Optical cable

A technology of optical cables and optical fiber lines, applied in the field of cables, can solve problems such as limited longitudinal compression resistance, large permanent deformation, and optical fiber extrusion, and achieve excellent anti-deformation ability, small impact and damage, and excellent structural stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

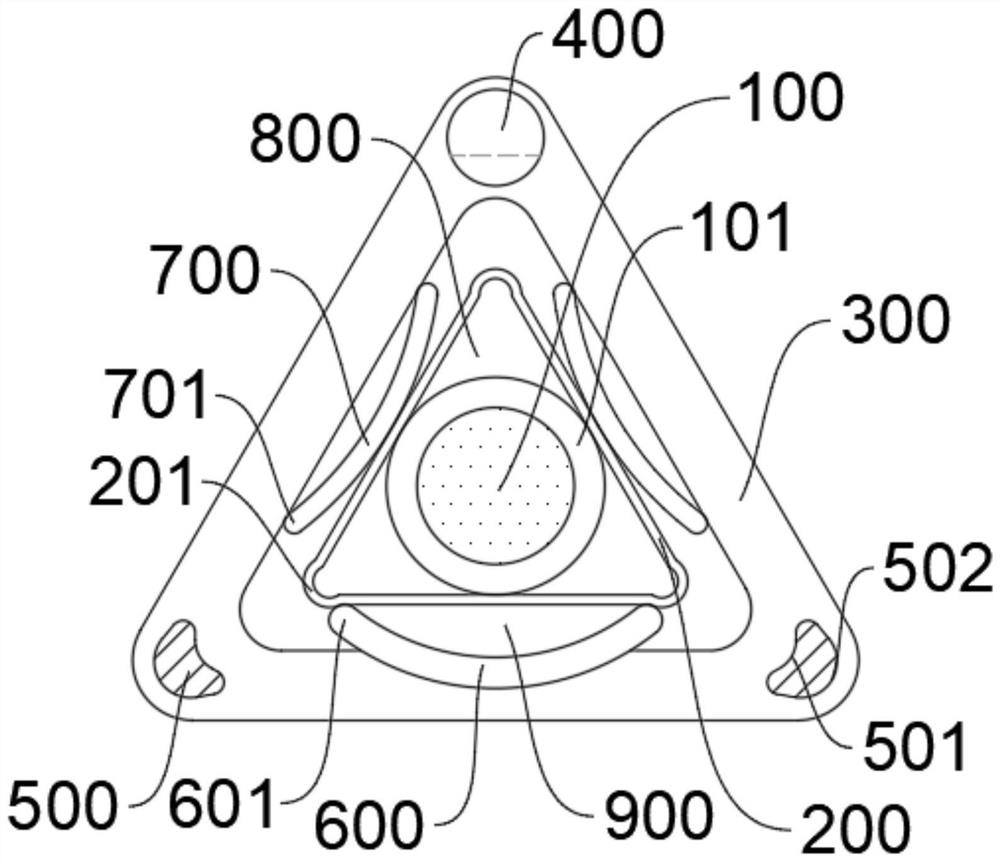

[0051] a kind of like figure 1 The fiber optic cable shown, which includes:

[0052] Optical fiber cable 100, inner sheath 200 and outer sheath 300;

[0053] The optical fiber cable 100 is composed of single-mode or multi-mode optical fiber, and its outer surface is tightly wrapped with a non-woven fabric tape 101 for preliminary protection. The non-woven fabric tape 101 mainly protects the optical fiber cable 100 from abrasion and achieves Moisture-proof effect;

[0054] The cross sections of the inner sheath 200 and the outer sheath 300 are both triangular in shape as shown in the figure. In this embodiment, both are preferably equilateral triangles. In general, it has been found through experiments that the triangle angle can be controlled within the range of 58-62° to achieve the same The substantially equivalent technical effect of present embodiment;

[0055] Wherein, the cross section of the outer sheath 300 is an equilateral triangle with rounded corners. When the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com