A heat dissipation structure of a COB type LED packaging unit

A technology of LED packaging and heat dissipation structure, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reduced service life, low heat dissipation efficiency, slow speed, etc., to increase heat dissipation effect, prolong service life, and fast exchange rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

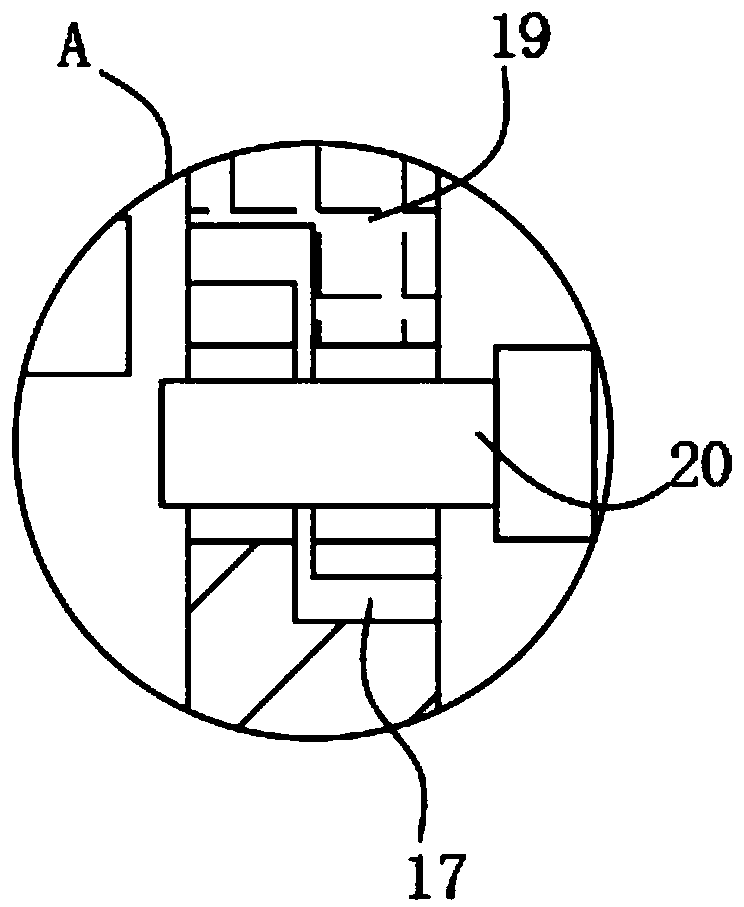

[0018] refer to Figure 1-2 , a heat dissipation structure of a COB-type LED packaging unit, including a housing 1, the housing 1 is a hollow structure, the side wall of the housing 1 away from the drive motor 3 is provided with an opening 17, and the side wall of the opening 17 is rotated by a second rotating shaft 18 Be connected with baffle plate 19, the side wall of baffle plate 19 is provided with fixed pin 20, and fixed pin 20 is set through the side wall of baffle plate 19 and opening 17, when needs detection and maintenance, can pull out fixed pin 20, open baffle plate plate 19, you can clearly observe the internal situation from the opening 17 and carry out maintenance. After the maintenance is completed, cover the baffle plate 19 and insert the fixing pin 20, so that the baffle plate 19 can be fixed and will not swing easily;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com