Patents

Literature

35results about How to "Uniform compression force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Traditional chinese medicine composition for sober-up and hepatic protection and a process for preparing the same

ActiveUS20160310554A1Effectively soberRelieve drunkenness symptomsPowder deliveryDispersion deliverySteatosisAlcohol

The present invention relates to traditional Chinese medicine, particularly to a traditional Chinese medicine composition for sober-up and hepatic protection and a process for preparing the same. This composition is made from Radix Puerariae, Semen Hoveniae and Fructus Gardeniae. This composition has no significant effect on the body weight of mice. The hepatic TG level in animals of 1.400 g / kg·bw dosage group is significantly lower than that of the model control group, while the hepatic GSH level is significantly higher than that of the model control group. The degree of hepatic steatosis in animals of 1.400 g / kg·bw dosage group is significantly lower than that of the model control group. Therefore, the composition of the present invention has auxiliary protective effects on liver damages caused by alcohol. The process for preparing the composition comprises: extracting Radix Puerariae, Semen Hoveniae and Fructus Gardeniae with water, concentrating, drying, and pulverizing the extract.

Owner:INFINITUS (CHINA) CO LTD

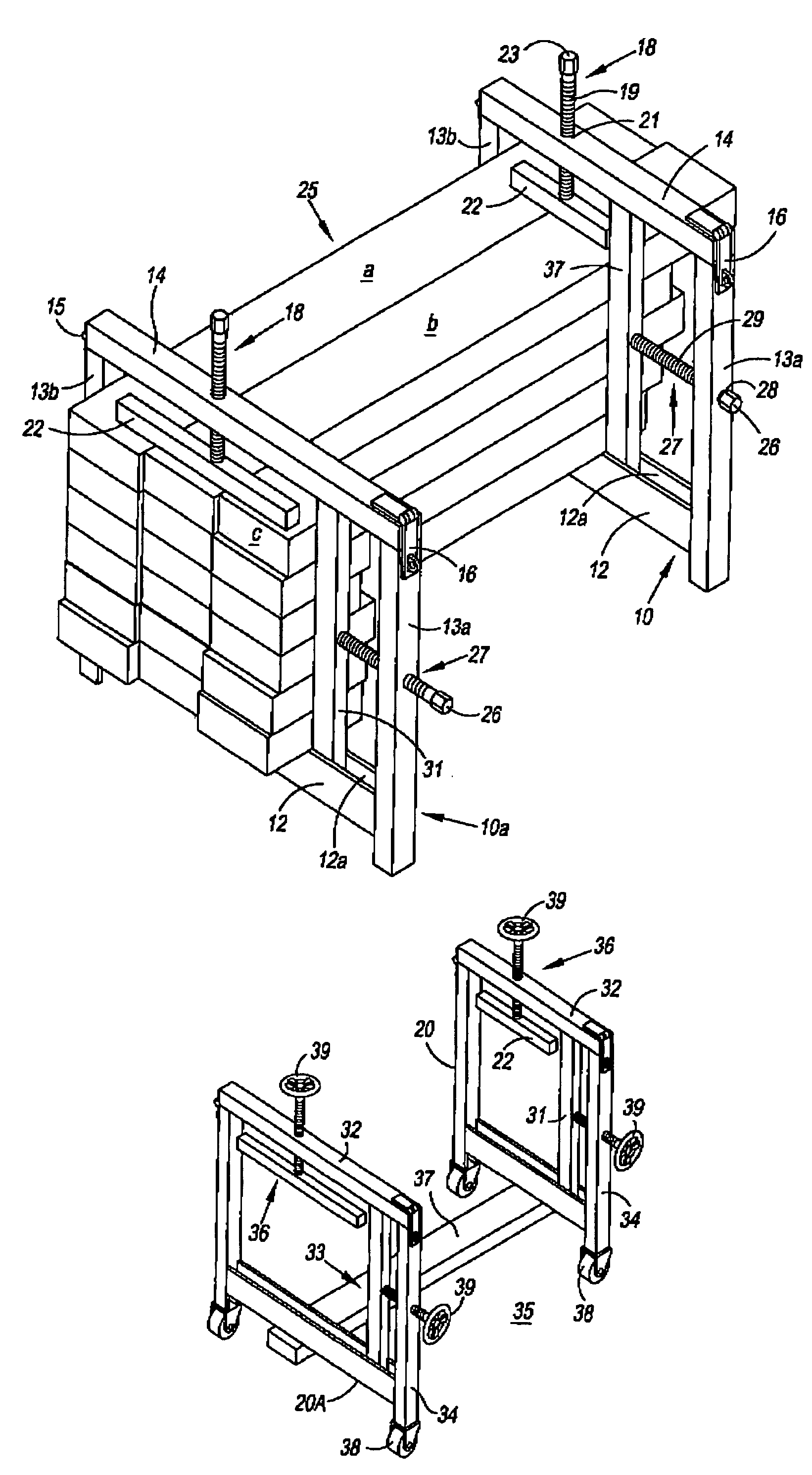

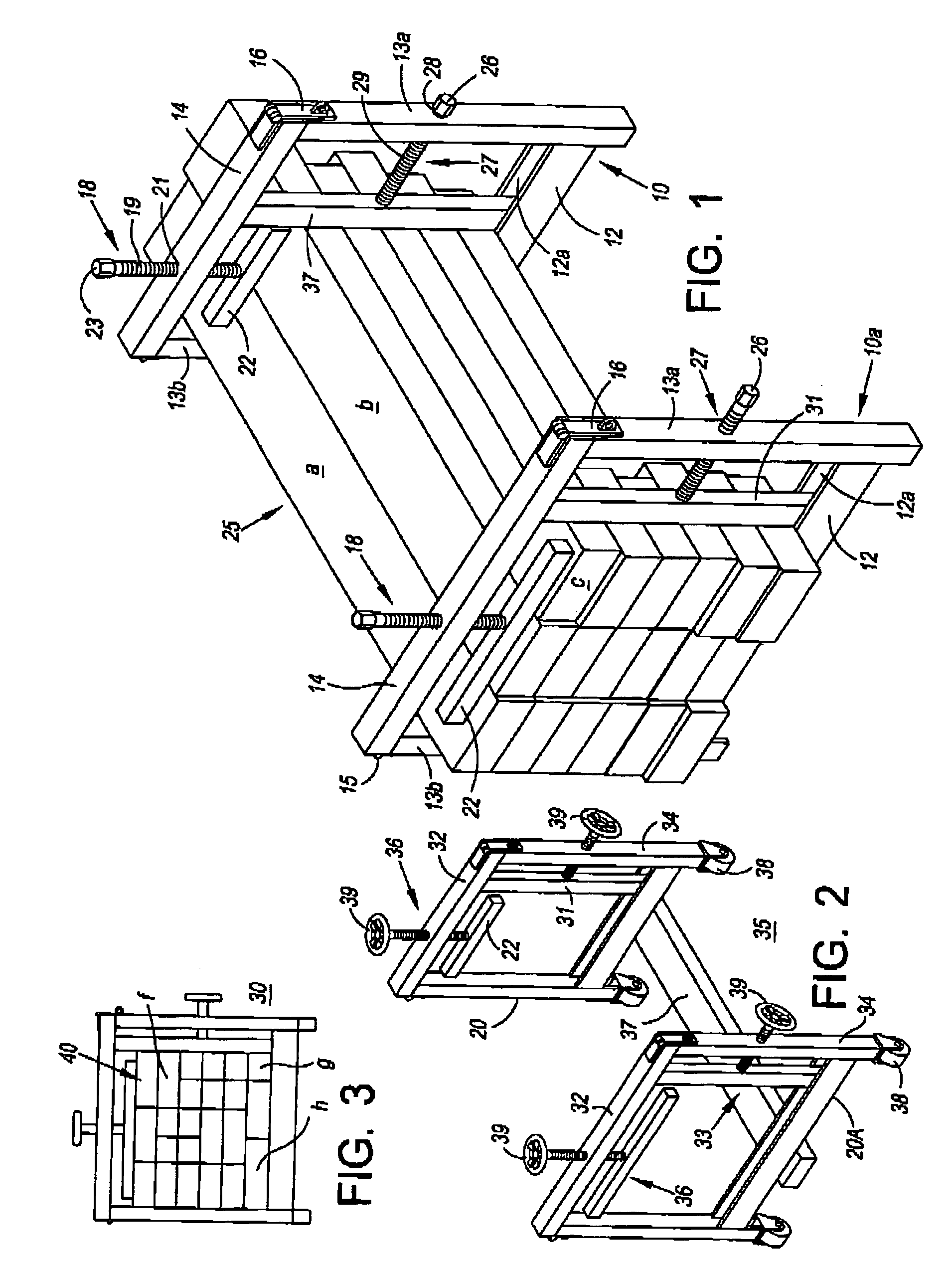

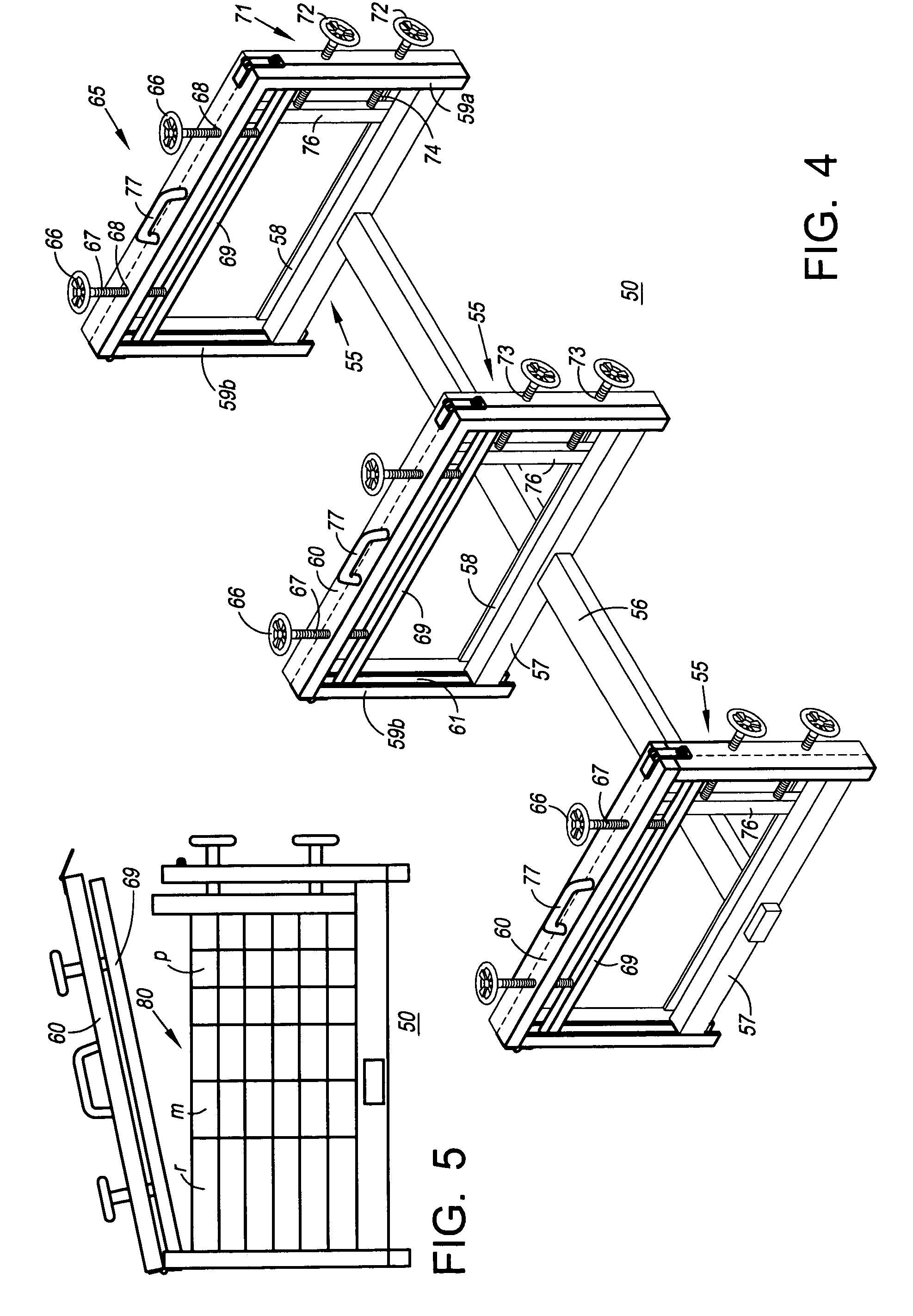

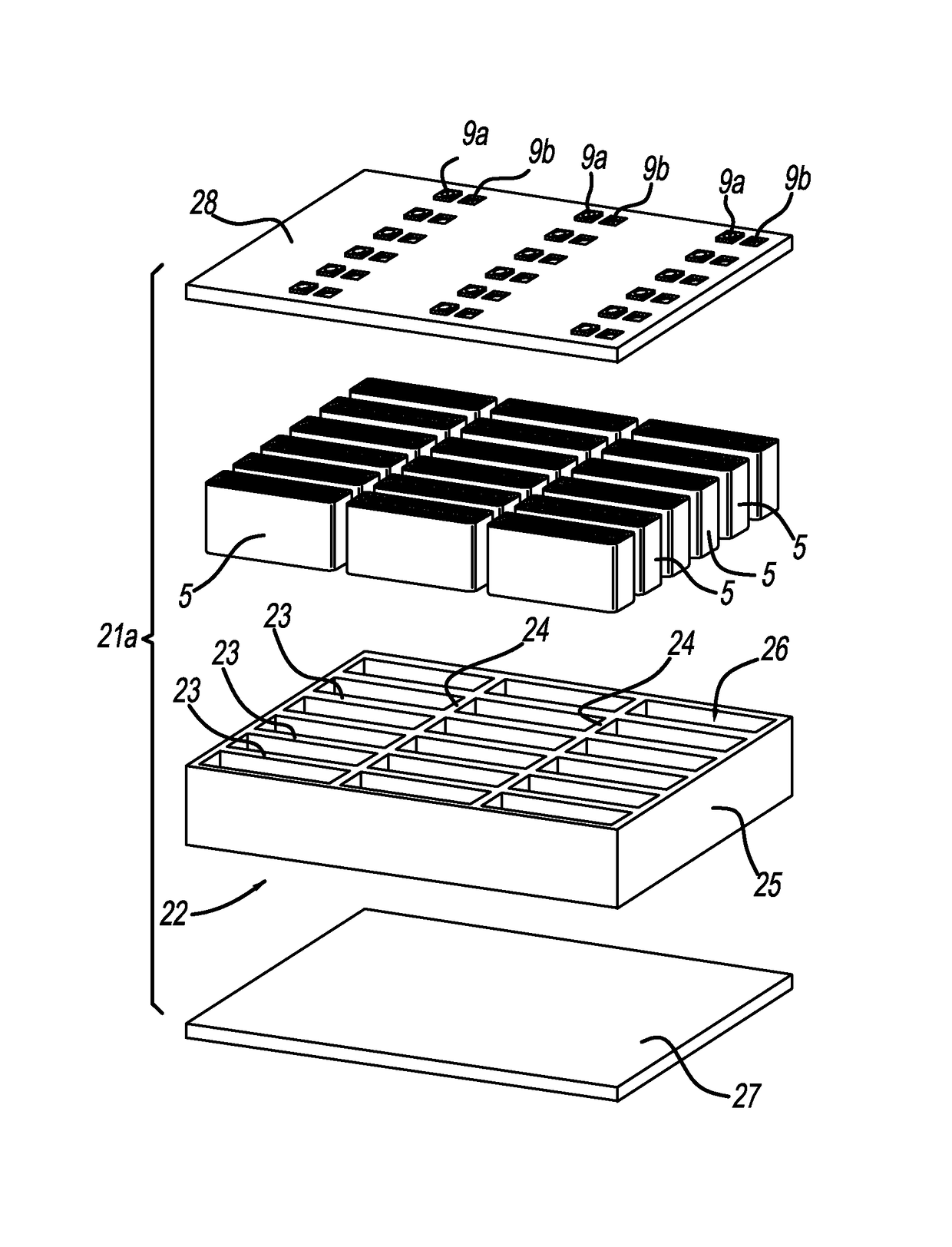

Warpage control method and apparatus

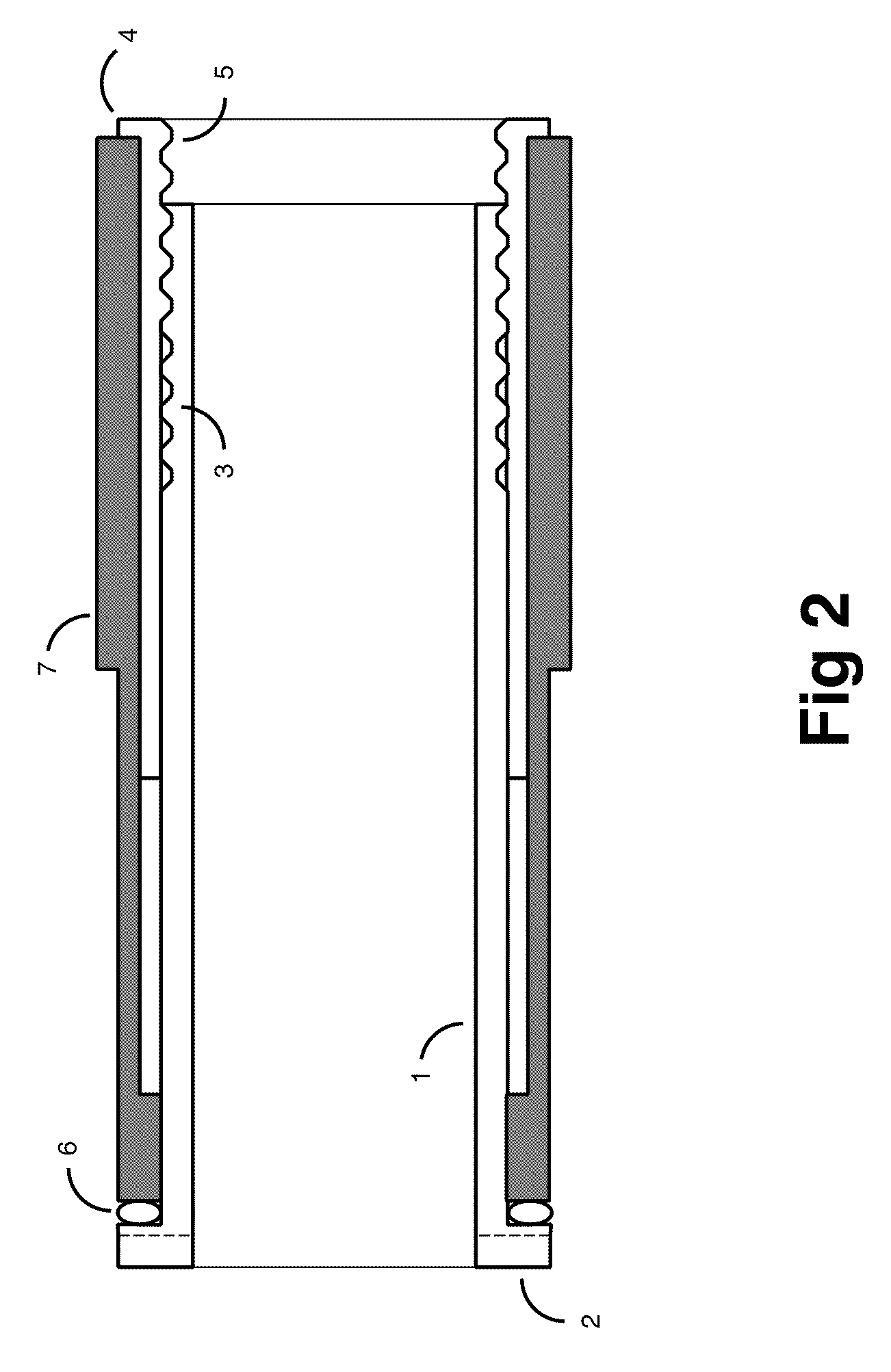

InactiveUS7014180B1Uniform compression forceAvoiding or correcting warpage of lumberLarge fixed membersPositioning apparatusEngineeringActuator

Method and apparatus for storing stacks of lumber to avoid or correct warpage utilizing two or more rectangular or square frameworks, open throughout which may include linkage for maintaining a fixed spacing of the frameworks and / or rollers for mobility in handling the stacks of lumber. A side of each framework may be hinged for opening and include a latch mechanism for securing such side from opening. Two adjacent sides of each framework each mount a force actuator having a flat face member supported within the interior periphery of each framework for engagement with the exposed surface of the stacks of lumber positioned within and extending between the two or more frameworks which upon activation of the force actuator squeezes the stack of lumber in two directions, thereby avoiding or correcting warpage during storage of the stacks of lumber. Further, where the stack of lumber does not present a uniform exposed adjacent surfaces filler blocks are used to provide such surfaces initially or whenever a price of lumber is removed from the stack.

