Winter firefighting pipeline intelligent temperature control device for construction site

A technology for fire-fighting pipelines and intelligent temperature control, which is applied in the direction of electric heating devices, pipeline heating/cooling, pipes/pipe joints/fittings, etc., which can solve the problems of potential safety hazards and large heating power consumption, so as to save economic costs and ensure The effect of fire-fighting water and reducing work energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

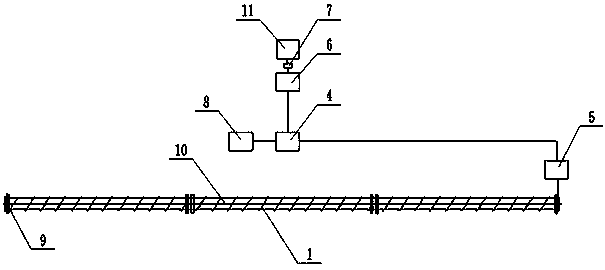

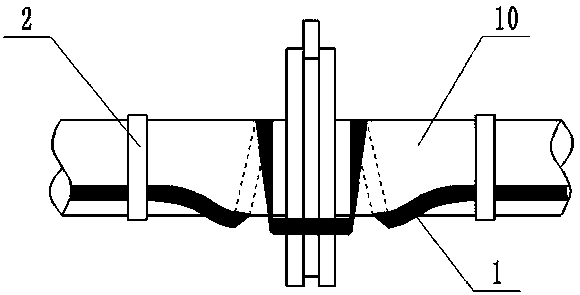

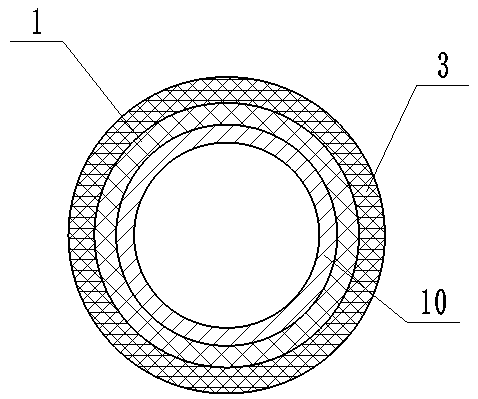

[0016] Such as figure 1 As shown, it is a schematic diagram of the overall connection circuit of a winter fire-fighting pipeline intelligent temperature control device used in the construction site of the present invention, including a self-limiting heating cable 1, a temperature control switch 4, a power junction box 5, a power distribution box 6, and a leakage current A protection device 7, a temperature sensor 8 and a sealed terminal box 9 at the end. The self-limiting thermoelectric heating cable 1 is wound on the fire-fighting pipeline 10 that needs to be kept warm, and the self-limiting thermoelectric heating cable 1 is connected to the temperature control switch 4 through the power junction box 5 , the temperature sensor 8 is placed in the atmosphere, connected to the temperature control switch 4 by wires, the temperature control switch 4 is connected to the leakage protection device 7 in the distribution box 6, and the leakage protection device 7 is connected to 220V, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com