic member 3 is matched and installed in the groove 11; wherein: the elastic member 3 is made by bending the two ends of a rectangular elastic metal material inward; the groove 11 has The two side walls, the elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com