Owner:HARRISON DOUGLAS W

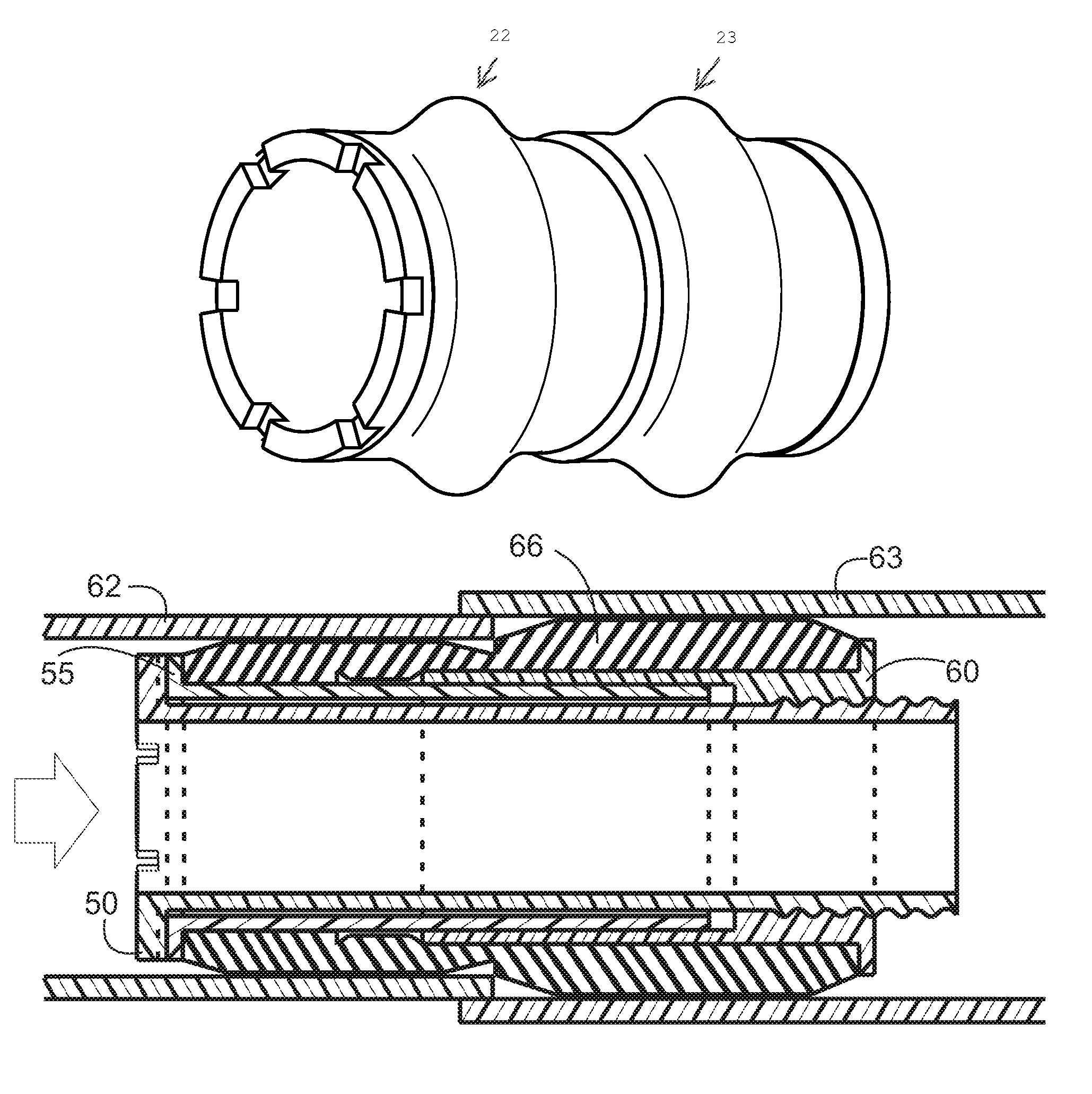

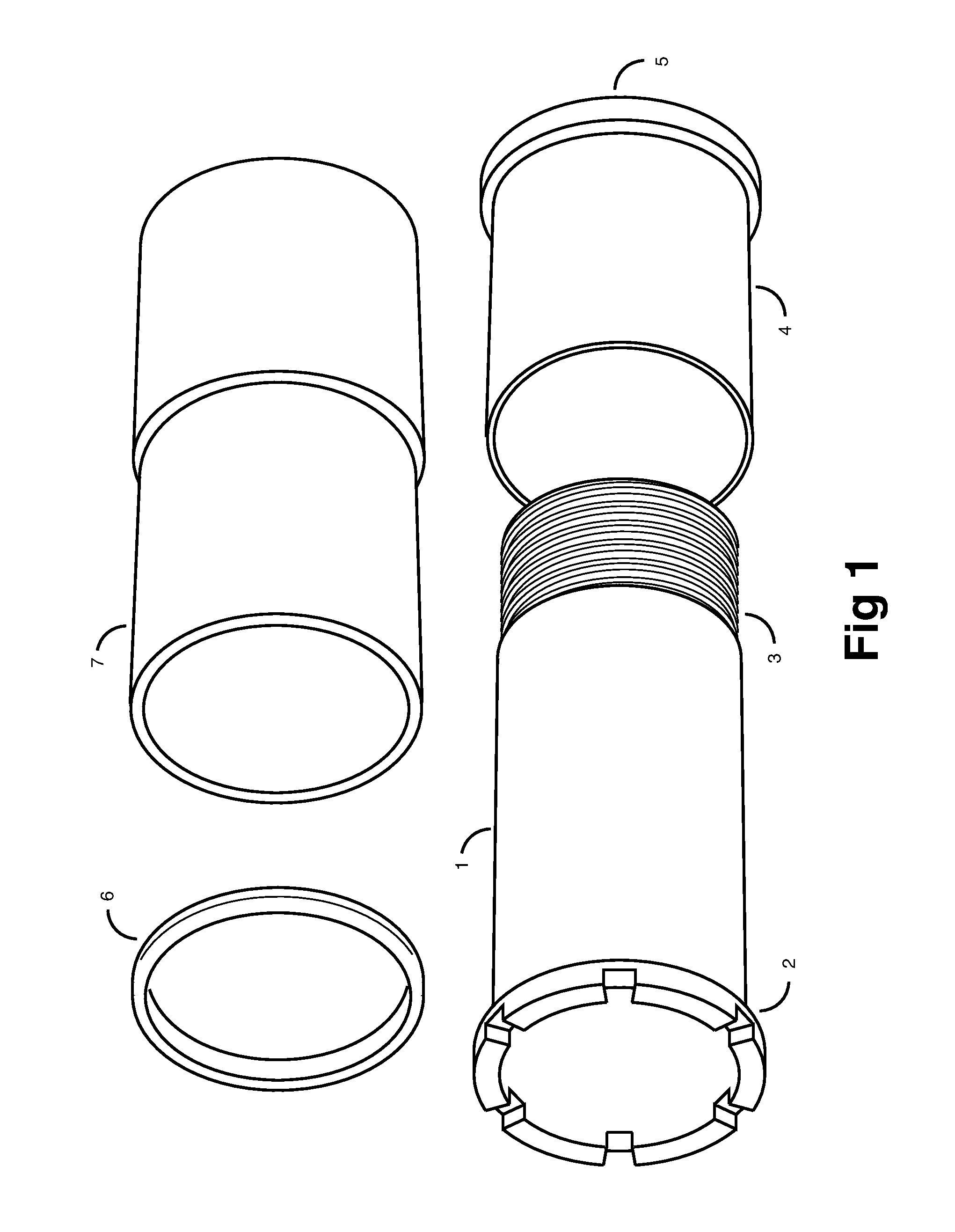

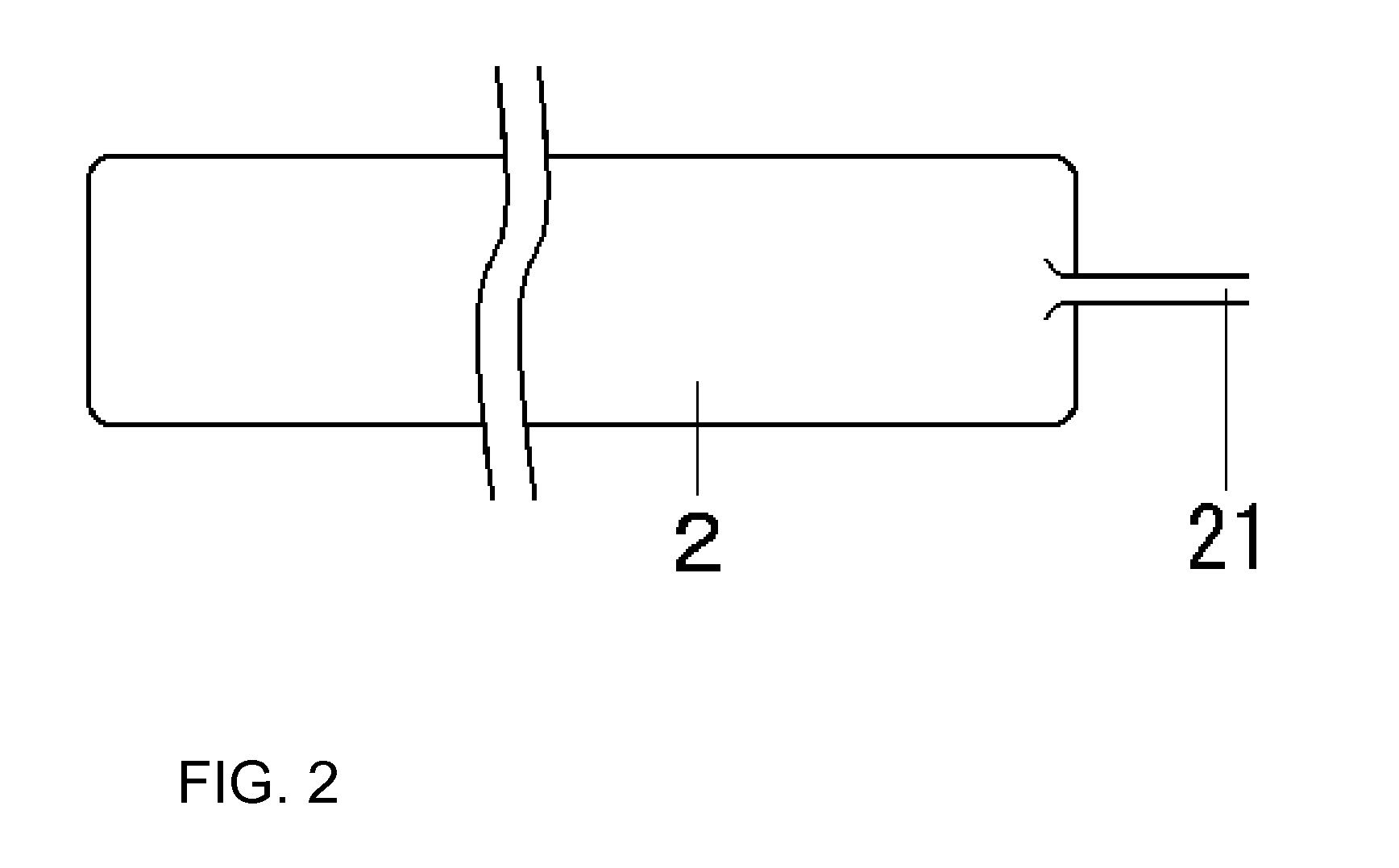

