A kind of preparation method of loofah base cation exchange fiber

An ion-exchange fiber and loofah-based cation technology, which is applied in the direction of cation exchange materials, ion exchange water/sewage treatment, etc., can solve the problems of difficult large-scale production, high grafting cost, and low grafting rate, and achieve exchange Fast rate, simple desorption, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

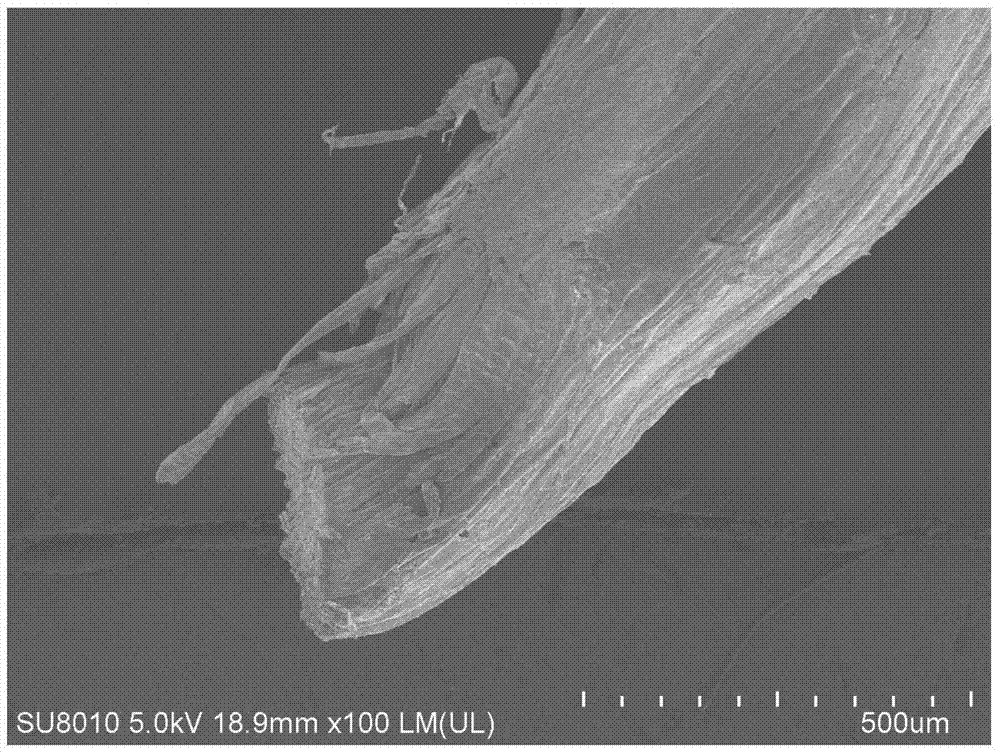

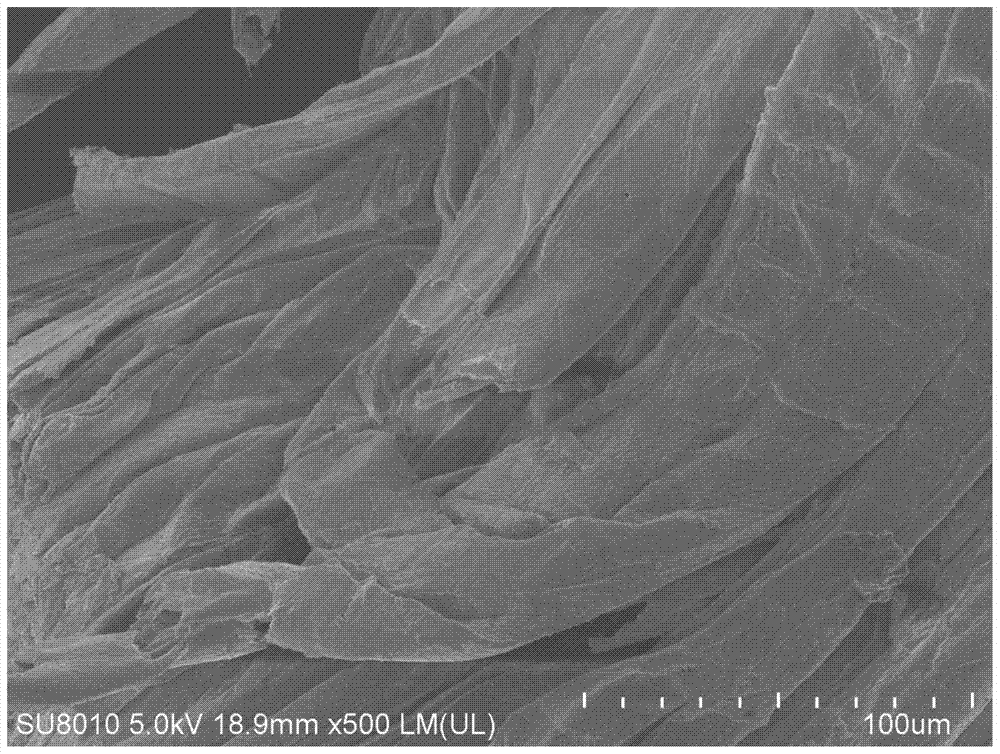

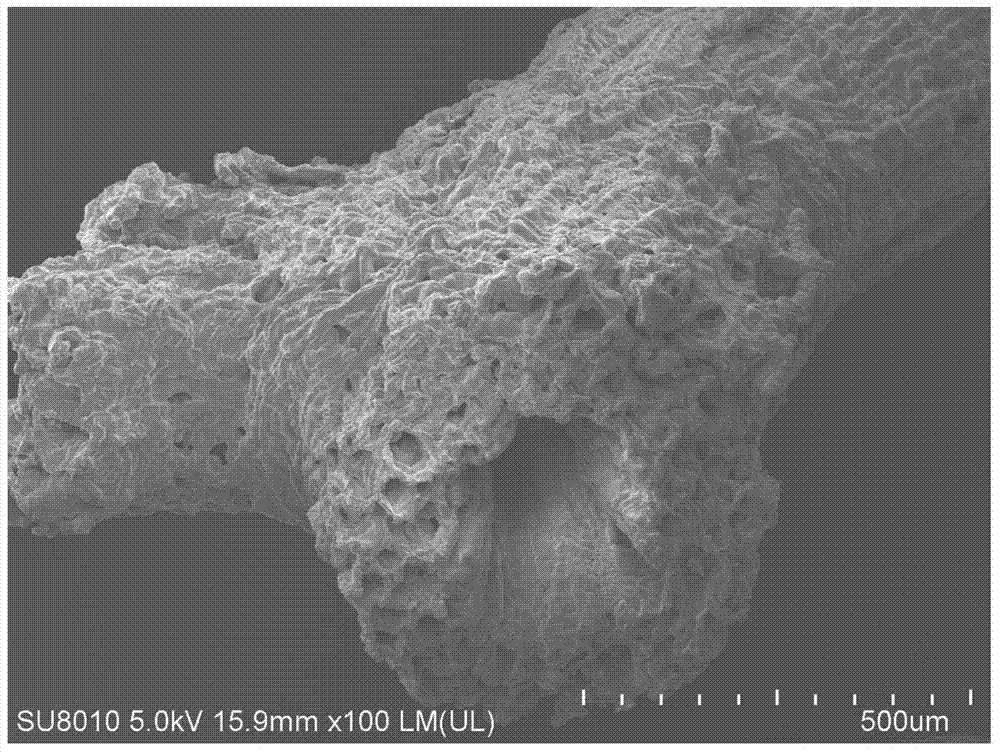

Image

Examples

Embodiment 1

[0030] Firstly, the naturally grown loofah is air-dried, then cut, the skin and the loofah seeds inside the pores are removed, and the loofah is cut into blocks. Put the lump loofah in boiling water and boil for 20 minutes, then wash with distilled water to remove surface impurities, put it in an oven to dry at 40°C, and set aside. Get a certain quality of the above block loofah and put it into a petri dish, add 10ml of photosensitizer / ethanol solution with a concentration of 1.0wt%, put it into a fume hood and soak it in the dark; Transfer to a 40ml quartz glass test tube, add 20ml of acrylic acid / water solution with a concentration of 10.0wt%, seal the test tube with a rubber stopper, and react for 7h under a UV lamp with a power of 100W. After the reaction is completed, wash the remaining acrylic acid monomer on the surface with boiling water , and extracted with acetone in a Soxhlet extractor to wash off short-chain self-polymers, weighed and calculated after drying, and o...

Embodiment 2

