Horizontal double-stirring proportioning tank

A technology of double stirring and batching tanks, which is applied to mixers with rotating stirring devices, dissolving machines, mixers, etc., can solve the problems of dead corners in sanitation, poor stirring effect of a single stirring paddle, etc., to avoid dead ends, shorten production time, and transport convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

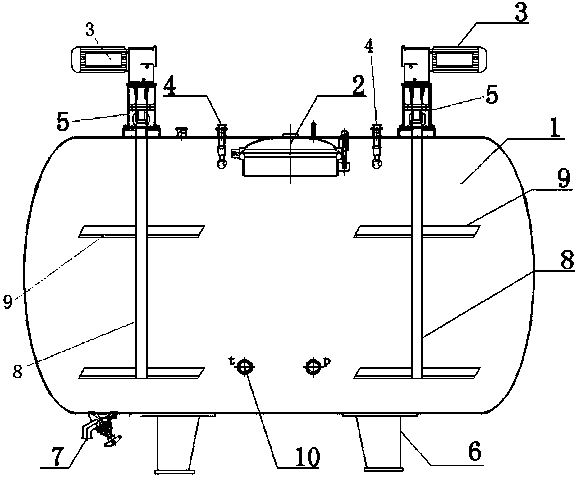

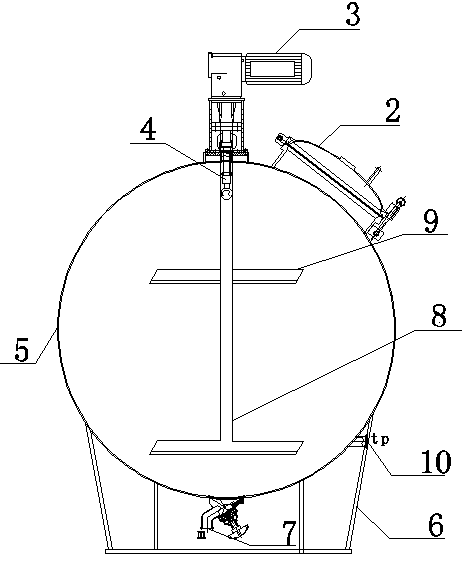

[0015] like figure 1 and figure 2 The shown horizontal double stirring batching tank consists of a horizontal cylinder 1, several saddles 6 arranged at the bottom of the horizontal cylinder 1, and a manhole 2 arranged on the horizontal cylinder 1, and symmetrically arranged A set of ports 4 on both sides of the manhole 2 on the horizontal cylinder 1, a sterile discharge valve 7 disposed at the bottom end of the horizontal cylinder 1, and a stirring assembly disposed on the horizontal cylinder 1 Composition; the mixing assembly includes a group of frames 5 symmetrically arranged on the horizontal cylinder 1, and a drive motor 3 arranged on the frame 5, and one end is located in the horizontal cylinder 1, and the other end is connected to the drive A stirring shaft 8 connected to the motor 3, and several stirring paddles 9 arranged on the stirring shaft 8.

[0016] Further preferably, the horizontal double stirring batching tank also includes a group of detection ports 10 sym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com