Same-direction-engaged Lelo triangular rotor pump

A triangular, rotor pump technology, used in rotary piston pumps, pumps, rotary piston machines, etc., can solve problems such as limiting the application of gear pumps, and achieve the effect of shortening the pump oil route, reducing friction loss, and simple rotor structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

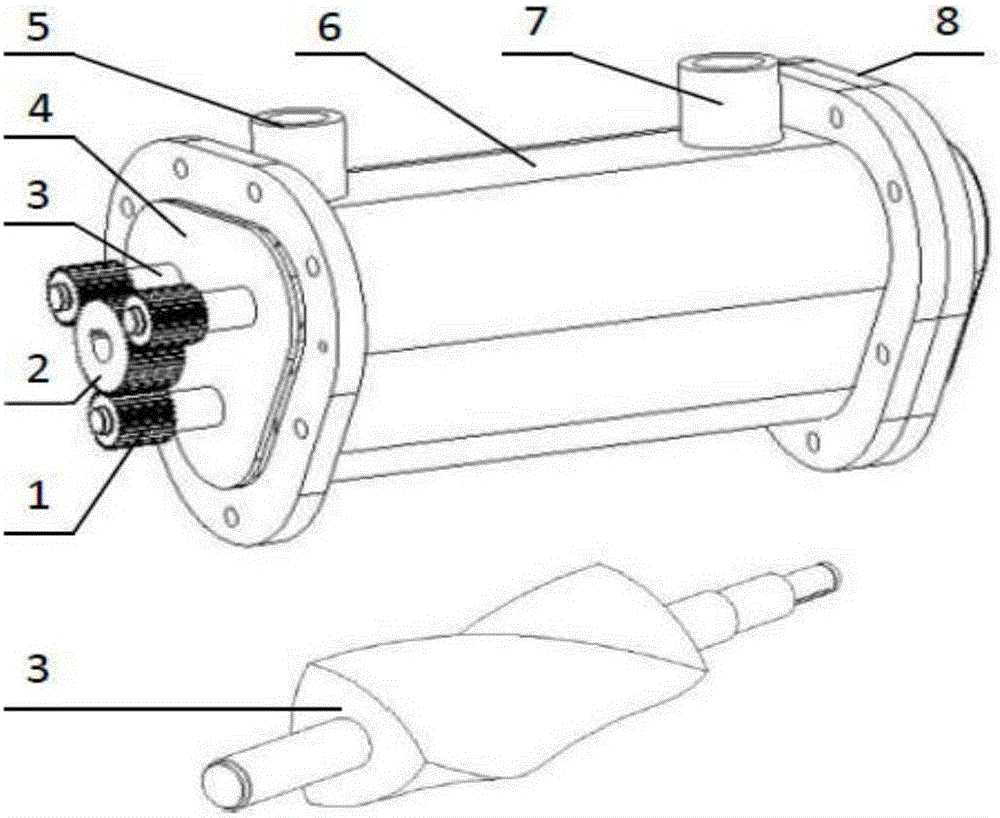

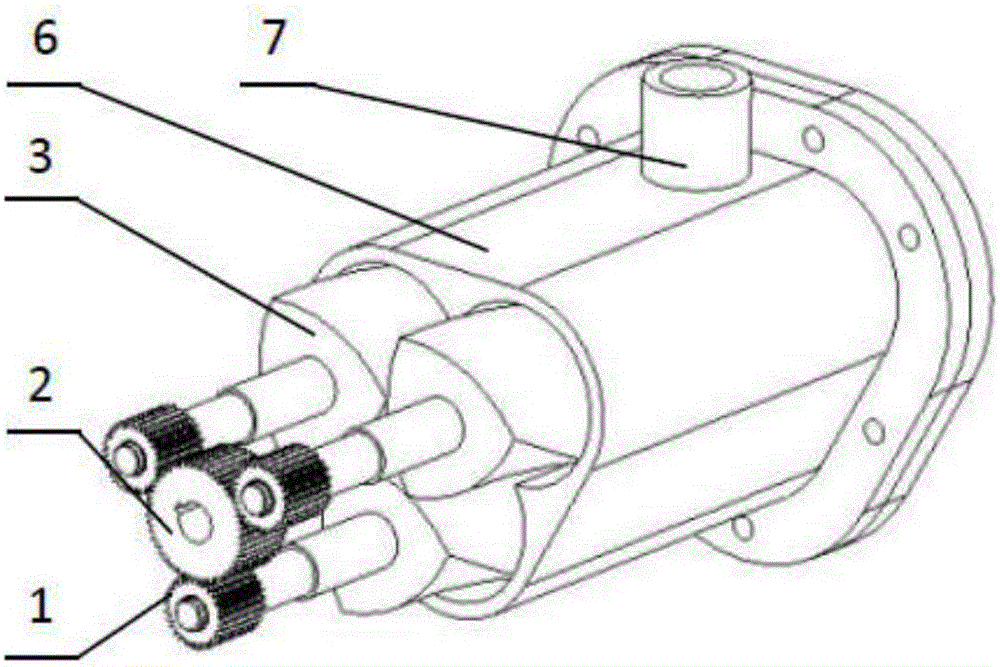

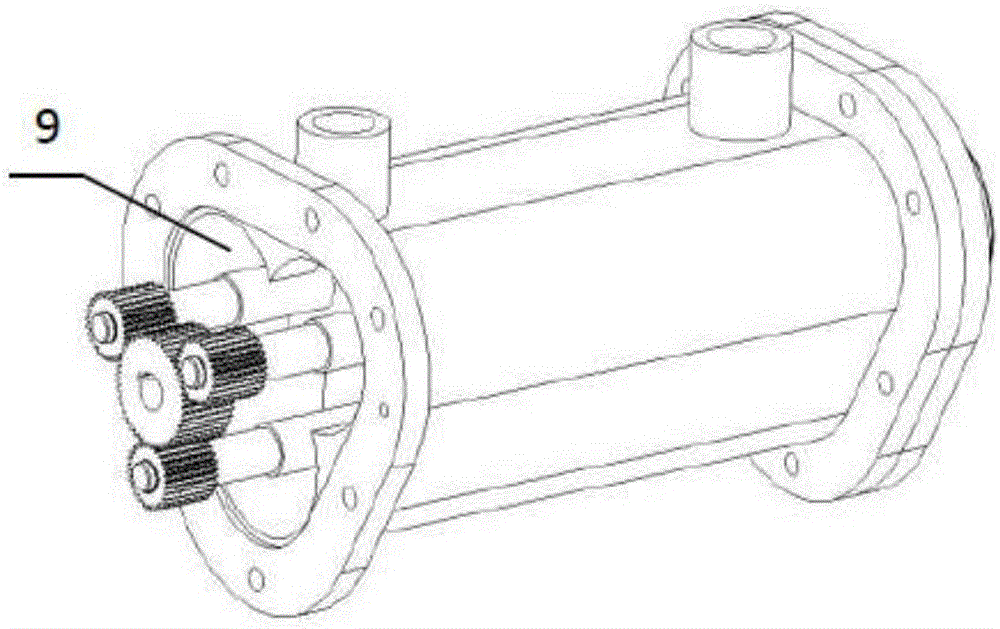

[0020] This embodiment is a co-meshing Lello triangular rotor pump.

[0021] refer to Figure 1 to Figure 6 , the present embodiment Lello triangular rotor pump consists of driven gear 1, driving gear 2, Lello triangular rotor 3, front pump cover 4, oil outlet 5, pump body 6, oil inlet 7, rear pump cover 8, exhaust Oil cavity 9, oil suction cavity 10 are formed. The three Lello triangular rotors 3 are installed in parallel inside the pump body 5, and the assembly position relationship is as follows: Figure 6 As shown, the assembly position of the rotor 3 satisfies △A 1 B 1 C 1 ≌△A 2 B 2 C 2 ≌△A 3 B 3 C 3 ≌△O 1 o 2 o 3 , and the above four triangles are all equilateral triangles, O 1 , O 2 , O 3 △A 1 B 1 C 1 、△A 2 B 2 C 2 、△A 3 B 3 C 3 center of gravity, A 1 B 1 ∥A 2 B 2 ∥A 3 B 3 . The rotating shaft of the rotor 3 is fixedly connected with three driven gears 1, and the driving gear 2 and the driven gear 1 are installed on the outside of the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com