Integrated rotary type tomato pomace drying device

A drying device and tomato pomace technology, applied in application, food processing, food science and other directions, can solve the problems of excessive tomato pomace throwing, excessive energy consumption, poor drying effect, etc., to improve drying effect and reduce coal consumption , Improve the effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

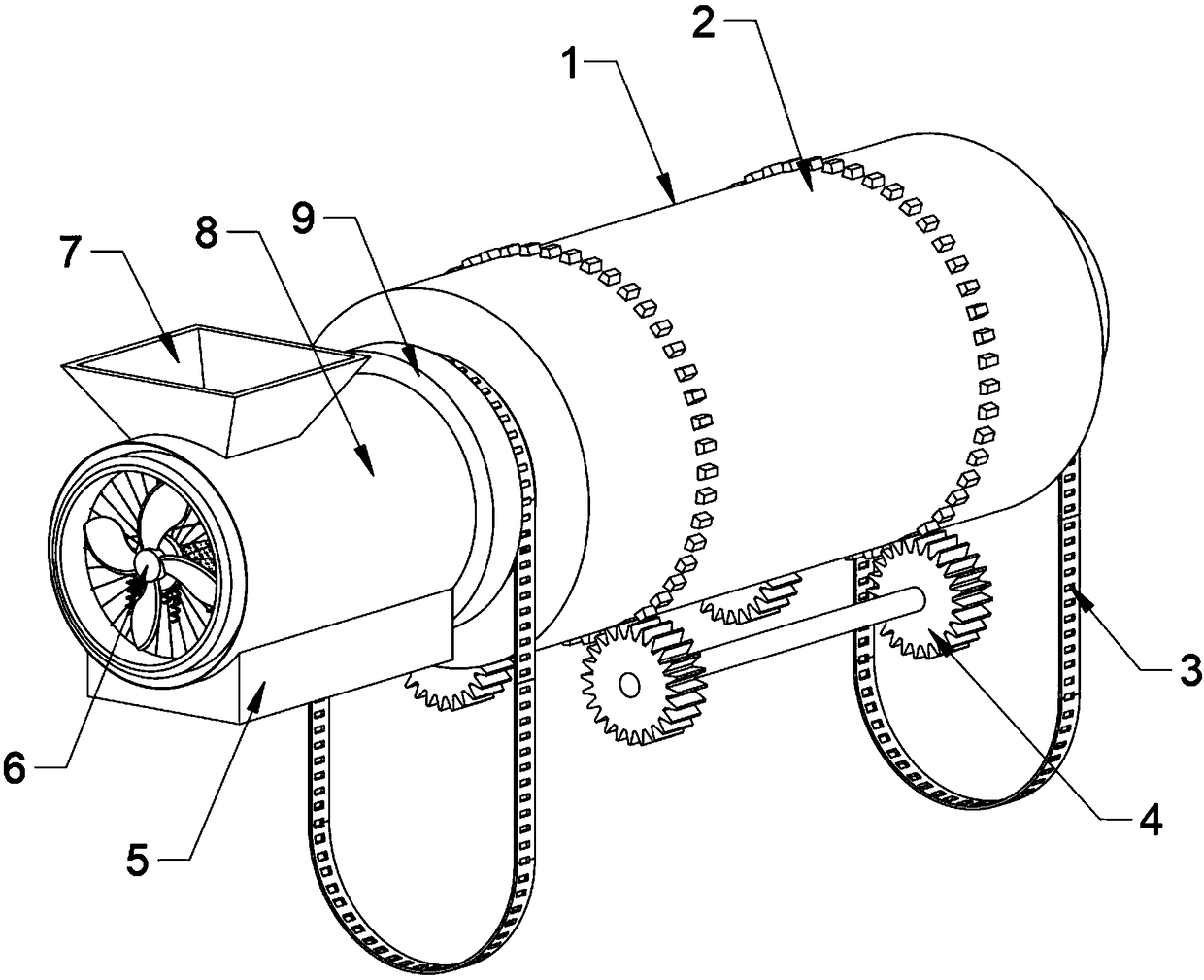

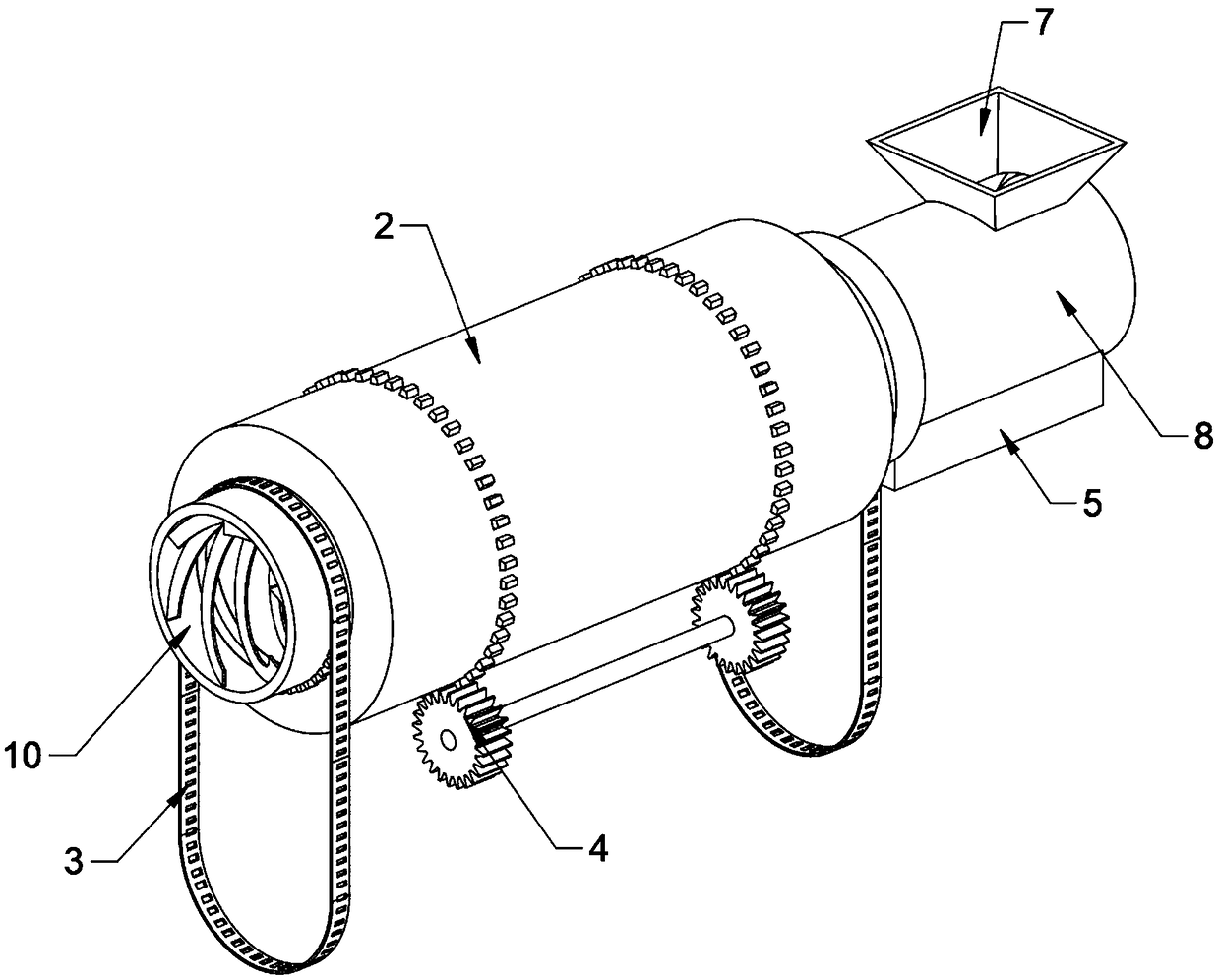

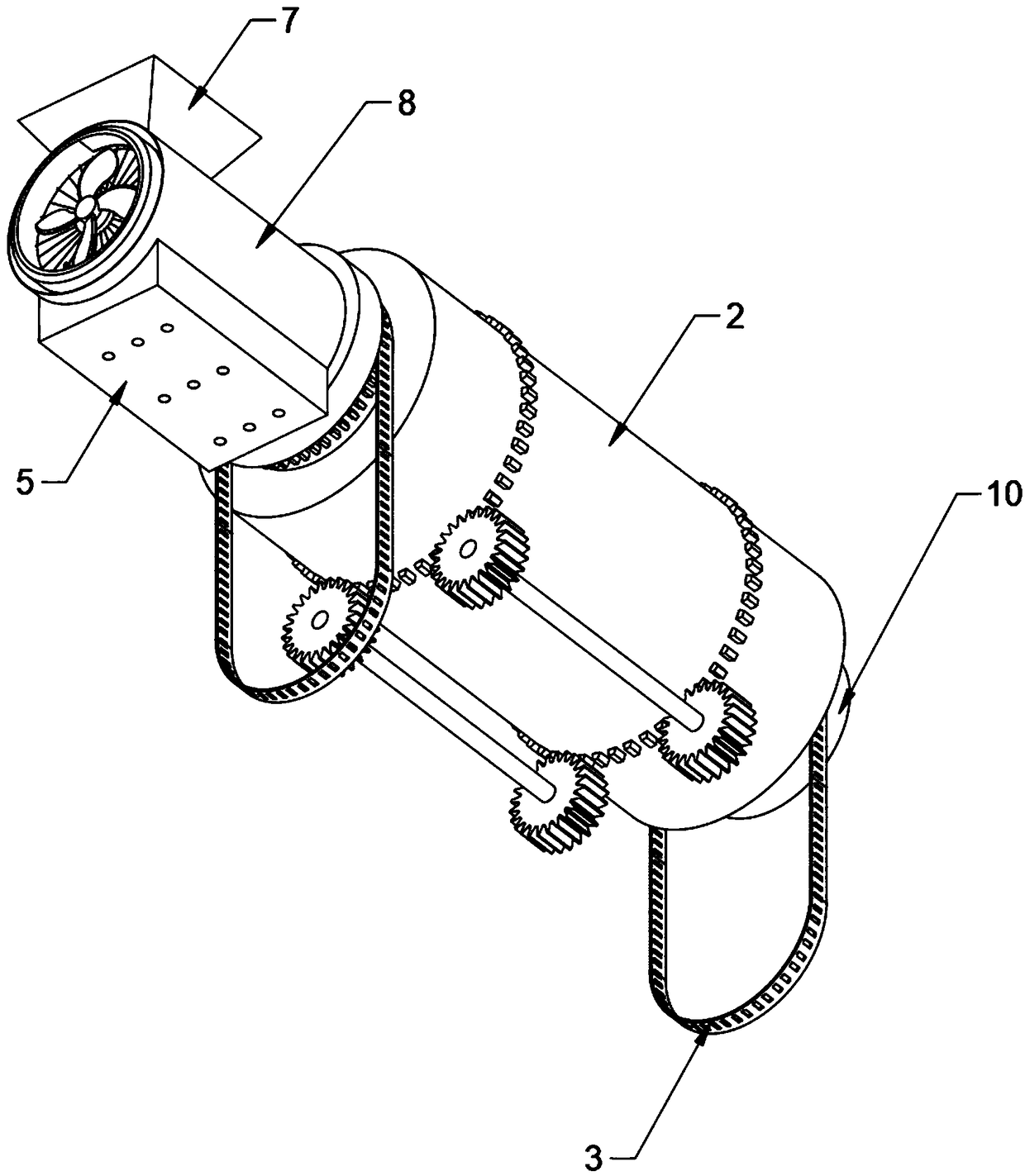

[0038] as attached figure 1 to attach Figure 8 Shown:

[0039] The present invention provides an integrated rotary tomato pomace drying device, which includes: a device body 1, a heat preservation cylinder 2, a driving chain 3, a supporting rotating gear set 4, a vibrator 5, a vibrating drying plate 501, and a juice discharge hole 502, hot air input fan 6, feeding port 7, vibrating drying cylinder 8, rotating bearing 9, drying cylinder 10, dispersing drying cylinder 1001, scattering lifting plate 1001a, uniform output drying cylinder 1002 and spiral output blade 1002a The front side of the device body 1 is set as a vibration drying drum 8, and the bottom of the vibration drying drum 8 is fixedly equipped with a vibrator 5; the vibrating machine 5 is provided with a vibration drying plate 501, and the vibration drying The plate 501 is arranged on the inner side of the vibrating drying cylinder 8; the upper side of the vibrating drying cylinder 8 is provided with a feeding po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com