A kind of preparation method of high flux composite forward osmosis membrane

A forward osmosis membrane, high-flux technology, applied in the direction of semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problem of unfavorable water and solvent rapid exchange, the inability to form an open bottom surface structure, and low forward osmosis flux to achieve the effects of reducing internal concentration polarization, increasing water flux, and reducing structural parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1: A stainless steel microporous membrane was used as the substrate.

[0047]Preparation method: The glass plate was replaced with a stainless steel microporous membrane, and the remaining steps were the same as in Comparative Example 1. The prepared high-performance composite forward osmosis membrane was fully cleaned with deionized water and stored in a 0.1% sodium bisulfite solution.

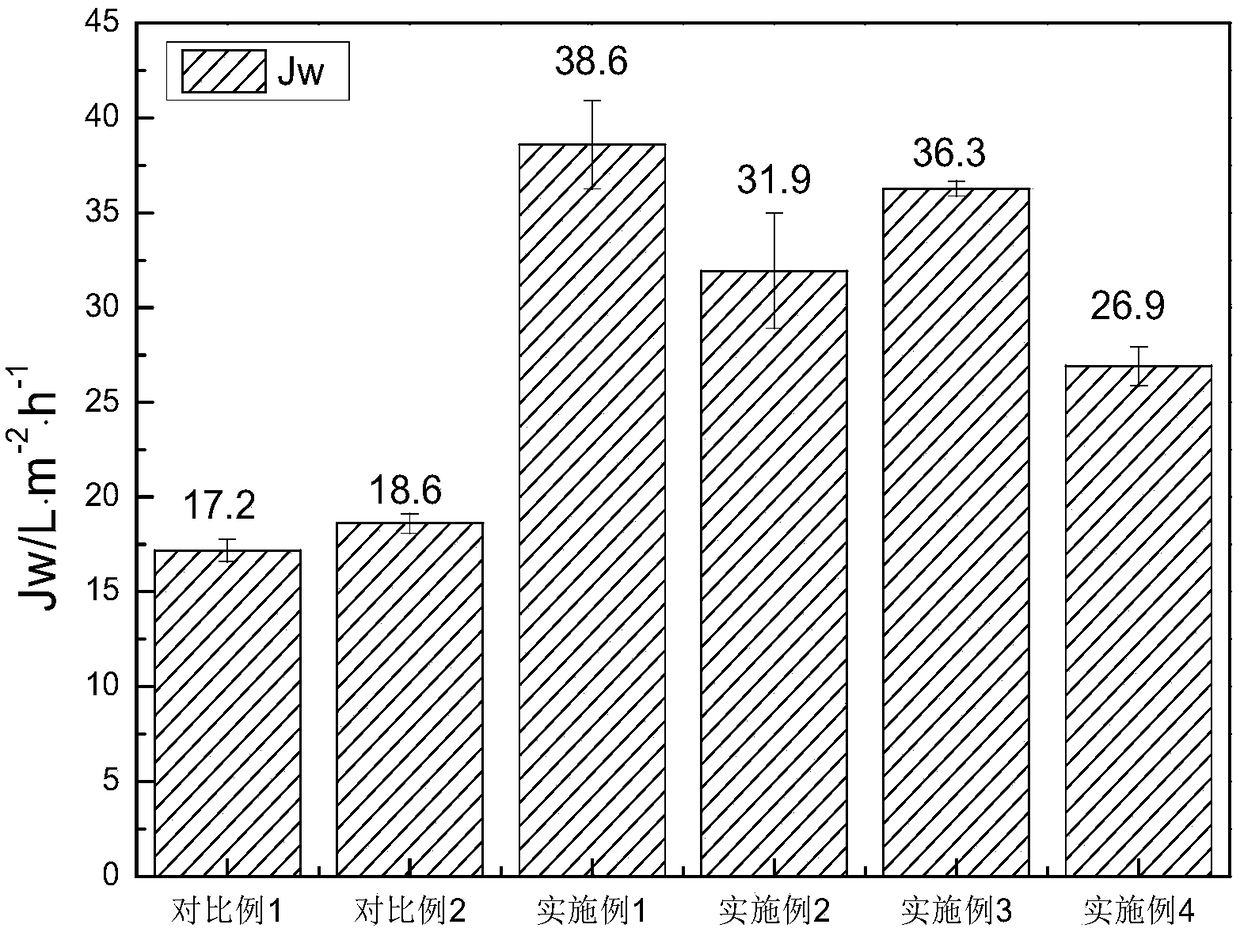

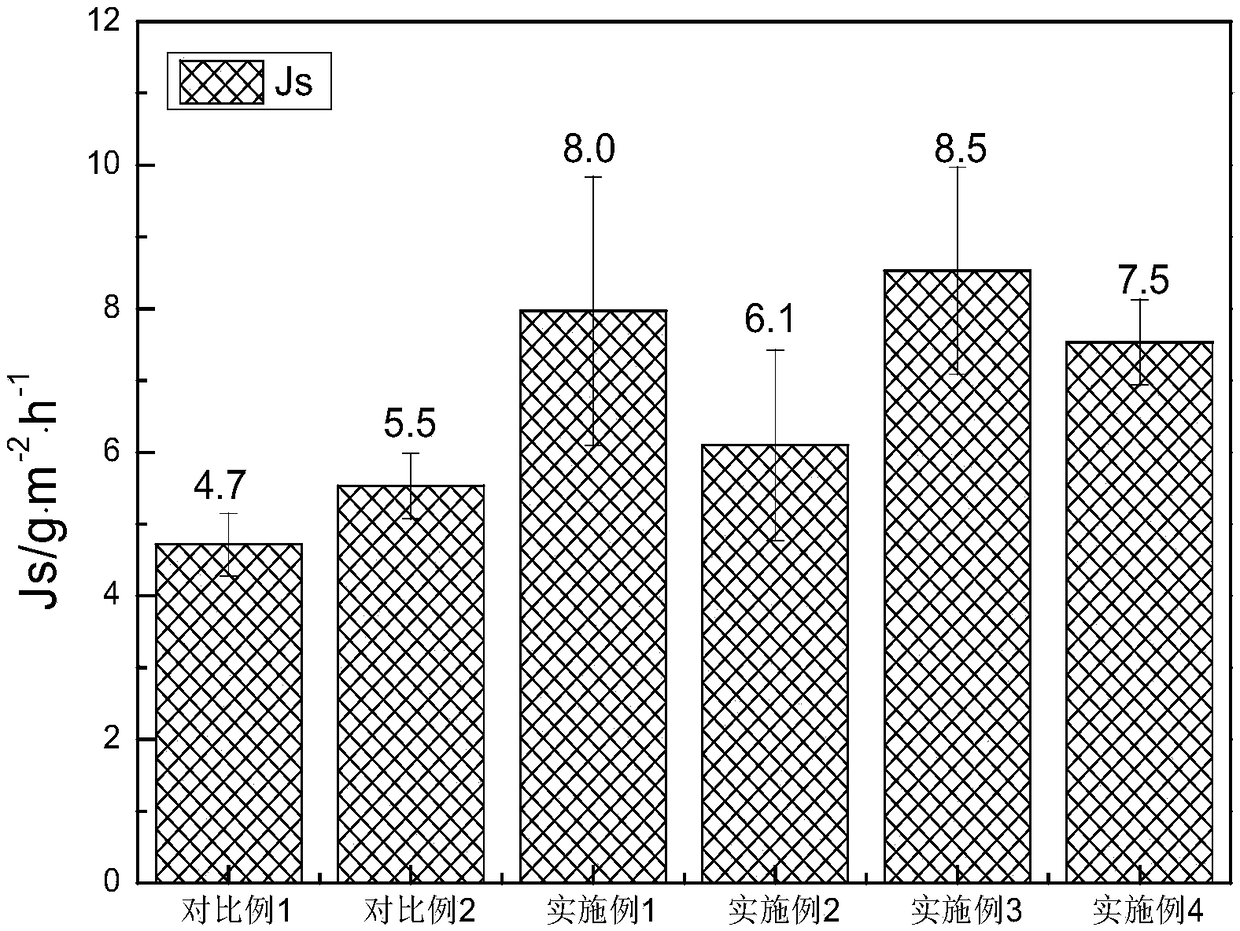

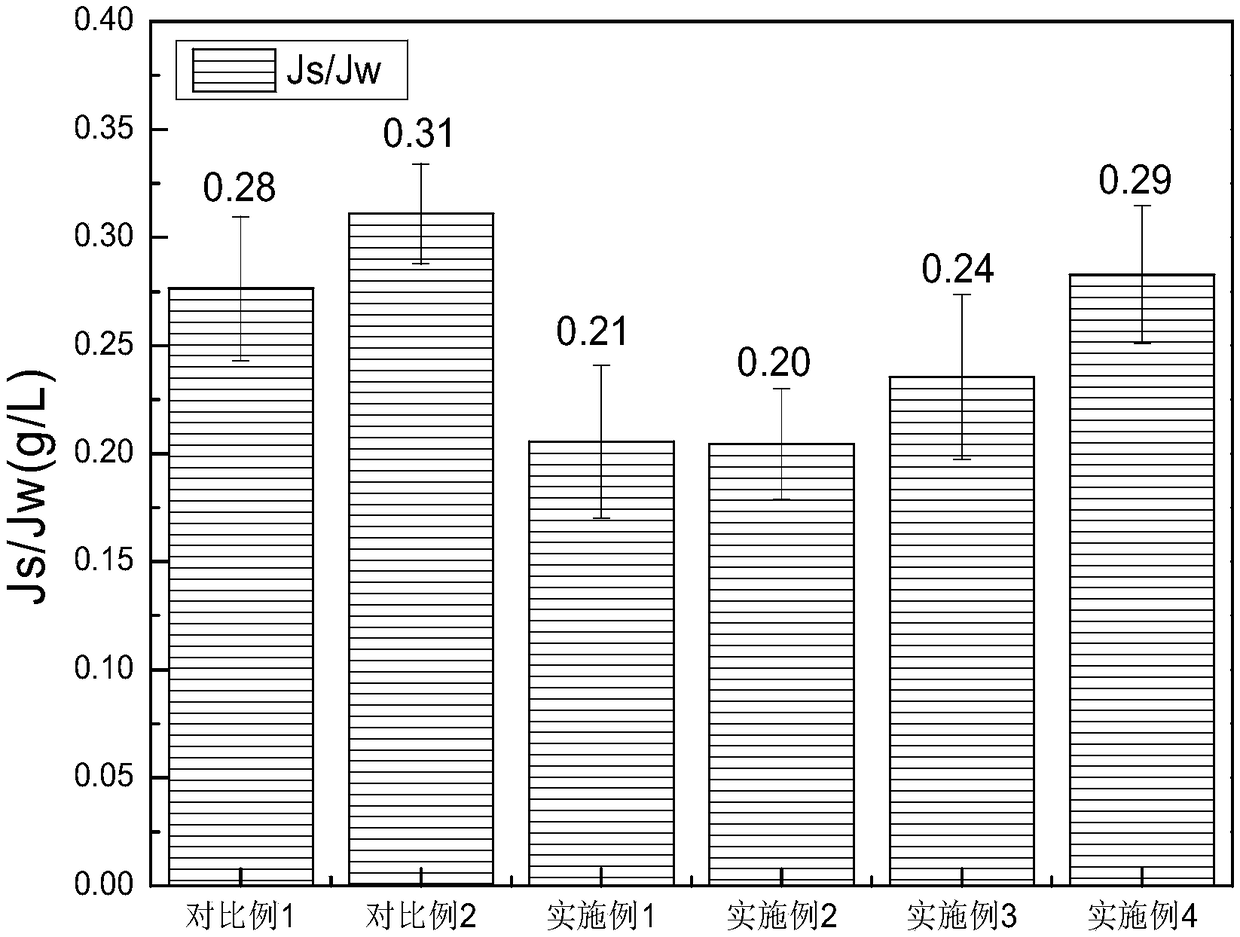

[0048] Performance: Using 1M NaCl and deionized water as the drawing liquid and raw material liquid, the forward osmosis water flux is 38.6±2.3LMH, the reverse salt flux is 8.0±1.9gMH, and the brine ratio is 0.21g / L.

