Water spout structure

A water nozzle and water flow technology, applied in the direction of spraying device, spraying device, etc., can solve the problems of large volume, inability to form effective water column, etc., achieve simple structure, good water spraying effect, and reduce the probability of water leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

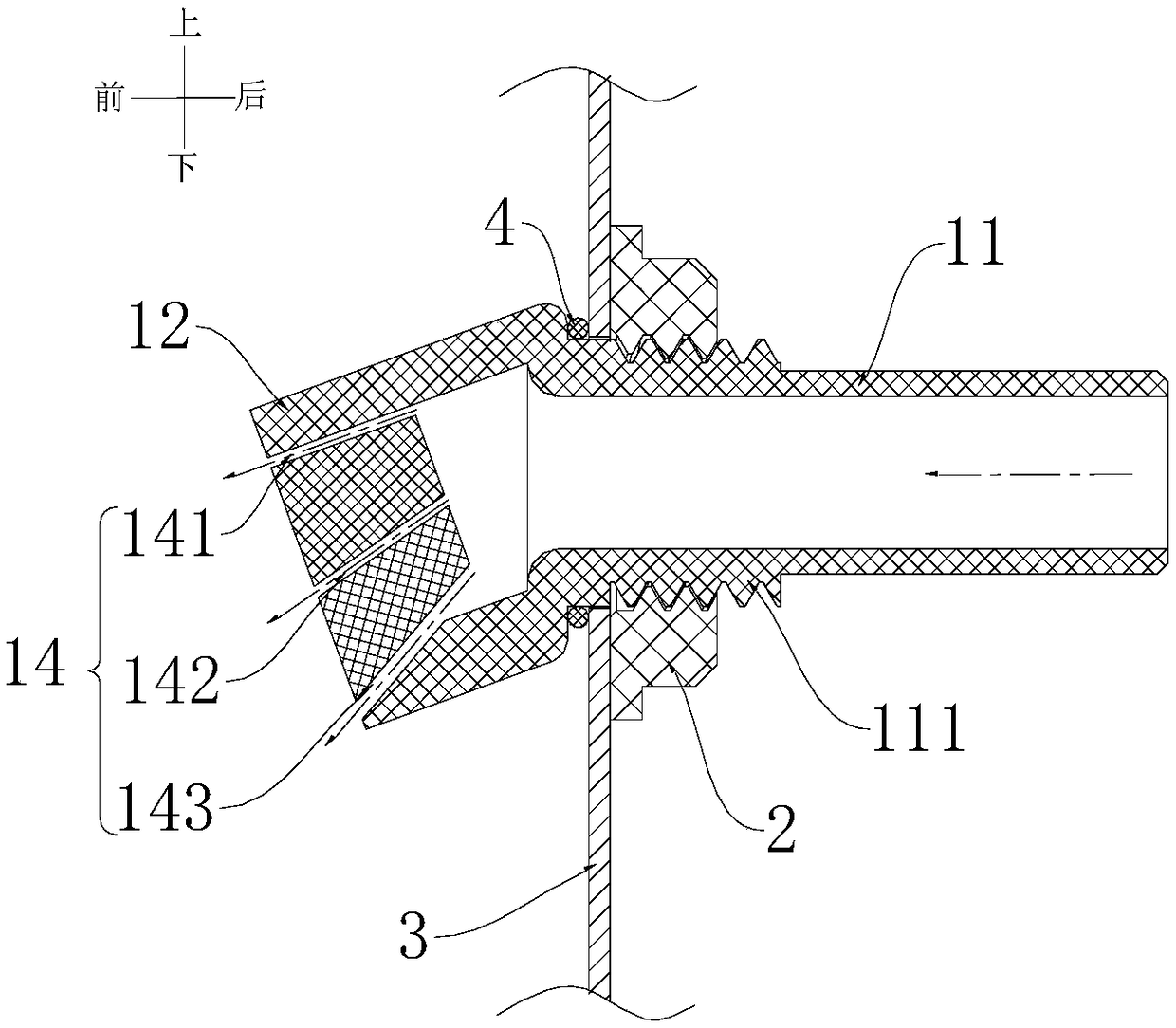

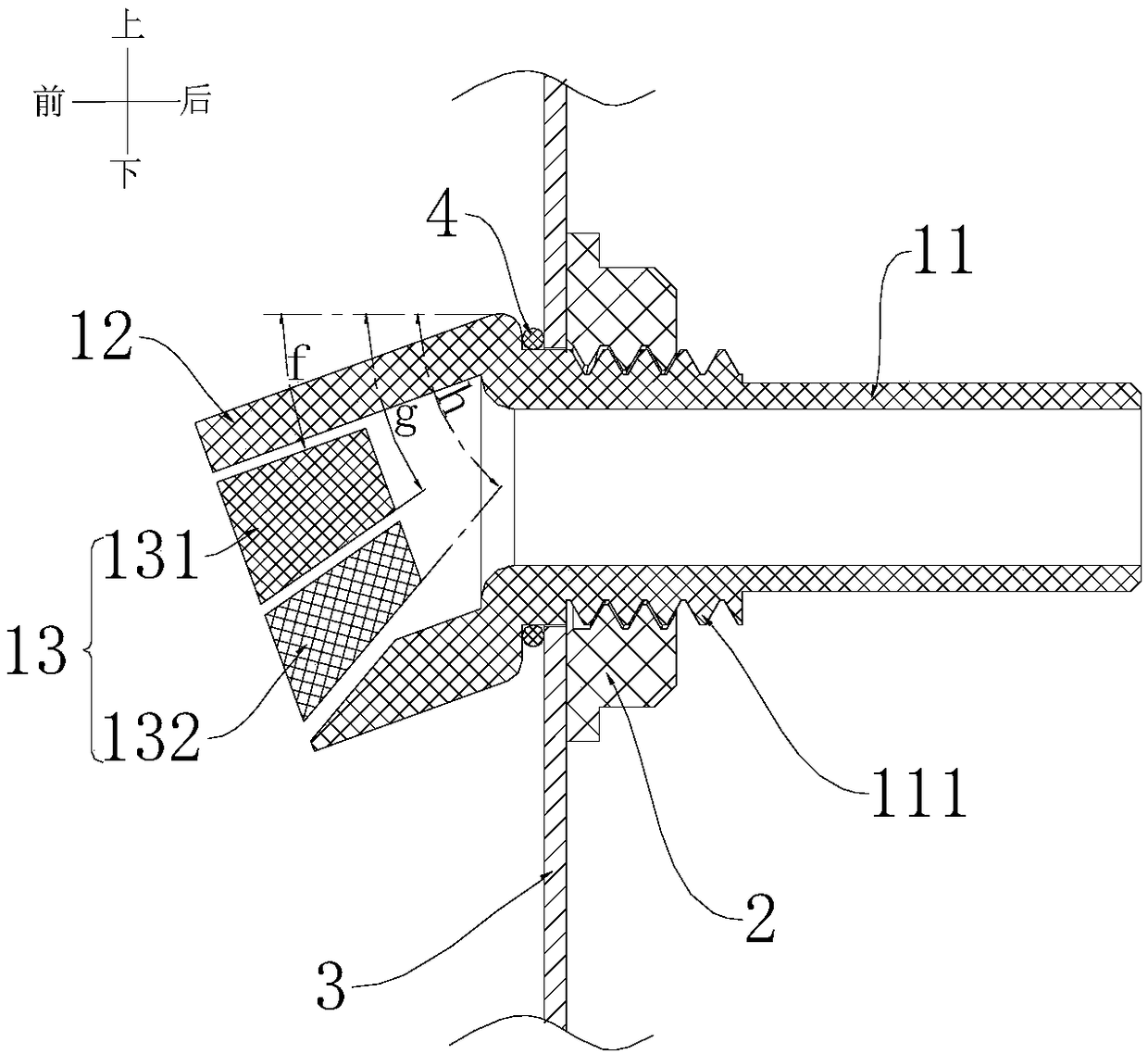

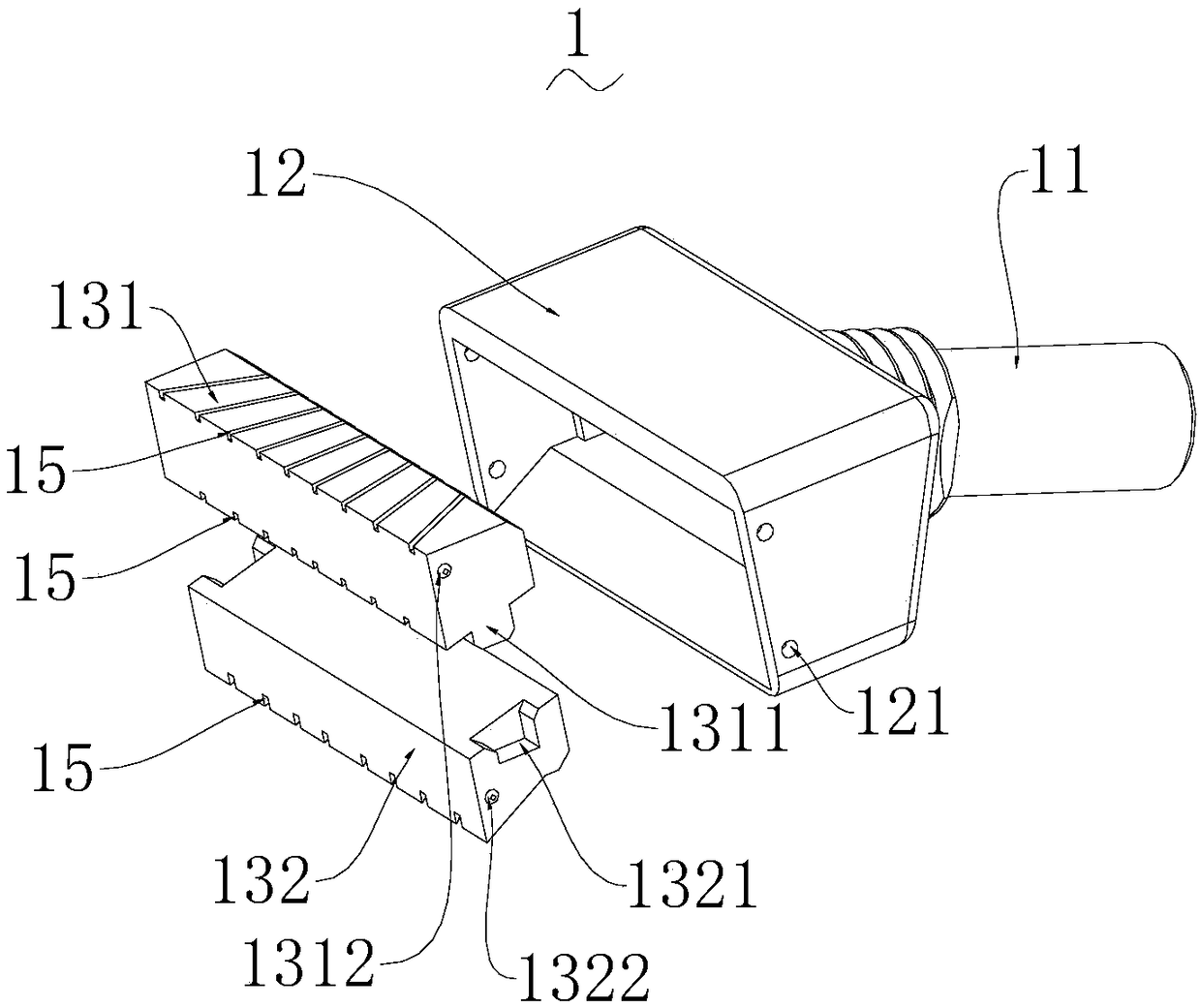

[0039] see Figure 1 to Figure 3 shown, which are respectively the schematic cross-sections of the water nozzle structure of the present invention Figure 1 , cross section Figure II And the explosion diagram of the water nozzle body.

[0040] to combine Figure 1 to Figure 3 As shown, a water nozzle structure includes a water nozzle body 1, and the water nozzle body 1 includes a water inlet portion 11 and a water outlet portion 12 that communicate with each other, and a plurality of flow dividers 13 are arranged in the water flow portion 12, and the flow divider 13 Separate multiple layers of water flow channels 14, there is an angle between any two layers of water flow