Welding fixture for laser circumferential seam welding of multi-layer thin-wall ring part

A technology of welding fixtures and ring parts, which is applied in laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of warping and deformation of parts welding, achieve good thermal conductivity and heat dissipation, and prevent welding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

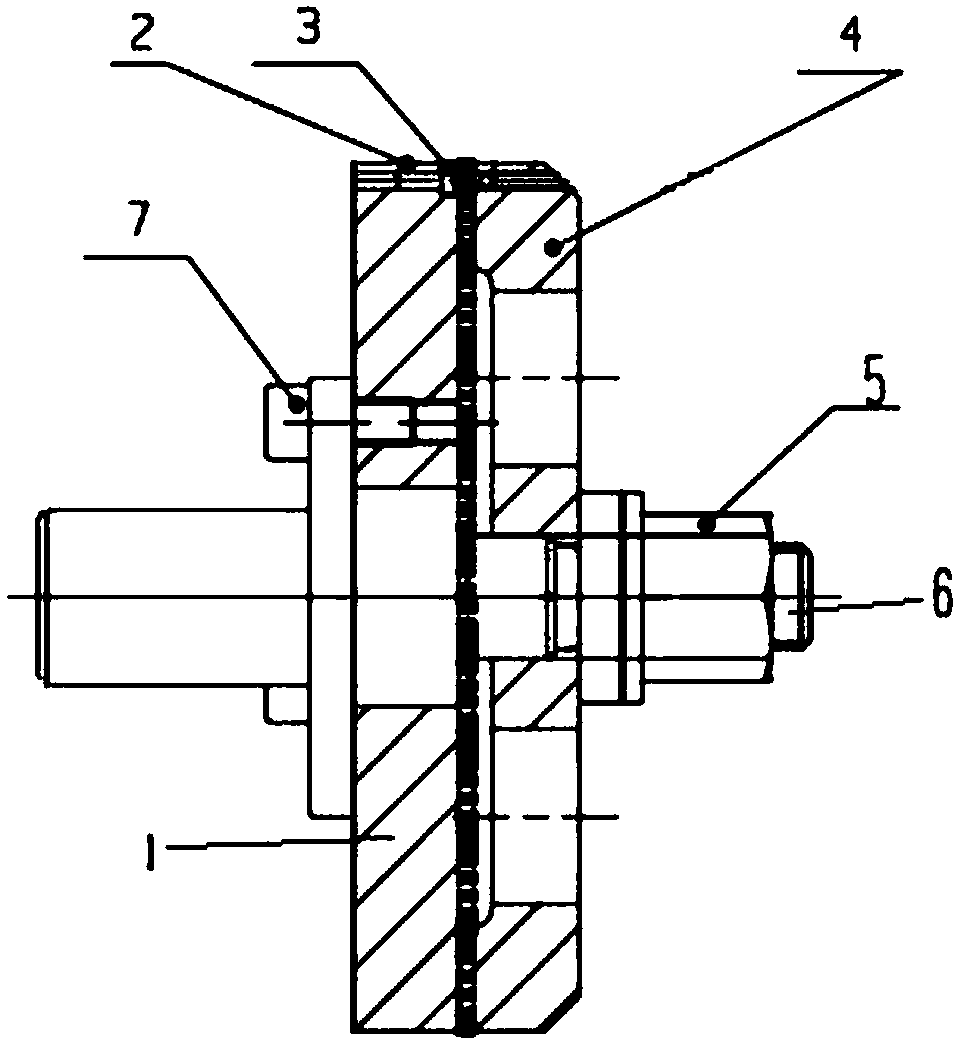

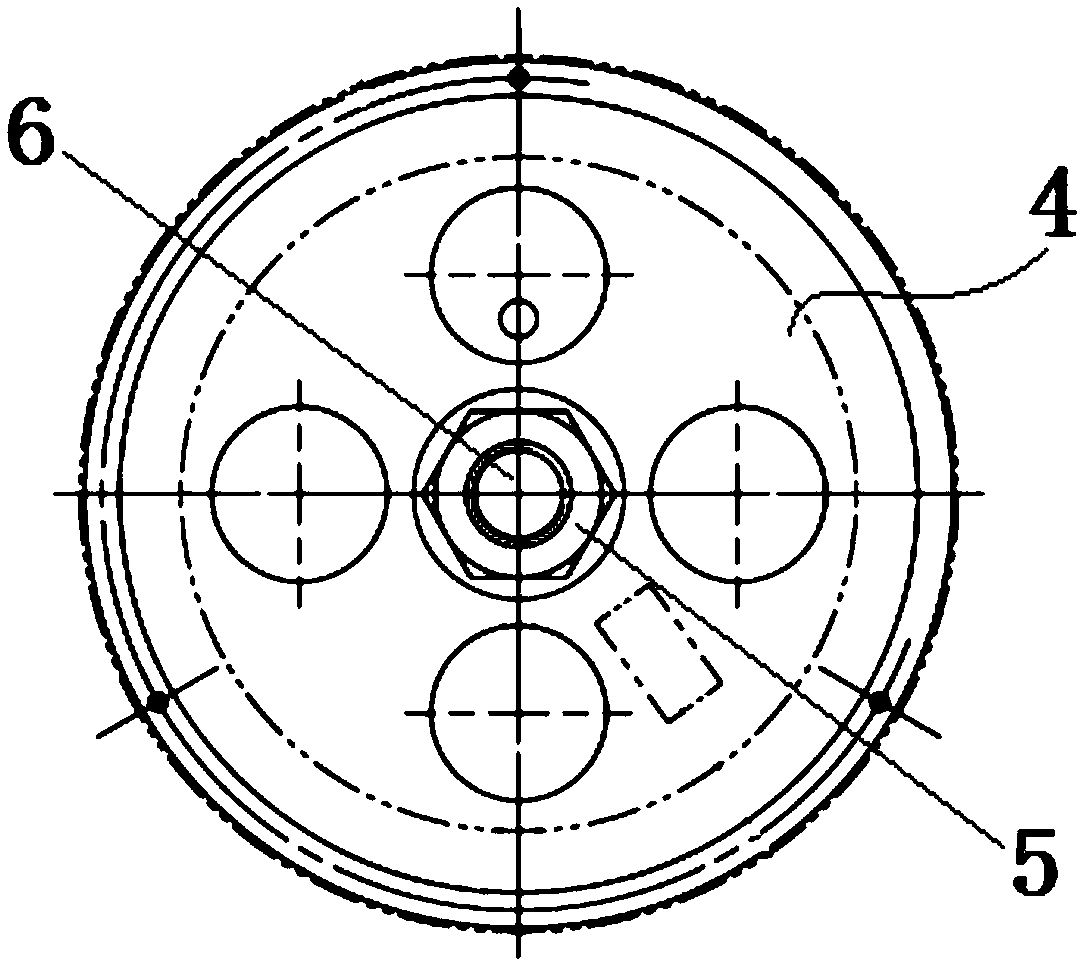

[0021] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0022] The invention provides a welding fixture for laser circumferential seam welding of multi-layer thin-walled annular parts, such as figure 1 As shown, including positioning plate 1, the material of positioning plate 1 is copper T2, and its surface is chrome-plated; three positioning pins 3 are distributed on positioning plate 1, and there are three threaded holes for connecting mandrel 2 on positioning plate 1 , the outer diameter of the positioning disc 1 is smaller than the outer diameter of the workpiece to be welded. When the workpiece is welded, the welding adhesion between the parts and the positioning disc 1 is avoided; The surface washer 6 is covered with a gland 4, and the conical washer 6 is also provided with a spherical shoulder nut 5, the spherical shoulder nut 5 is combined with the conical washer 6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com