High-efficiency weeding robot

A robot and high-efficiency technology, applied in the direction of land preparation machinery, guiding agricultural machinery, equipment for weed elimination, etc., can solve the problems that it is not easy to identify weeds, and the weeds in the field have not been solved well, so as to solve the problem of removal and work The effect of high speed and lightening load

Inactive Publication Date: 2011-01-05

NANJING FORESTRY UNIV

View PDF1 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, as can be seen from the previous analysis, it is not easy to identify weeds, so the removal of weeds in the industry has always been an unsolved problem.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

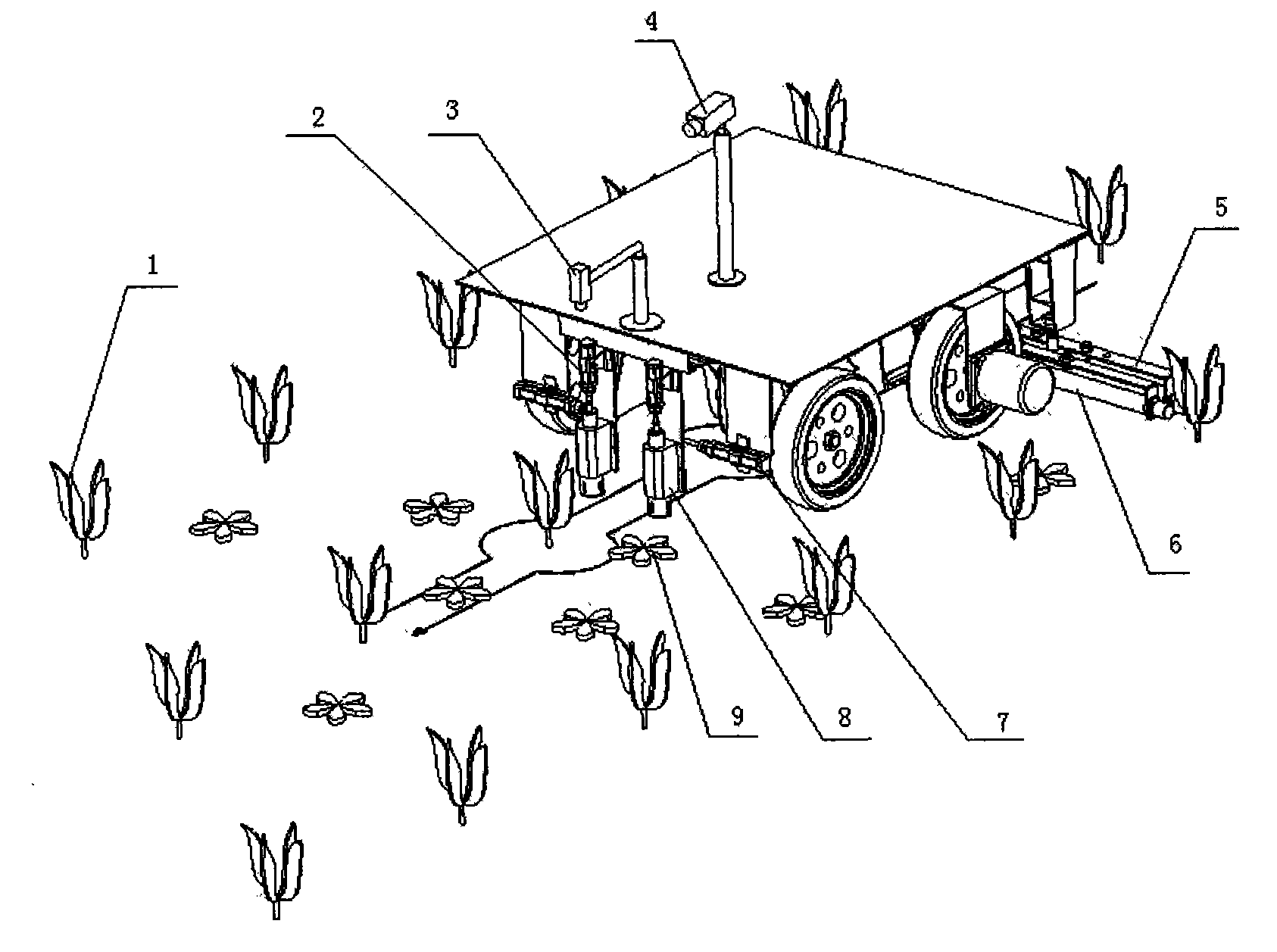

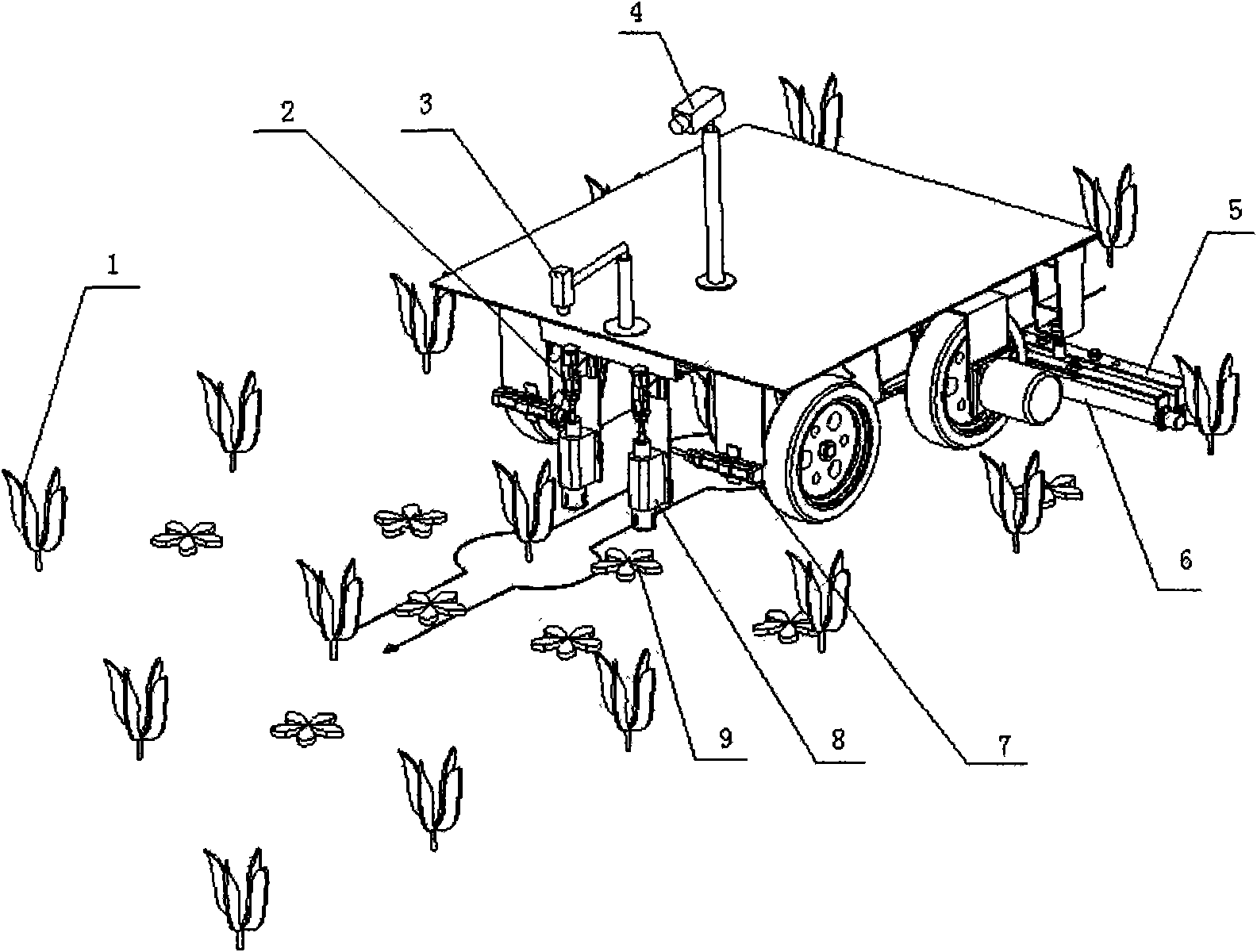

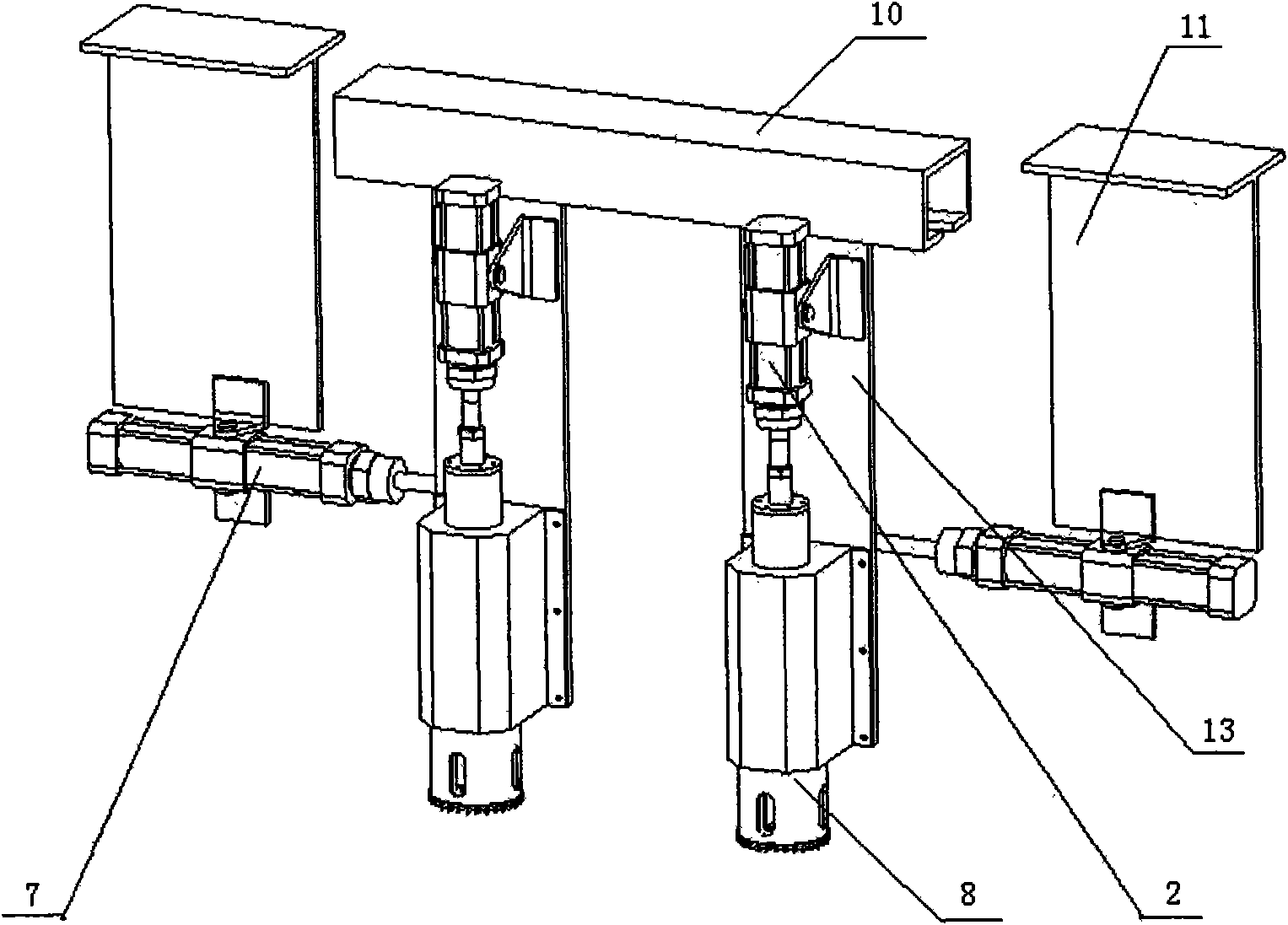

The invention relates to a high-efficiency weeding robot which belongs to the technical field of agricultural machinery application. The robot comprises an automatic navigation and weed identification camera head and a control system, wherein a weeding device comprises an interline cutting and smearing weeding mechanism arranged below a