channels 14, each layer of water flow channels 14 includes a plurality of water flow holes 15, when in use, water flows in from the water inlet 11 and is sprayed out from the water flow holes 15, form a column of water. In this embodiment, there is an included angle between any two water flow holes 15 on ...

Embodiment 2

[0045] As with the water nozzle structure described in Embodiment 1, the difference of this embodiment is that the cross-sectional area of the water inlet part 11 is j, and the sum of the cross-sectional areas of all water flow holes 15 is k, where j / k>5, when If the ratio of j / k is too small, a larger water inlet pressure will be required to form a water column in the nozzle structure, which will affect the user's experience of use, and the requirements for the use scene of the nozzle structure will also be increased.

[0046] In this embodiment, it is preferred that j / k=6, which can not only ensure the formation of the water column, but also ensure a certain amount of water, so that the user experience is the best.

[0047] In the water nozzle structure of the present invention, the relationship between the cross-sectional area of the water flow hole and the cross-sectional area of the water inlet is designed to ensure that the water nozzle structure can still form a wa...

Embodiment 3

[0049] The water nozzle structure as described in the second embodiment, the difference of this embodiment is that, as figure 1 As shown, the multi-layer water flow channels 14 are arranged sequentially from top to bottom, and the water outlet end of each layer of water flow channels 14 has a distance from the water inlet part 11, and the distance decreases successively from top to bottom, so that the entire front end of the water outlet part 12 faces down slope.

[0050] The nozzle structure in the present invention is provided with the relative position of the water outlet part 12 and the water inlet part 11, that is, the position of the water outlet end of the multi-layer water flow channel 14 is arranged close to the water inlet part 11 successively from top to bottom, so that each layer is sprayed out. The difference in the horizontal distance of the water column is more obvious, which improves the spraying effect of the nozzle structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com