Control method for realizing accurate receiving of pipe jacking machine

A control method and technology of a pipe jacking machine, which are applied in the fields of earth-moving drilling, mining equipment, tunnels, etc., can solve the problem of easy existence of large blocks of concrete, and achieve the effect of increasing the reuse rate and reducing the construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

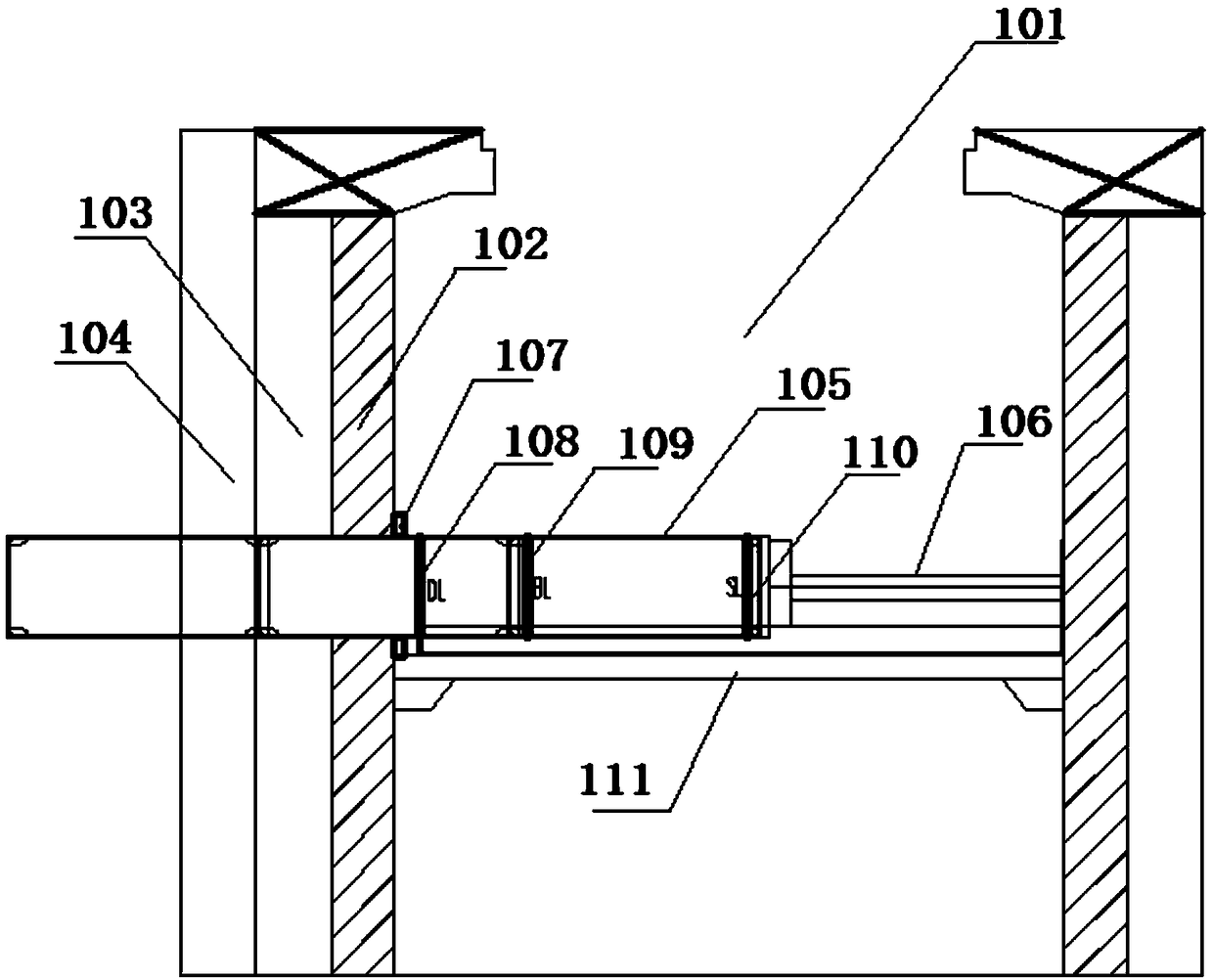

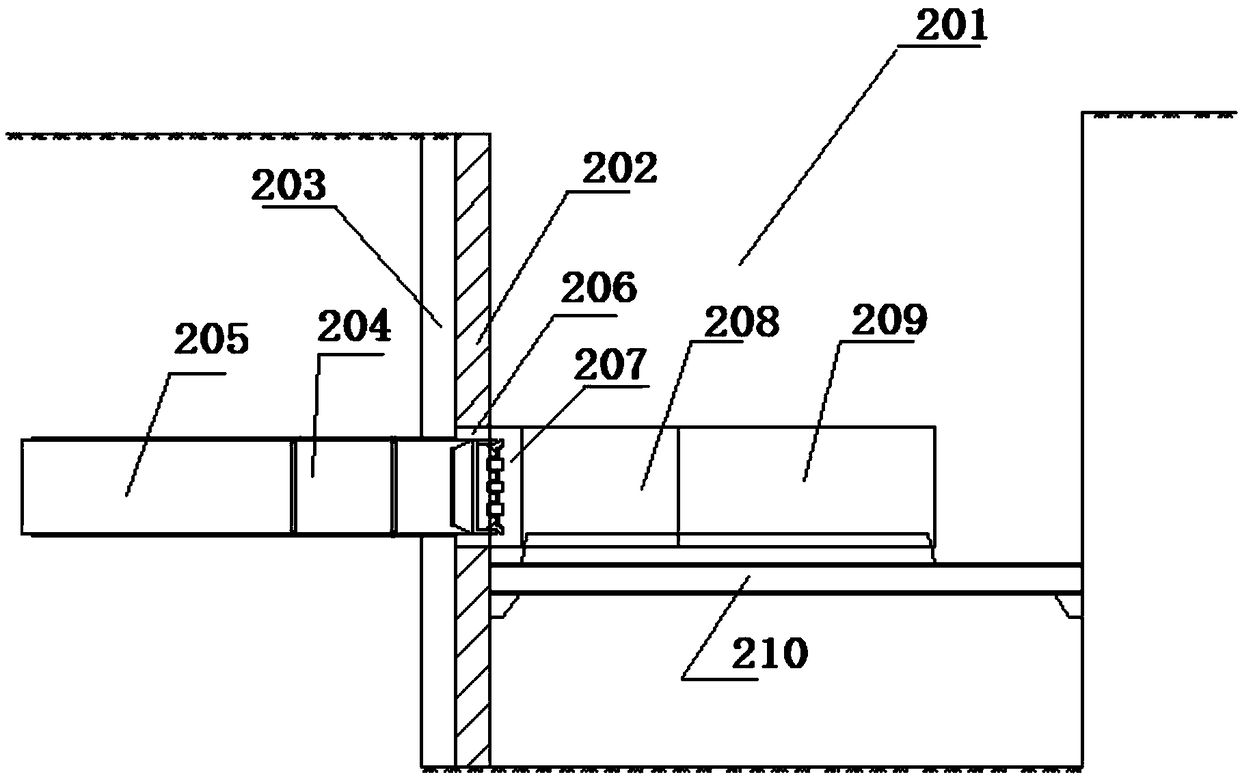

[0019] like figure 1 Shown is a schematic diagram of the present invention in the pipe curtain pipe jacking working well 101, wherein the operator uses the hydraulic jack 106 to jack the pipe joint to push the pipe jacking machine head 204 toward Figure II The pipe curtain in takes over the takeover device in the working well 201.

[0020] First prepare a set of pipe jacking machine receiving device, and embed the orifice pipe of the device in the opening wall of the receiving well. During the installation process of the orifice pipe, the position of the orifice pipe needs to be measured. , measure and adjust the axis of the pipe jacking machine to ensure that the pipe jacking machine can break the wall within the specified range, including using the pipe joint deceleration line 108, the pipe joint wall breaking line 109 and the pipe joint termination line 110 respectively through the calculation To determine the corresponding control node position, and perform the following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com