A crankshaft drilling and clamping device

A clamping device and crankshaft technology, applied in the field of crankshaft processing, can solve the problems such as the inability to adjust the punching angle according to the needs, the waste occupying a large space, and whether it is troublesome.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

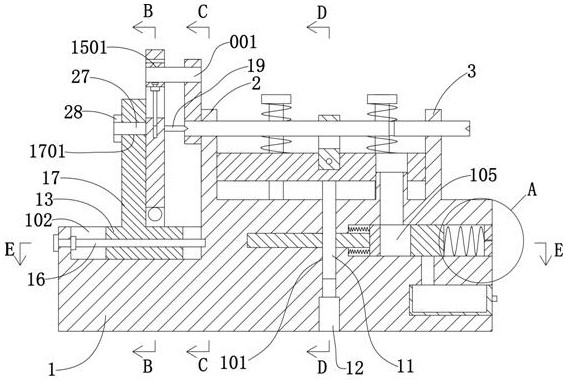

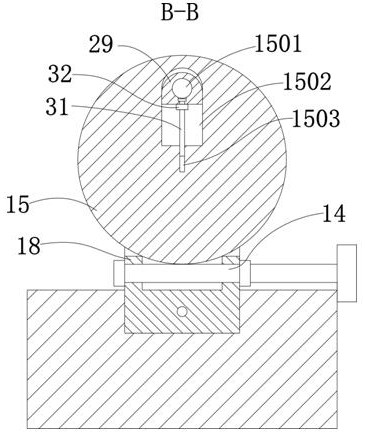

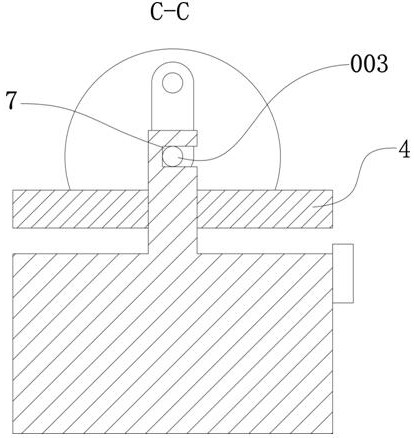

[0029] see Figure 1-10As shown, a crankshaft drilling clamping device includes a base 1, on which a left slide plate 2 and a right slide plate 3 are arranged side by side along the vertical direction upwards, on the base 1 there are left slide plate 2 and a right slide plate 3 A compression block 4 is vertically slidably connected between the right slide plates 3, and a first chute 401 is provided on the compression block 4 along the length direction perpendicular to the base 1, and the first chute 401 is slidably connected There is a compression pull plate 5, and the first screw rod 6 for driving the compression pull plate 5 to move along its length direction is connected in rotation in the first chute 401; the left slide plate 2 and the right slide plate 3 The first notch 7 for placing the long shaft 003 is provided on the side near the top position; notch 501 .

[0030] The base 1 is provided with four positioning slide bars 8 upwards in the vertical direction, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com