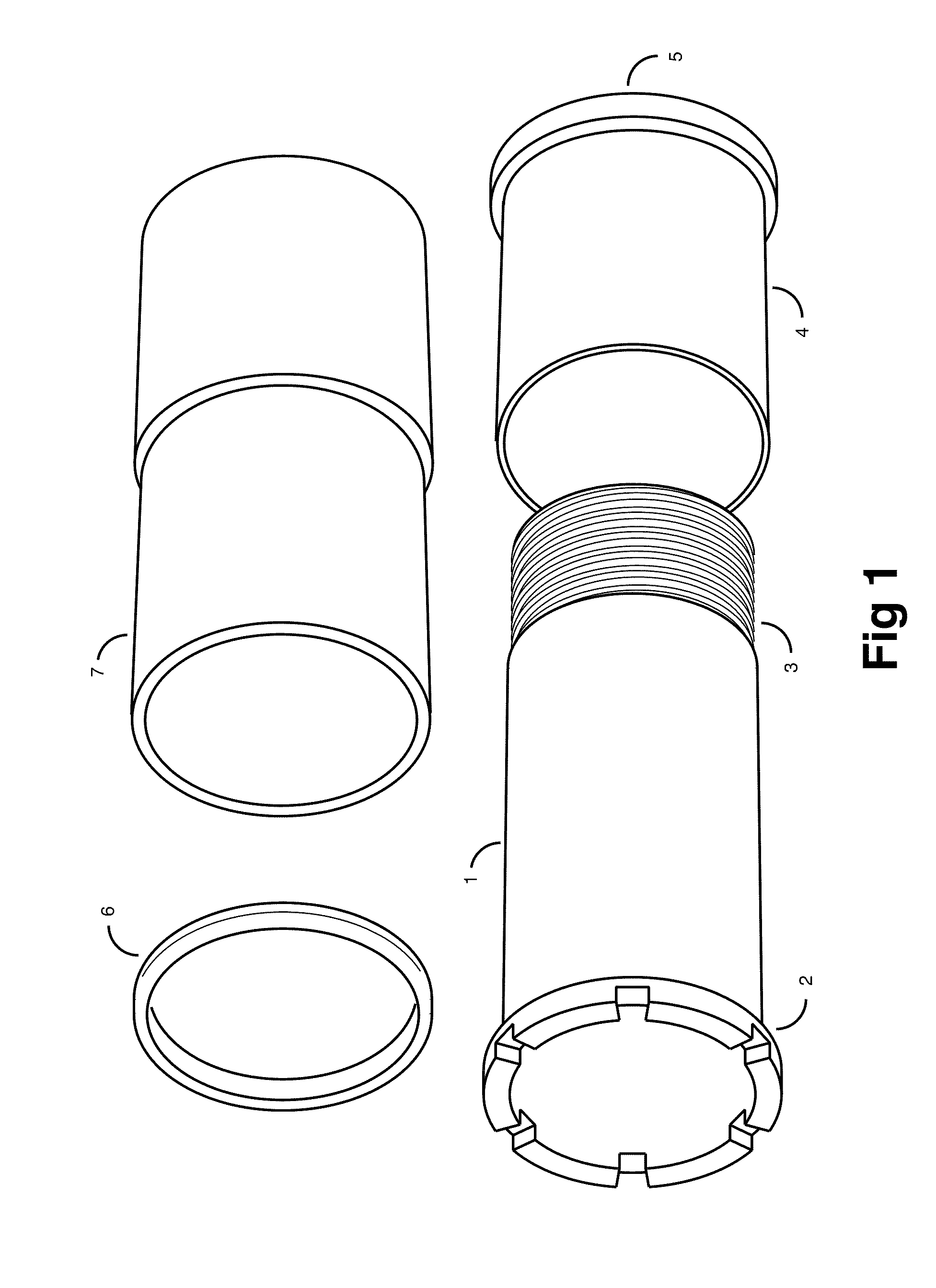

Sealable drain pipe coupling

ActiveUS8534715B2Easy to installReduces time effortSleeve/socket jointsWater closetsCouplingBiomedical engineering

