Oil suction device

An oil-absorbing belt and oil-scraping groove technology is applied in the fields of production fluids, wellbore/well components, and earth-moving drilling. The effect of easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

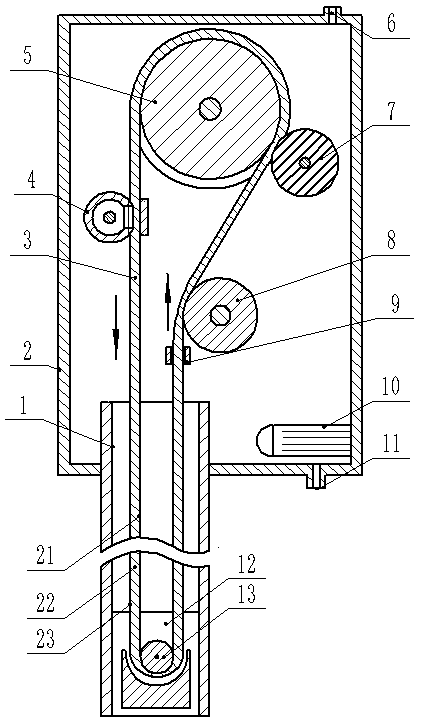

[0016] refer to figure 1 , including driving wheel 5, continuous oil-absorbing belt 3, weighted bearing 13 and housing 2, driving wheel 5 and squeezing wheel 7 are set in housing 2, squeezing wheel 7 is tangent to driving wheel 5, continuous oil-absorbing belt 3 is tight Set on the driving wheel 5 and the weighted bearing 13 inside the casing 1 placed below the liquid level of the crude oil 12, the casing 2 is sealed and connected with the casing 1, and the continuous oil absorption belt 3 is tightly placed on the driving wheel before the crude oil is extracted and lifted. On the wheel 5 and the weighted bearing 13, the weighted bearing 13 drives the continuous oil-absorbing belt 3 to gently lower into the casing 1 until it is immersed in the crude oil 12. The continuous oil absorption zone 3 in the crude oil 12 fully absorbs the crude oil 12 . Driven by the power, the drive wheel 5 rotates counterclockwise, driving the continuous oil-absorbing belt 3 to rotate counterclockwi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com