[0033] Firstly, the naturally grown loofah is air-dried, then cut, the skin and the loofah seeds inside the pores are removed, and the loofah is cut into blocks. Put the lump loofah in boiling water and boil for 20 minutes, then wash with distilled water to remove surface impurities, put it in an oven to dry at 40°C, and set aside. Get a certain quality of the above block loofah and put it into a petri dish, add 10ml of photosensitizer / methanol solution with a concentration of 0.5wt%, put it into a fume hood and soak it in the dark; Transfer to a 40ml quartz glass test tube, add 20ml of acrylic acid / water solution with a concentration of 15.0wt%, seal the test tube with a rubber stopper, and react for 48h under a 7W UV lamp. After the reaction is completed, wash the remaining acrylic acid monomer on the surface with boiling water , and extracted with acetone in a Soxhlet extractor to wash away short-chain self-polymers, weighed and calculated after drying, a loofah-based catio...

Embodiment 3

[0036]Firstly, the naturally grown loofah is air-dried, then cut, the skin and the loofah seeds inside the pores are removed, and the loofah is cut into blocks. Put the lump loofah in boiling water and boil for 20 minutes, then wash with distilled water to remove surface impurities, put it in an oven to dry at 40°C, and set aside. Get the above-mentioned block loofah of a certain quality and put it into a petri dish, add 10ml of concentration and be 0.2wt% photosensitizer / isopropanol solution, put into a fume hood and soak in the dark; after the photosensitizer solution is naturally volatilized completely, Transfer the loofah to a 40ml quartz glass test tube, add 20ml of acrylic acid / water solution with a concentration of 20.0wt%, seal the test tube with a rubber stopper, and react for 7 hours under a 100W ultraviolet lamp. After the reaction is completed, wash the remaining acrylic acid on the surface with boiling water monomer, and extracted with acetone in a Soxhlet extract...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com