Combined plate heat exchanger with external communicating passage

A technology of plate heat exchangers and communication channels, applied in the direction of heat exchangers, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of deformation and water leakage of large plate heat exchangers, achieve convenient transportation and reduce water leakage rate , the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

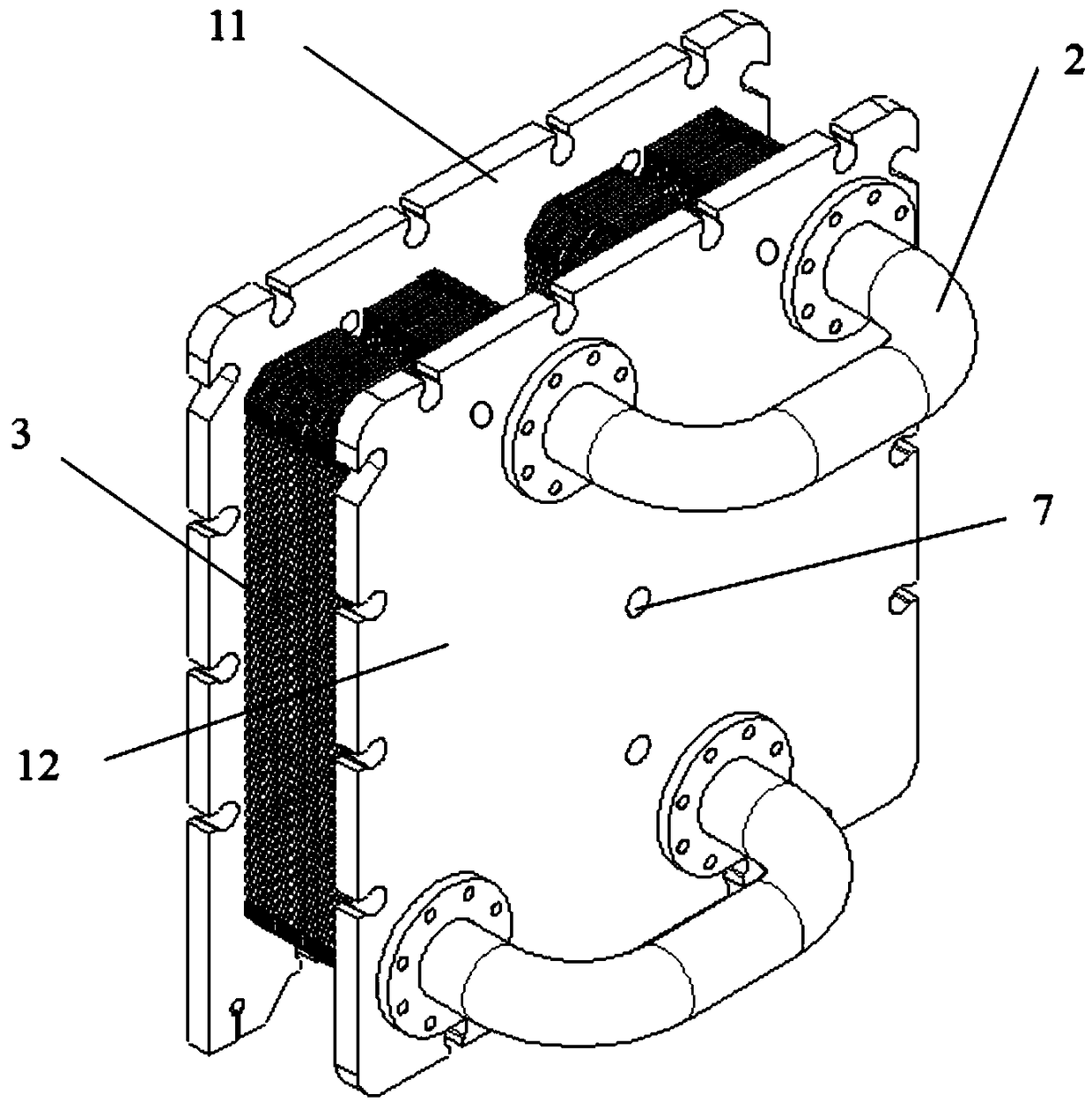

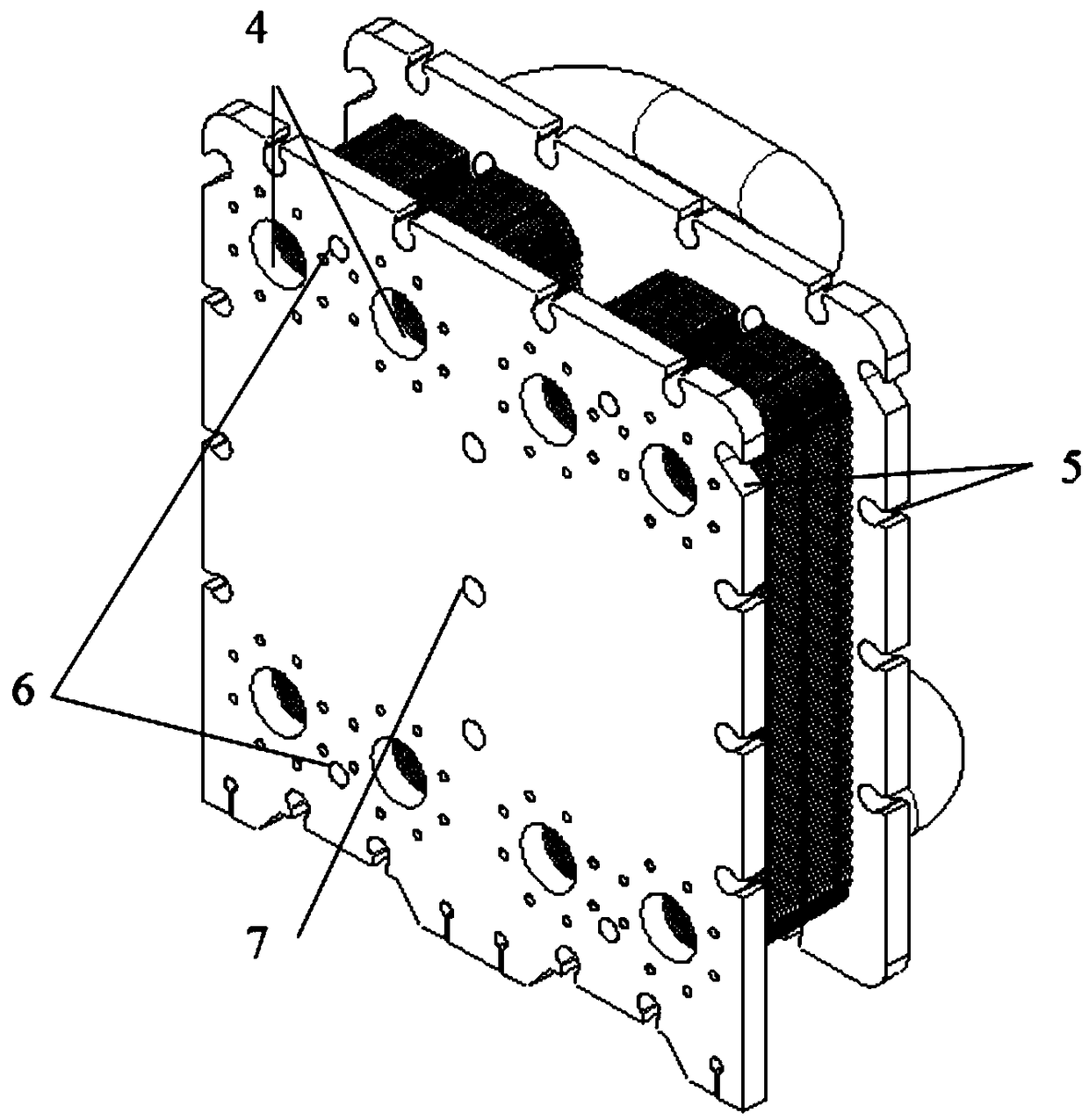

[0031] Several heat exchange plate bundle units 3 can be installed side by side between the fixed pressure plate 11 and the movable pressure plate 12, and the adjacent heat exchange plate bundle units 3 can be communicated through the outer tube 2, so that the heat exchange plate bundle units 3 They are connected in series, and at the same time, each heat exchange plate bundle unit 3 can also be installed with an outer tube 2 communicating with the internal medium hole of the heat exchange plate bundle unit 3, so that the heat exchange plate bundle units 3 are in a parallel state, It is also possible to mix parallel and series structures, so that the heat exchanger can be adjusted according to the actual needs of users, which expands the scope of application. The outer pipe 2 is used for transportation, which ensures the flow capacity of the heat exchanger and increases the heat exchange efficiency of the heat exchanger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com