Loop inductance winding machine

A toroidal inductor and winding machine technology, applied in coil manufacturing and other directions, can solve the problems of low winding efficiency, low winding quality, and uneven wiring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

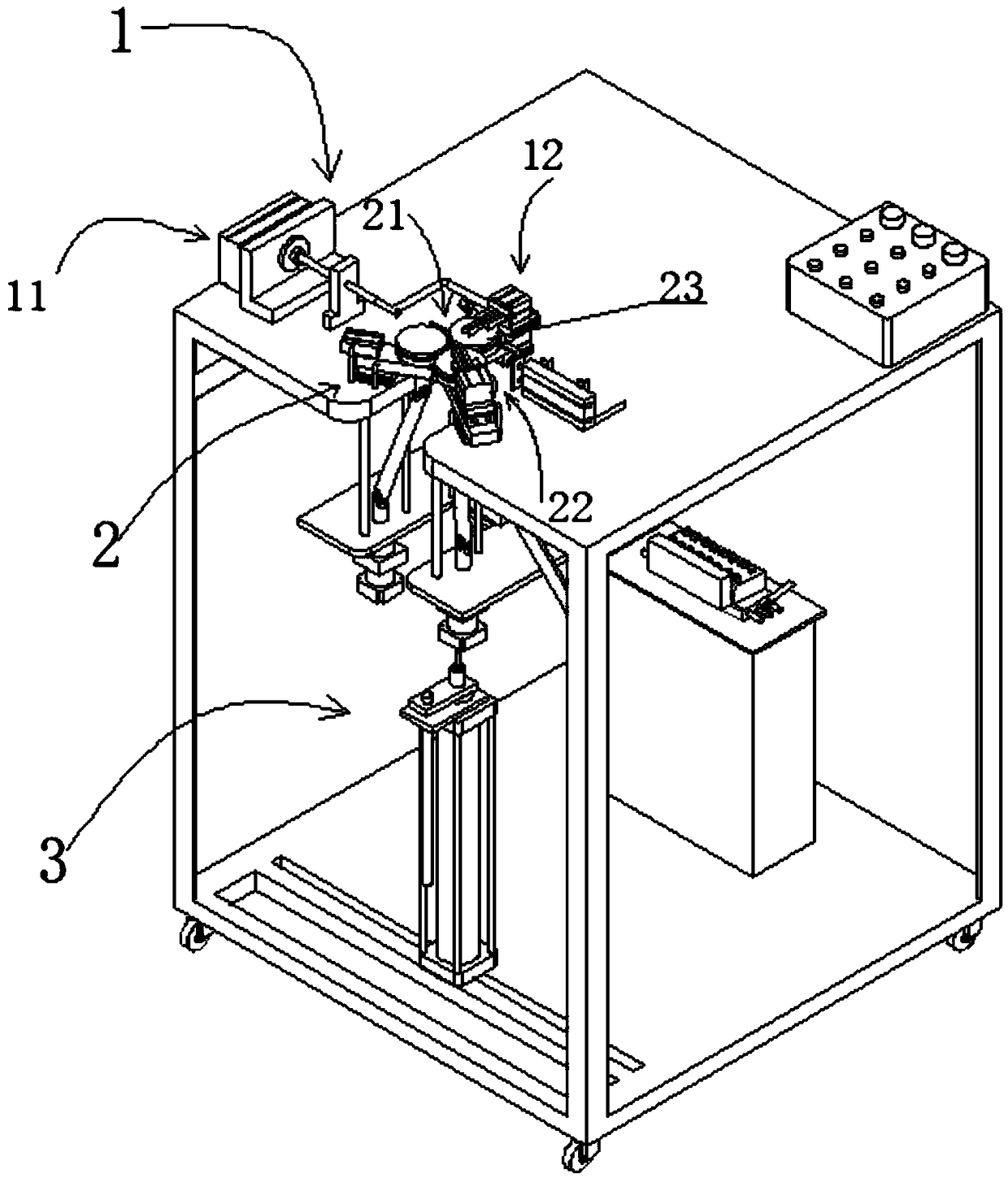

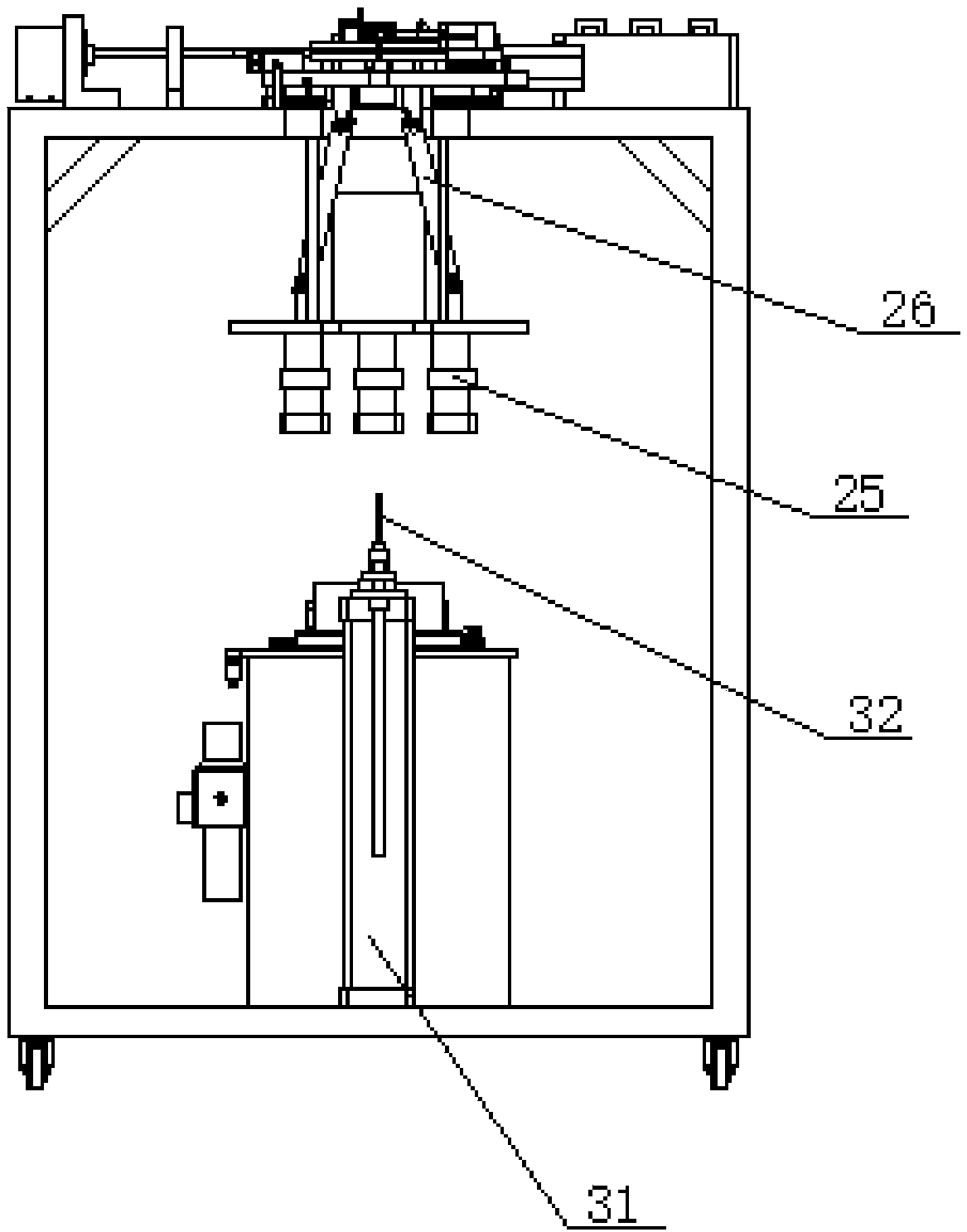

[0046] figure 1 A structural schematic diagram of a ring-shaped inductor winding machine provided in an embodiment of the present invention at a viewing angle, figure 2 A structural schematic diagram of a ring-shaped inductor winding machine provided in an embodiment of the present invention at a viewing angle, image 3 For a schematic view of the structure of the ring-shaped inductor winding machine provided by the embodiment of the present invention, please refer to Figure 1-3 As shown, the annular inductance winding machine of this embodiment includes a frame and a wire turning mechanism 1, a wire arranging mechanism 2 and a hooking mechanism 3 arranged on the frame. The annular inductance winding machine of this embodiment winds the copper wire on the magnetic ring.

[0047]The thread turning mechanism 1 includes a first driving structure 11 and a first clamping structure 12 connected to the first driving structure 11; in this embodiment, the first driving structure 11...