Owner:ABBASI ABDUL LATIF +1

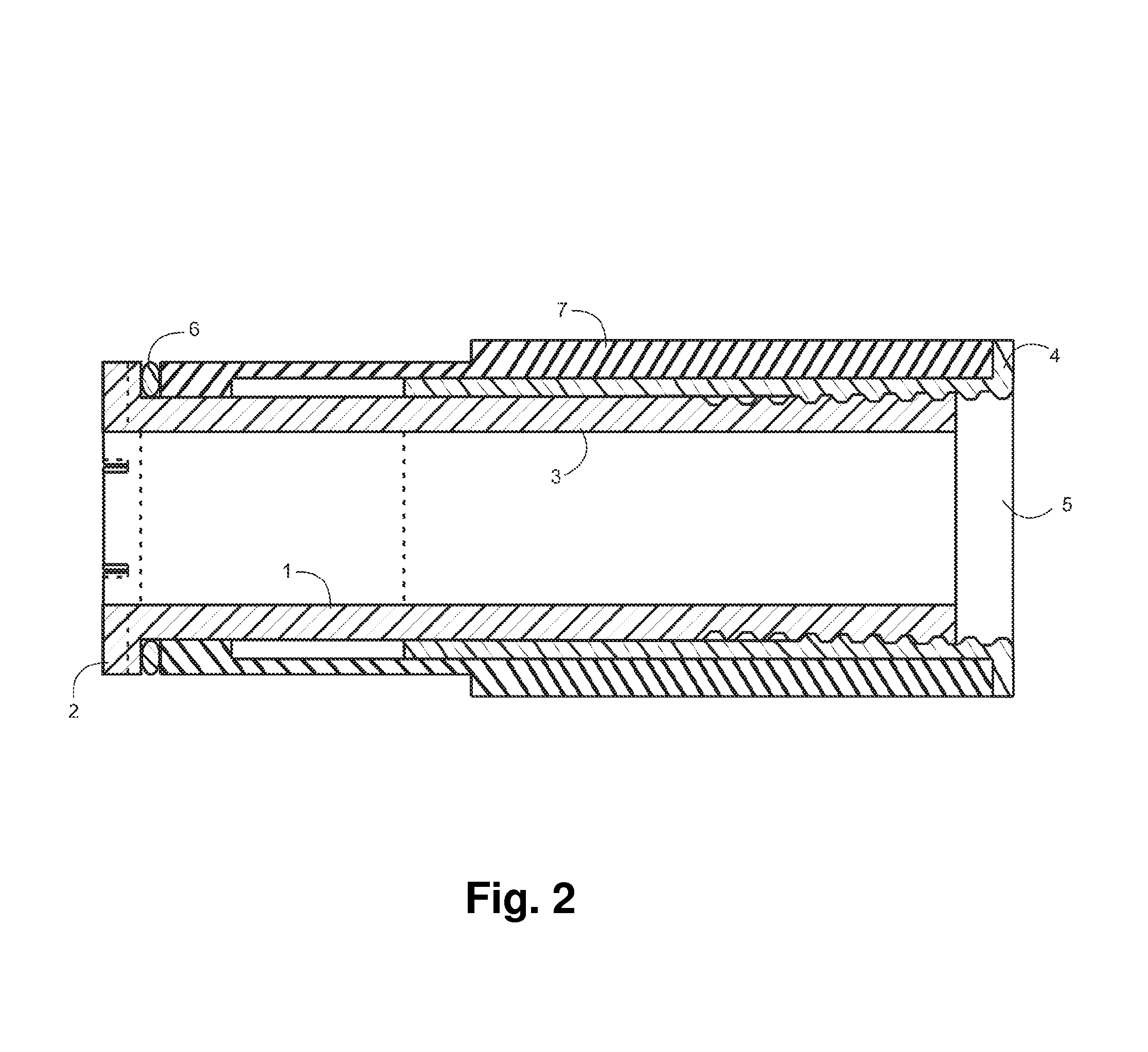

