Dedicated weeding device for apple orchard

A technology for weeding equipment and apple orchards, applied in the fields of application, soil preparation machinery, agricultural machinery and implements, etc., can solve the problems of chemical weeding side effects, increase production costs, time-consuming and laborious, etc., to reduce repetition and dullness, and increase work. Efficiency, the effect of improving weeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

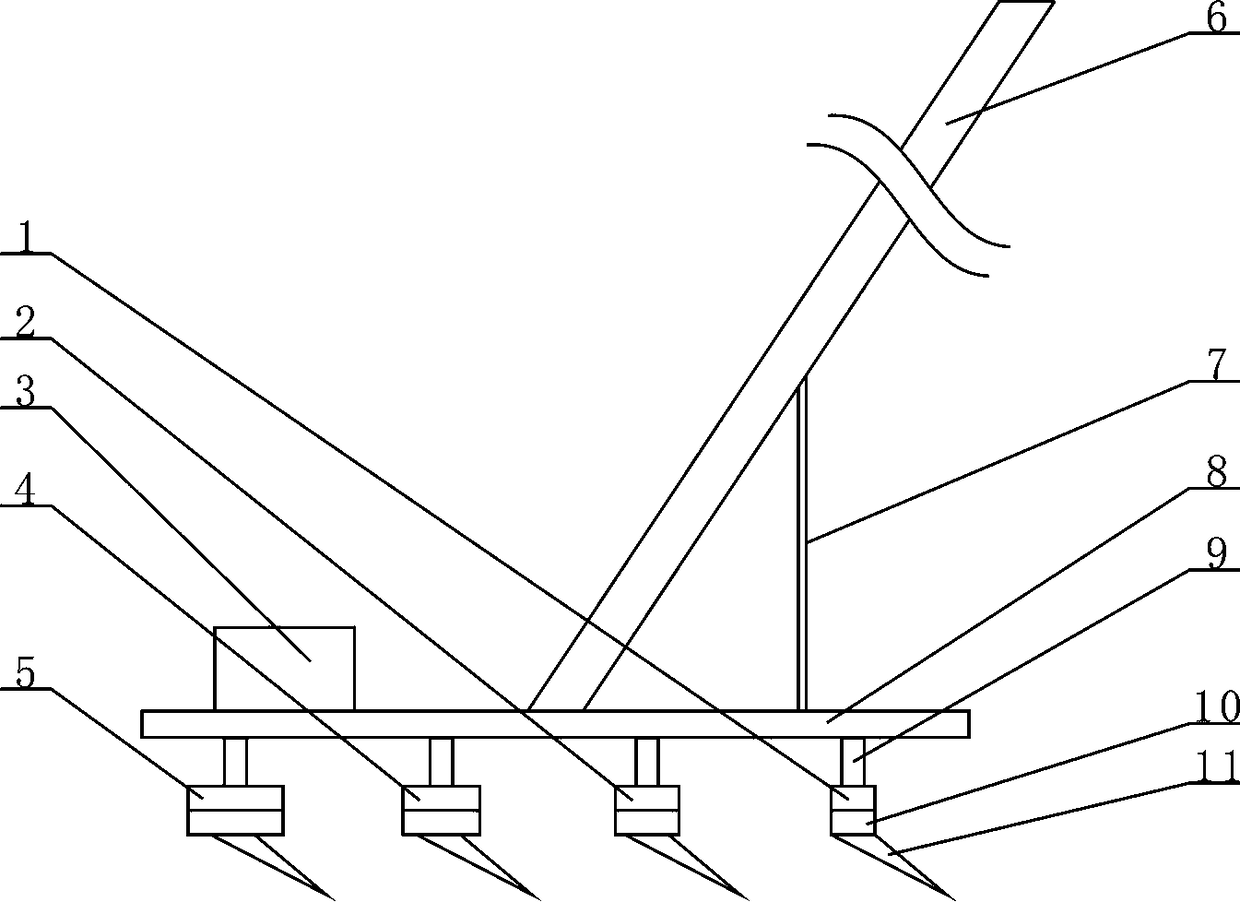

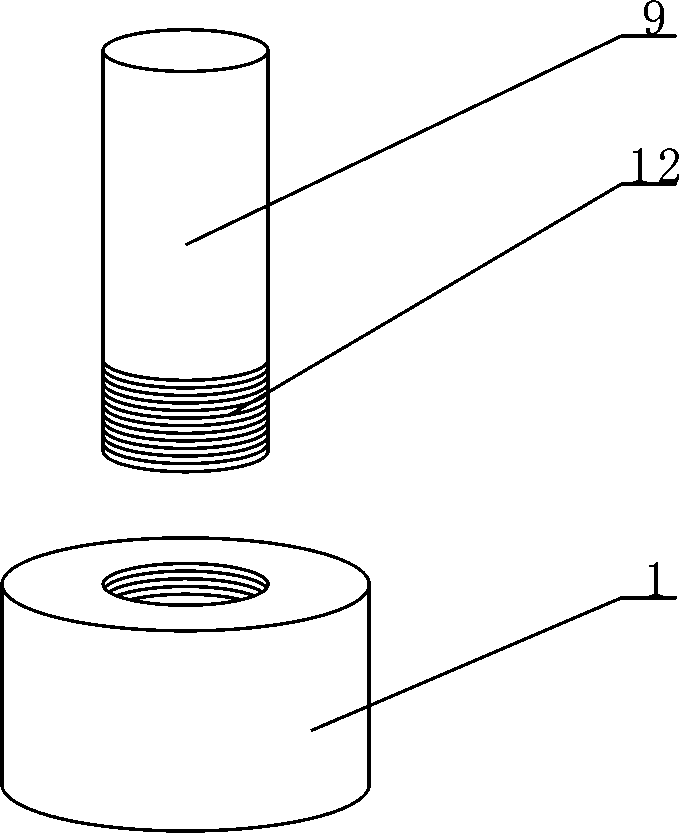

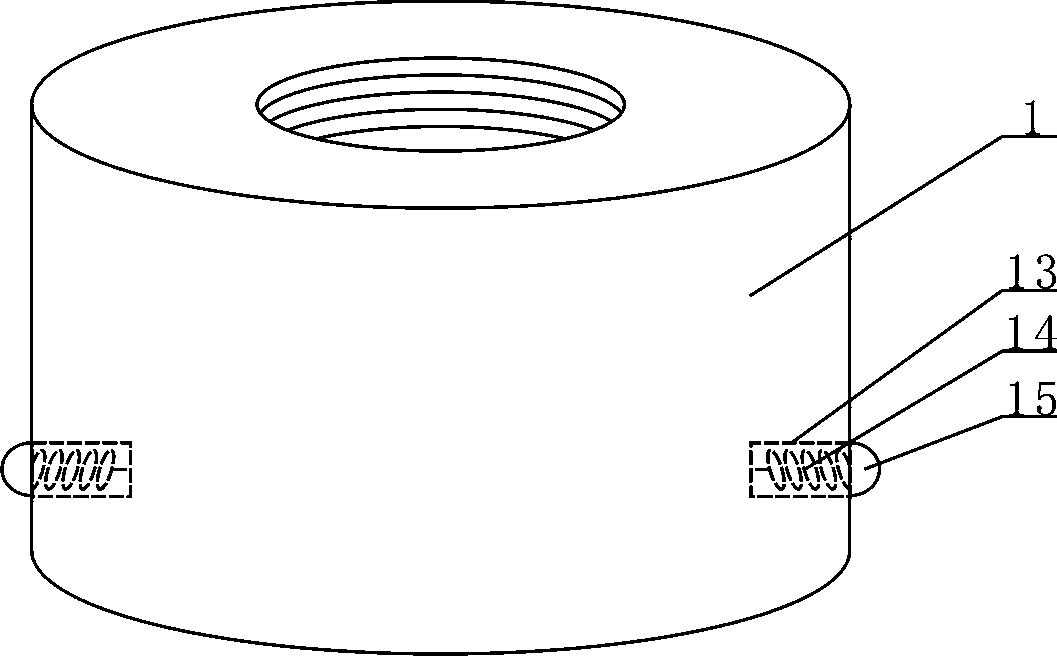

[0032] A kind of special weeding equipment for apple orchard described in embodiment 1, when in use, first set pressure block 3 and operating rod 6 on support plate 8, pressure block 3 is fixedly connected with support plate 8, the bottom of operating rod 6 and The center of the top surface of the support plate 8 is connected by a buckle, so that the operating rod 6 can change the angle on the support plate 8 and move. , the first connecting ring 18 is fastened to the second connecting ring 19, the second connecting ring 19 is connected to the upper rod 20, the upper rod 20 is connected to the lower rod 27 through the clamping post 22 at the bottom, and the clamping post 22 is placed on the lower rod 27 Between the first block 24 and the second block 26 on the top surface, so that the first jack 23, the second jack 25 and the through hole 21 are located on the same straight line, and the pins are sequentially inserted into the first jack 23, Through hole 21 and the second sock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com