Embodiment 2

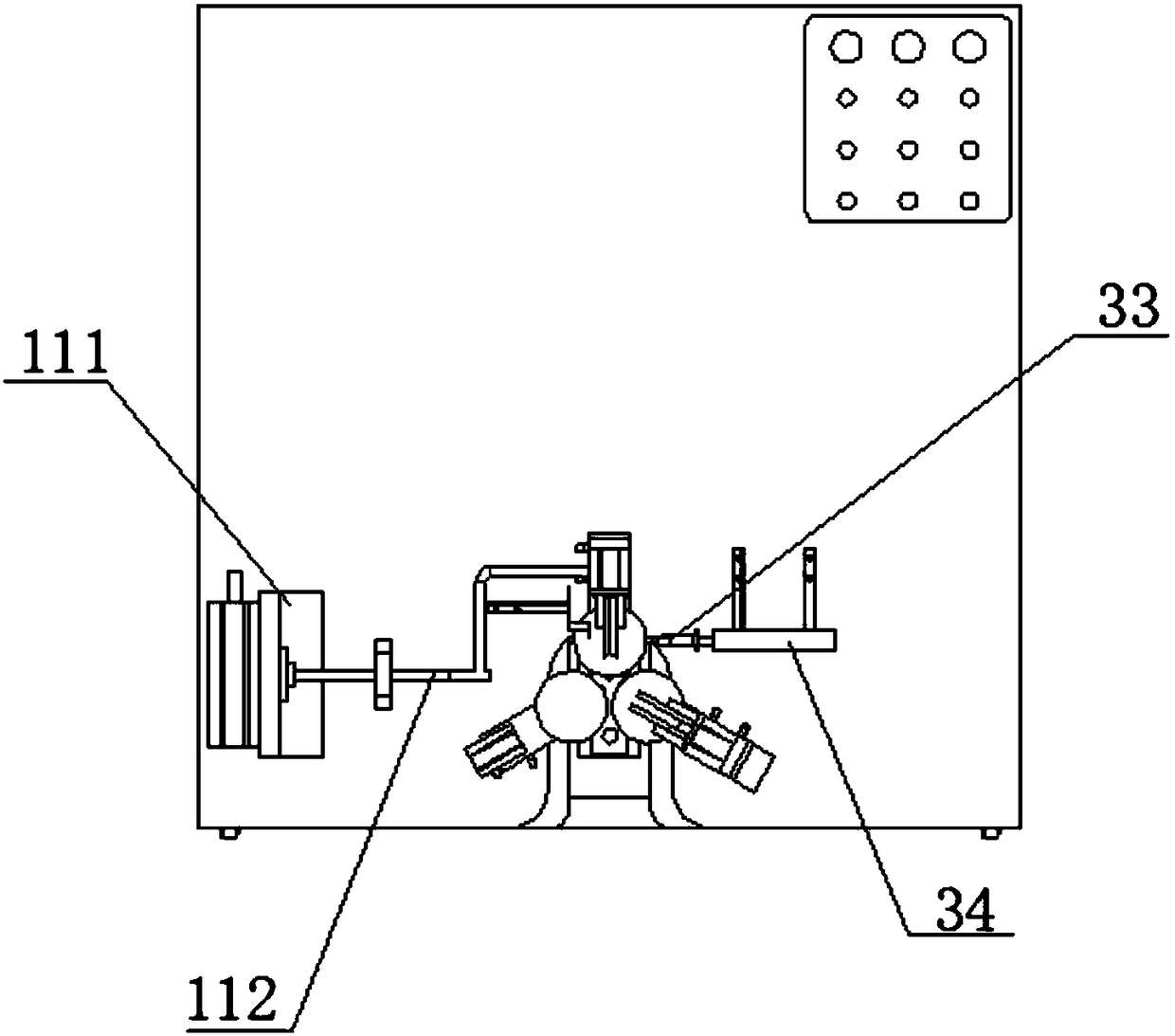

[0054] Figure 4 A structural schematic diagram of a ring-shaped inductor winding machine provided in an embodiment of the present invention at a viewing angle, Figure 5 For a schematic view of the structure of the ring-shaped inductor winding machine provided by the embodiment of the present invention, please refer to Figure 3-5 As shown, this embodiment has an overall structure similar to that of Embodiment 1, the difference is that this embodiment provides a specific structure of a ring-shaped inductor winding machine on the basis of Embodiment 1.

[0055] In this embodiment, the first clamping structure 12 includes a first finger cylinder for clamping the inductor wire, and a fifth driving structure for driving the first finger cylinder, and the second clamping structure 22 includes The second finger cylinder for clamping the inductance wire is used to drive the sixth drive structure of the second finger cylinder. The first drive structure 11 includes a rotary cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com