trolley, and an inline weeding mechanism; the cylinder bodies of a left horizontal cylinder and a right horizontal cylinder of the inline weeding mechanism are respectively arranged at the bottom of the trolley; horizontal piston rods of the left horizontal cylinder and the right horizontal cylinder are respectively and fixedly connected with installment frames of a left vertical cylinder and a right vertical cylinder; the upper ends of the installment frames of the left vertical cylinder and the right vertical cylinder are installed in horizontal rails on the trolley to form a moving pair; the cylinders of the left vertical cylinder and the right vertical cylinder are respectively installed on the installment frames of the left vertical cylinder and the right vertical cylinder; and the lower ends of vertical pistons of the left vertical cylinder and the right vertical cylinder are respectively connected with a left end effector and a right end effector the bottoms of which are provided with electric circular saws. The invention can remove weeds in lines and among lines with high working speed and high weeding efficiency, thereby radically solving the difficulty of removing weeds in lines.

Description

Efficient weeding robot technical field The invention relates to an efficient weeding robot, in particular to an intelligent weeding robot capable of simultaneously removing weeds in and between rows of crops, and belongs to the technical field of agricultural machinery applications. Background technique The weeding robot, as the name suggests, is used to automatically remove weeds in the field during the seedling stage of the crops. Suitable for row-grown crops such as corn, cotton, and soybeans. In such farmland, weeds can be divided into "interrow weeds" and "intrarow weeds" according to their spatial distribution characteristics. The so-called "interrow weeds" refer to weeds that grow between two crop rows; while "intrarow weeds" refer to weeds that grow within a crop row, that is, weeds that grow on the same row as the crop. At present, chemical weeding in farmland mainly adopts spraying method. It can be applied by sprayer or by aerial application. The advantage...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): A01M21/00A01M21/02A01M21/04

CPCA01B39/18A01B69/001A01B69/008A01M21/02

Inventor 陈勇孙曼丽

Owner NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com