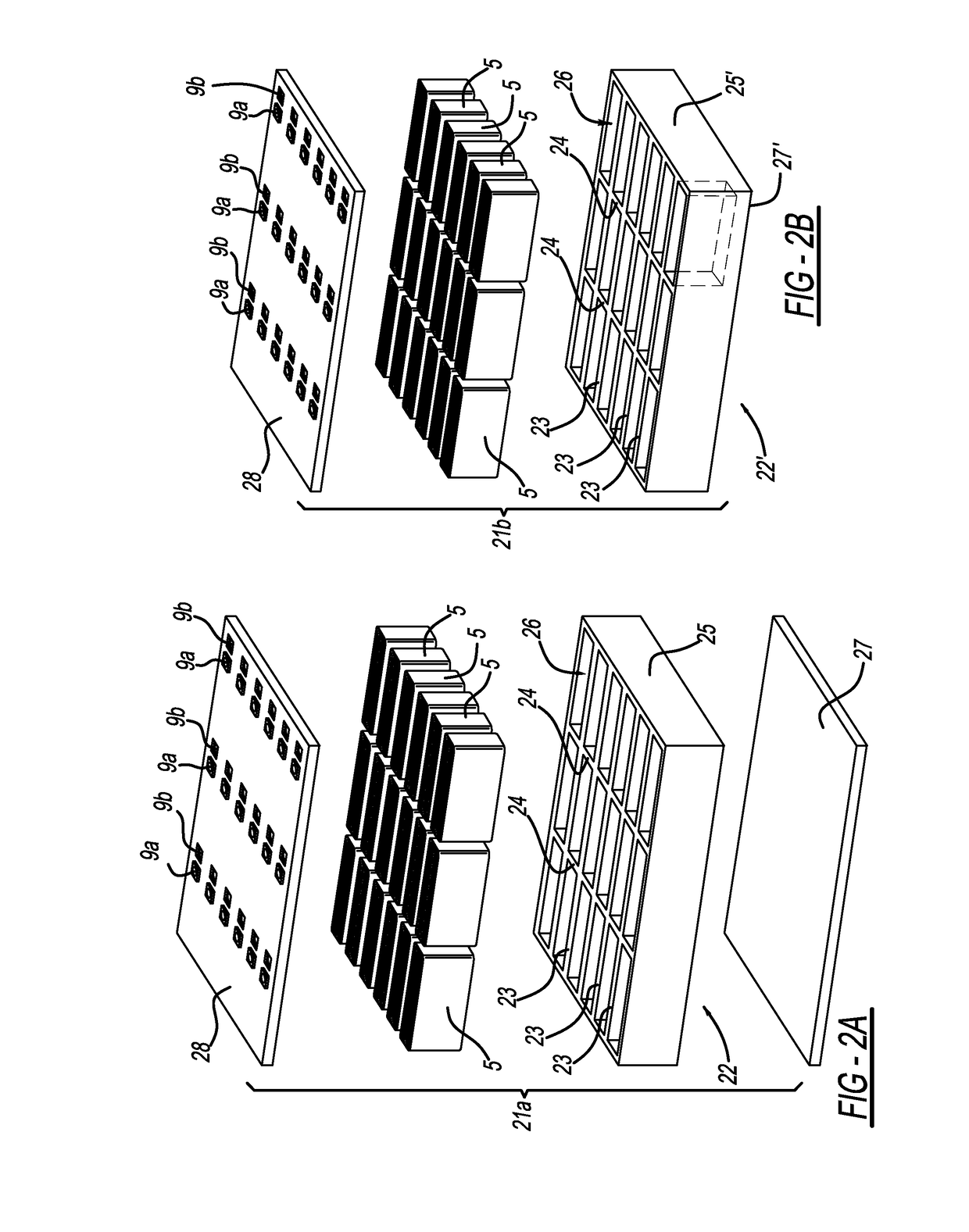

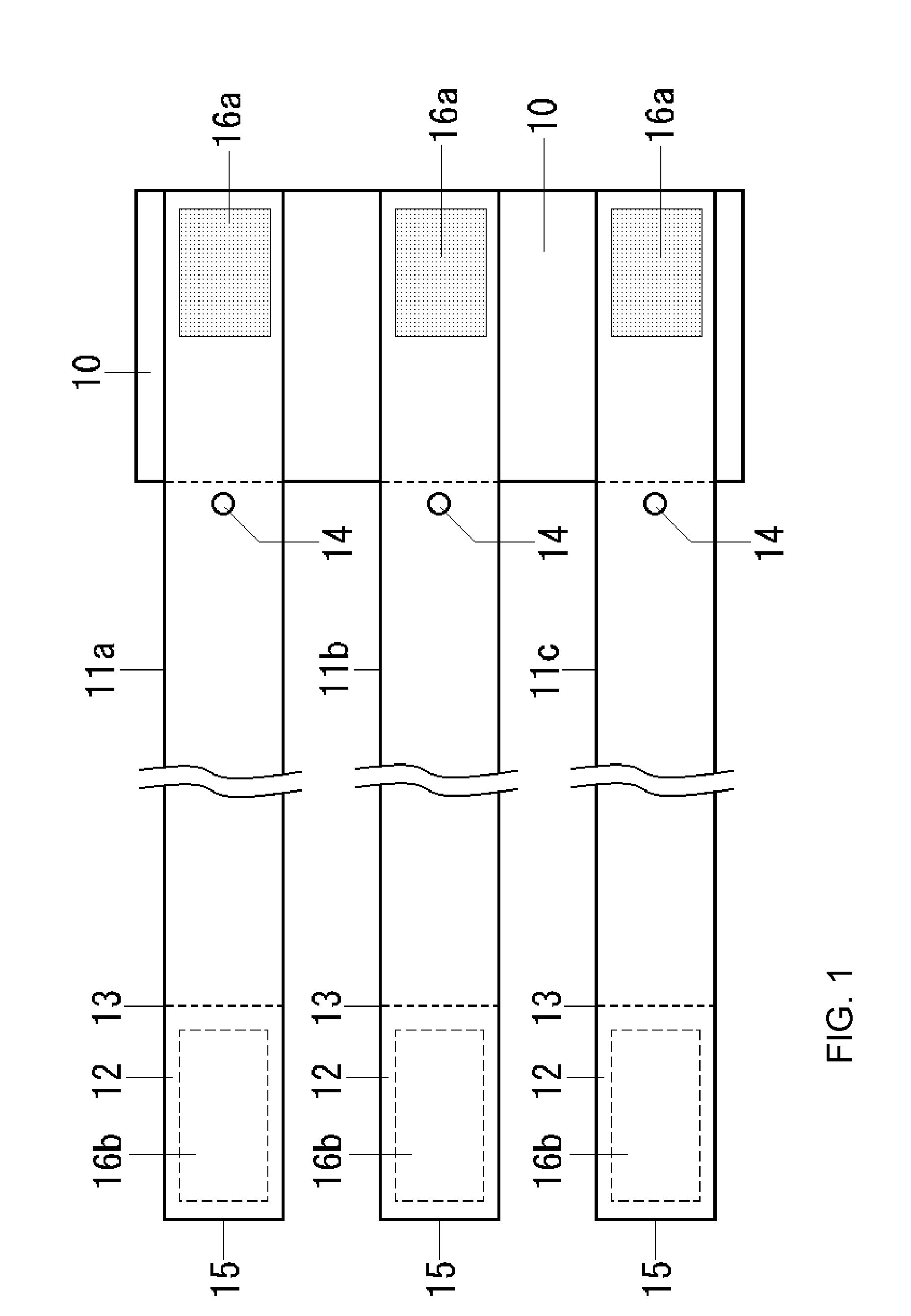

