Method for large-diameter shield tunnel segment monitoring cable to pass through second lining

A shield tunnel segment and large-diameter technology, which is applied in the direction of tunnel lining, tunnel lining, shaft lining, etc., can solve problems such as the influence of sensor cables, avoid signal loss, shorten monitoring interruption time, and reduce the probability of water leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

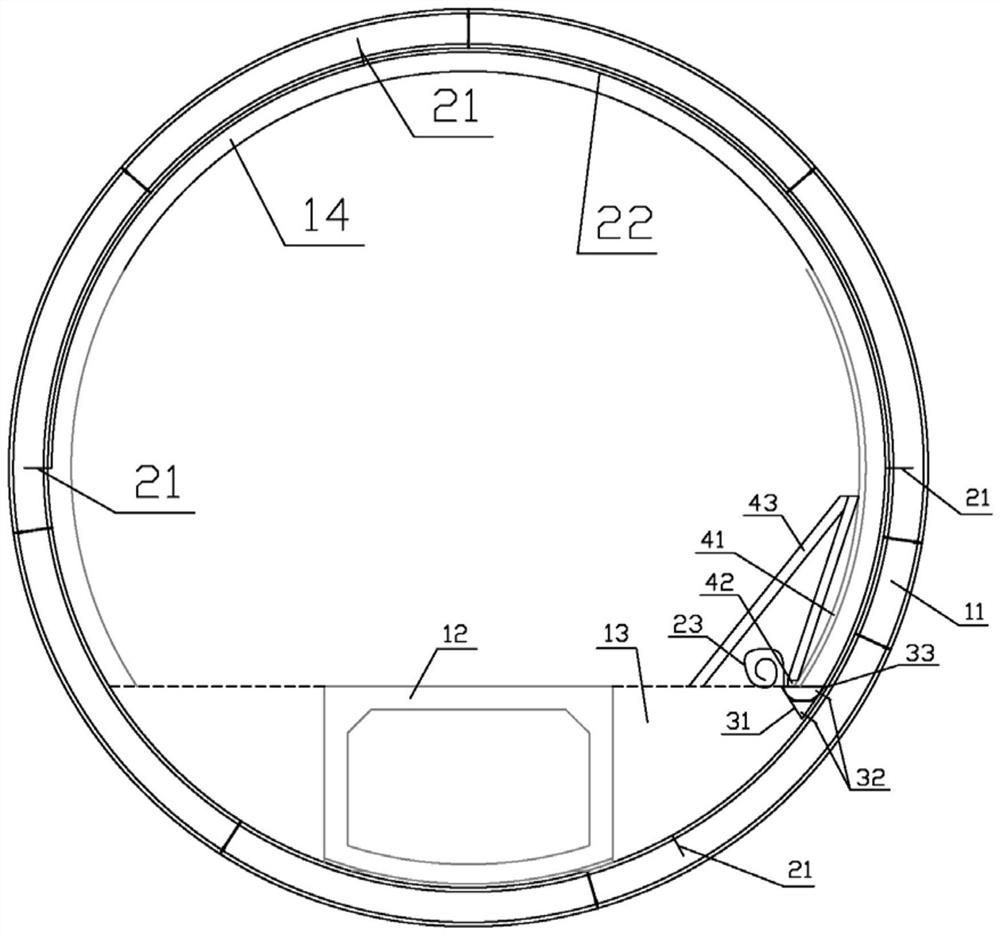

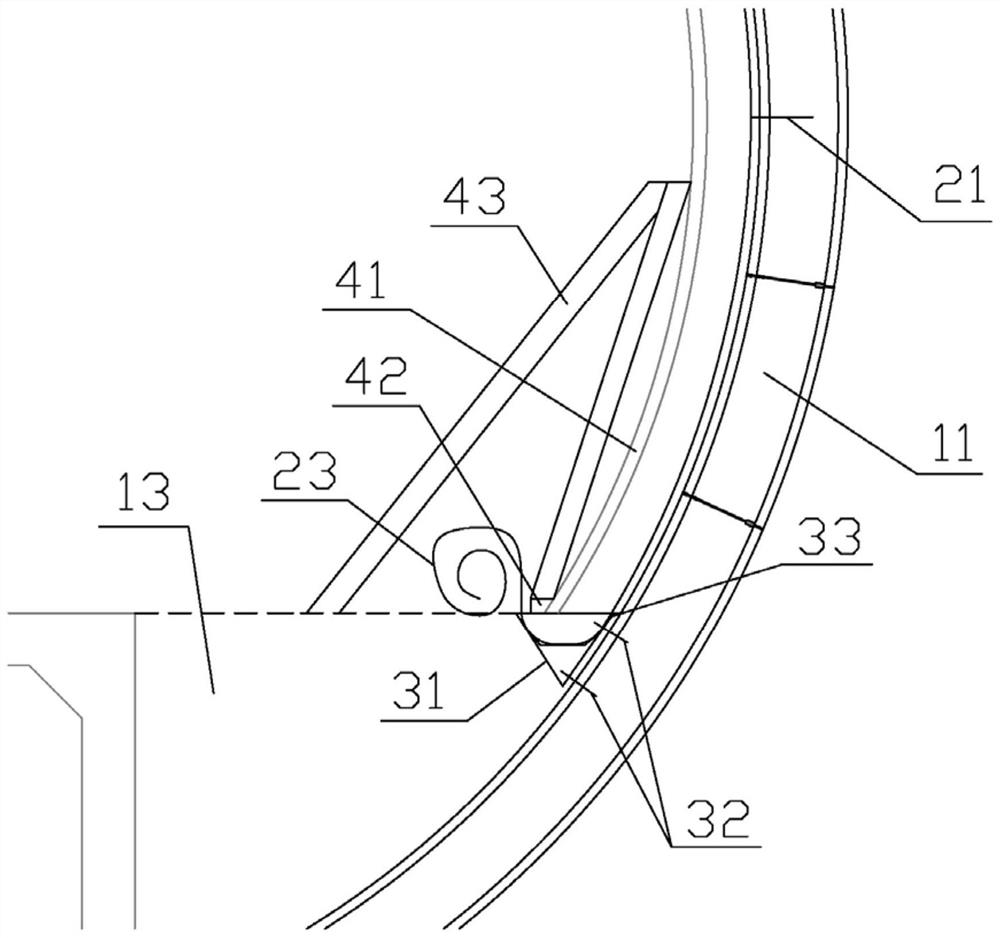

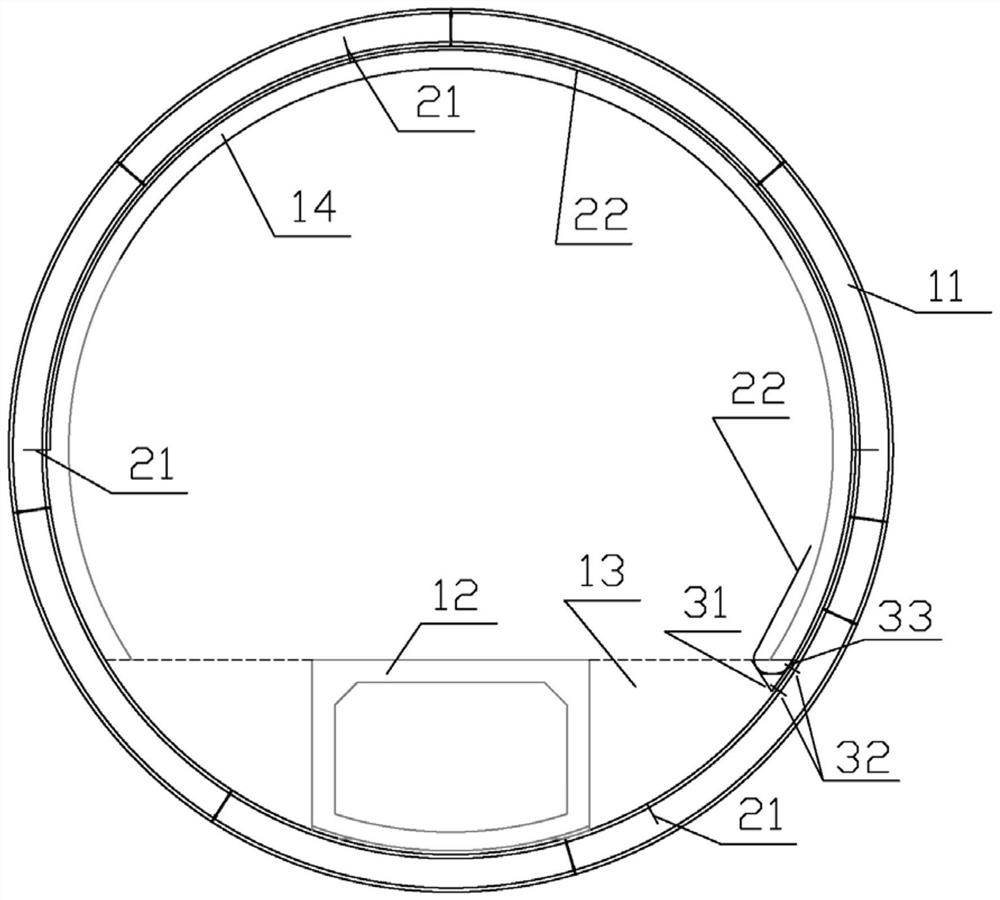

[0069] Such as Figure 1-3 As shown, the present invention provides a method for the large-diameter shield tunnel segment monitoring cable to pass through the second lining, which is a method for the large-diameter shield tunnel segment monitoring sensor cable to pass through the second lining under the double-layer lining design. Method, under the premise that the second lining is poured in stages, before the backfill concrete on both sides of the opening is poured, the cable is passed to the backfill position of the opening and fixed at a specific position, so that the sensor cable is wound out to the second lining concrete steel On the outside of the formwork, after the concrete of the second lining is poured, the cables are fixed to the surface of the concrete of the second lining to complete the fixing of the cables. Specifically, under the premise that the second lining is poured in stages, before backfilling concrete on both sides of the opening, the brackets and cable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com