[0049] Structure: The membrane is composed of two parts, a porous support layer and a dense separation layer. The bottom surface structure is completely open. The sponge layer in the support layer is extremely thin, and the finger-shaped pores almost run through the entire section of the membrane. The structural parameter is 172.5 μm.

Embodiment 2

[0050] Example 2: Using a porous frit as a substrate.

[0051] Preparation method: replace the glass plate with a porous sieve plate, and the remaining steps are the same as in Comparative Example 1. The prepared high-performance composite forward osmosis membrane is fully cleaned with deionized water and stored in a 0.1% sodium bisulfite solution.

[0052] Performance: Using 1M NaCl and deionized water as the drawing liquid and raw material liquid, the forward osmosis water flux is 31.9±3.0LMH, the reverse salt flux is 6.1±1.3gMH, and the brine ratio is 0.20g / L.

[0053] Structure: The membrane is composed of a porous support layer and a dense separation layer. The bottom surface has a high open porosity. The spongy layer in the support layer is extremely thin. The finger-shaped pores almost run through the entire section of the membrane. The structural parameter is 235.8 μm.

Embodiment 3

[0054] Example 3: Using a ceramic microporous membrane as a substrate.

[0055] Preparation method: The glass plate was replaced with a ceramic microporous membrane, and the remaining steps were the same as in Comparative Example 1. The prepared high-performance composite forward osmosis membrane was fully cleaned with deionized water and stored in a 0.1% sodium bisulfite solution.

[0056] Performance: Using 1M NaCl and deionized water as the drawing liquid and raw material liquid, the forward osmosis water flux is 36.3±0.4LMH, the reverse salt flux is 8.5±1.4gMH, and the brine ratio is 0.24g / L.

[0057] Structure: The membrane is composed of a porous support layer and a dense separation layer. The bottom surface is a completely open structure. The support layer is composed of an extremely thin sponge-like layer and a finger-like pore layer with small tortuosity. The overall thickness of the membrane is about 100μm. The structural parameter is 190.7 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com