A method for installing and fixing a crane traveling roller frame

A technology of lifting and fixing method, which is applied in assembly machines, workpiece clamping devices, metal processing equipment, etc., can solve the problem of inconvenient installation and fixing of the roller frame of the lifting crane, unfavorable construction site safety management, and unreliable fixing effect. Advanced problems, to achieve the effect of simple structure, convenient production and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

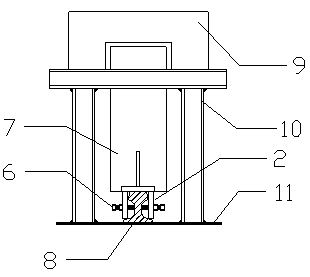

[0028] The installation and fixing method of the crane traveling roller frame of the present invention comprises the following steps:

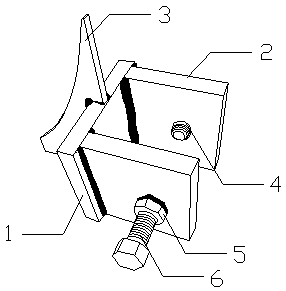

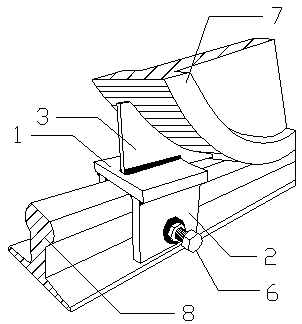

[0029] see now figure 1 , figure 1 It is a structural schematic diagram of a gantry clamp according to an embodiment of the present invention.

[0030] a. Manufacture portal frame fixture: Cut three steel plates with a thickness of 20 mm, a length of 150 mm, and a width of 150 mm. One top plate 1 and two side plates 2 are combined and welded to form a door shape. Holes of 25 mm are opened on both sides to the middle and bottom of the outer side of the plate. Weld the nut 5 of the 22mm bolt outside the through hole 4, and install the 22mm screw rod 6 on the nut to pass through the 25mm hole.

[0031] b. Make the fixed fixture baffle 3: Cut a steel plate with a thickness of 10mm, a length of 300mm, and a width of 150mm, make an arc cut along the diagonal according to the radius of the crane rail wheel, and then cut a gap of 150mm in length and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com