Thifensulfuron methyl and clodinafop-propargyl water dispersible granule and preparation method and application thereof

A technology of thifensulfuron-methyl and thifensulfuron-methyl technical, which is applied in the field of pesticides, can solve the problems of dust and organic solvent environmental pollution, application restrictions, narrow weeding spectrum, etc., and achieve the goals of wide application area, small dosage and improved drug efficacy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

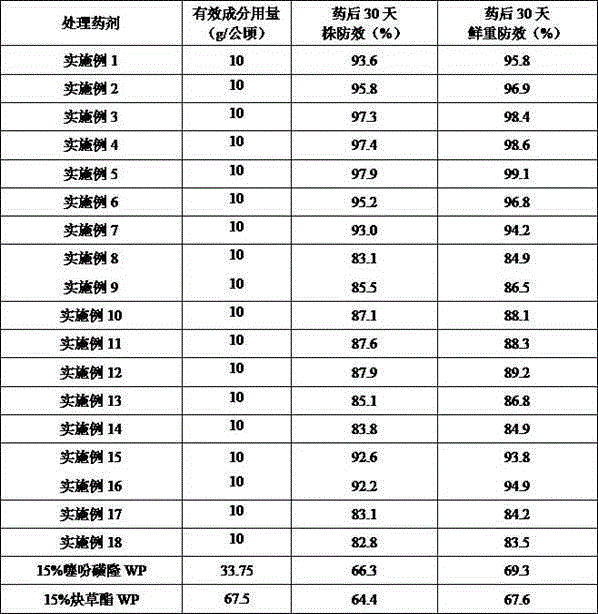

Examples

Embodiment 120

[0022] Embodiment 120% thifensulfuron-clodinafop-propargyl water-dispersible granules

[0023] The formula is: thifensulfuron-methyl 4%, clodinafop-propargyl 16%, polycarboxylate sodium salt 4%, calcium lignosulfonate 2%, sodium lauryl sulfate 1.5%, sodium lignosulfonate 1.5%, ethylene glycol Disodium amine tetraacetate 2%, ammonium sulfate 4.5%, urea 3%, white carbon black 5%, corn starch added to 100%.

[0024] The preparation method is as follows: mix the thifensulfuron-methyl original drug, clodinafop-propargyl original drug, dispersant, wetting agent, chelating agent, disintegrant, adsorbent, and filler in a mixer evenly, and pulverize it to the particle size through a jet mill. After 600-800 mesh, mix evenly, then add water with 20-30% of the total mass of the material for kneading, after kneading, carry out extrusion granulation, and dry the obtained granules at 40-50°C to make water-dispersible granules .

Embodiment 244

[0025] Embodiment 244% thifensulfuron-clodinafop-propargyl water-dispersible granules

[0026] The formula is: thifensulfuron-methyl 11%, clodinafop-propargyl 33%, polycarboxylate sodium salt 4%, calcium lignosulfonate 2%, sodium lauryl sulfate 1.5%, sodium lignosulfonate 1.5%, ethylene glycol Disodium amine tetraacetate 2%, ammonium sulfate 4.5%, urea 3%, white carbon black 5%, corn starch added to 100%.

[0027] The preparation method is the same as in Example 1.

Embodiment 330

[0028] Embodiment 330% thifensulfuron-clodinafop-propargyl water-dispersible granules

[0029] The formula is: thifensulfuron-methyl 10%, clodinafop-propargyl 20%, polycarboxylate sodium salt 4%, calcium lignosulfonate 2%, sodium lauryl sulfate 1.5%, sodium lignosulfonate 1.5%, ethylene glycol Disodium amine tetraacetate 2%, ammonium sulfate 4.5%, urea 3%, white carbon black 5%, corn starch added to 100%.

[0030] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com