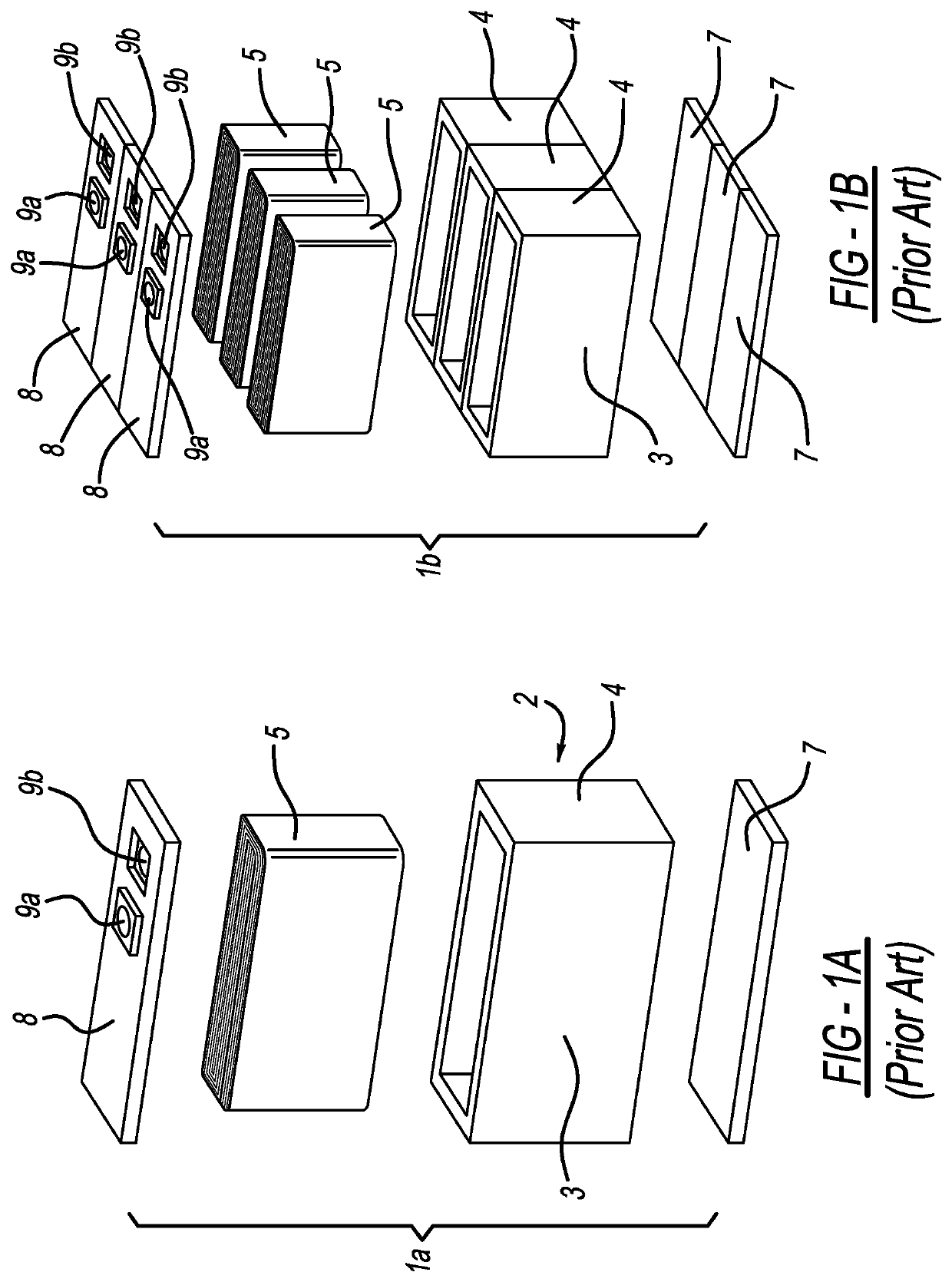

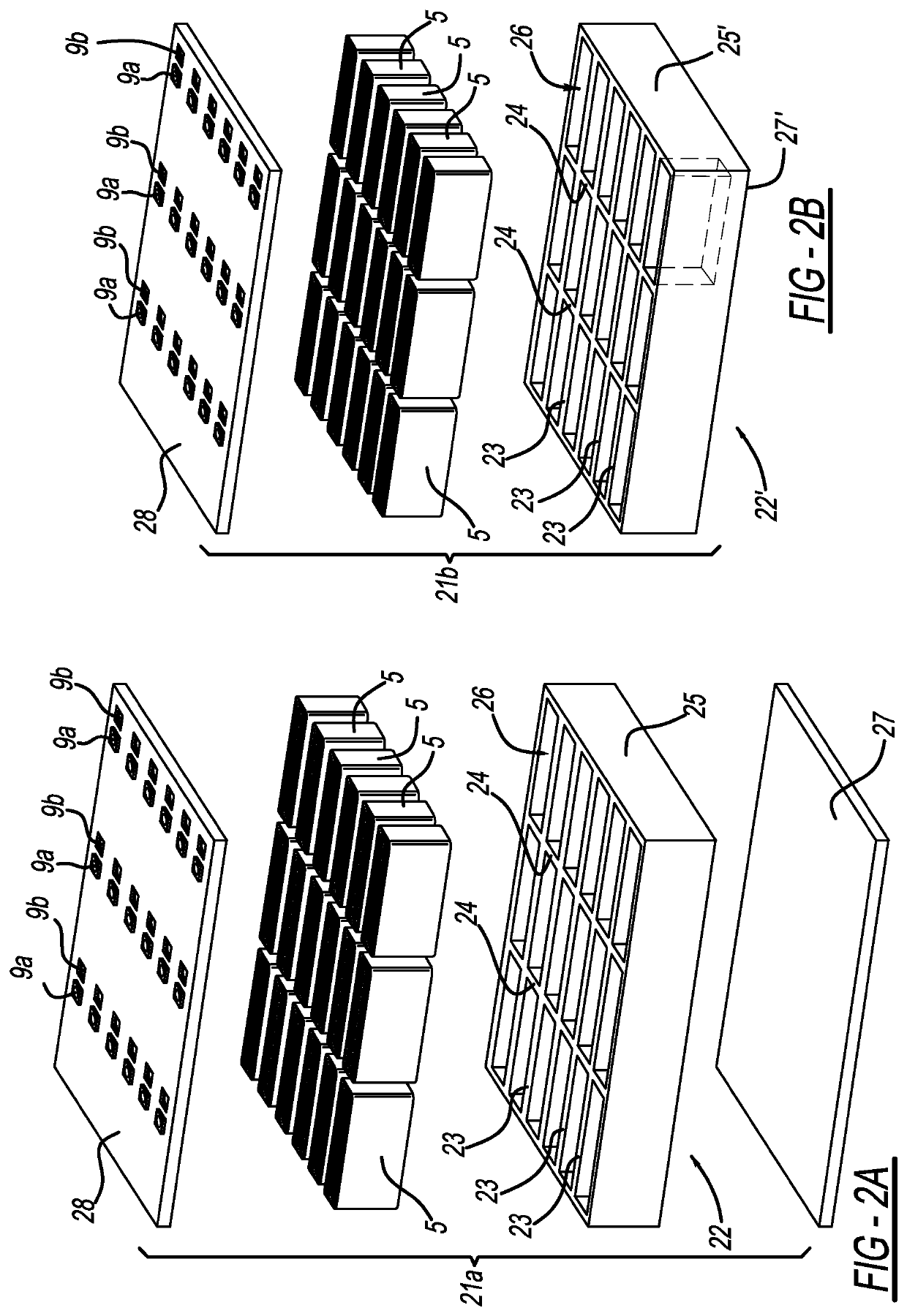

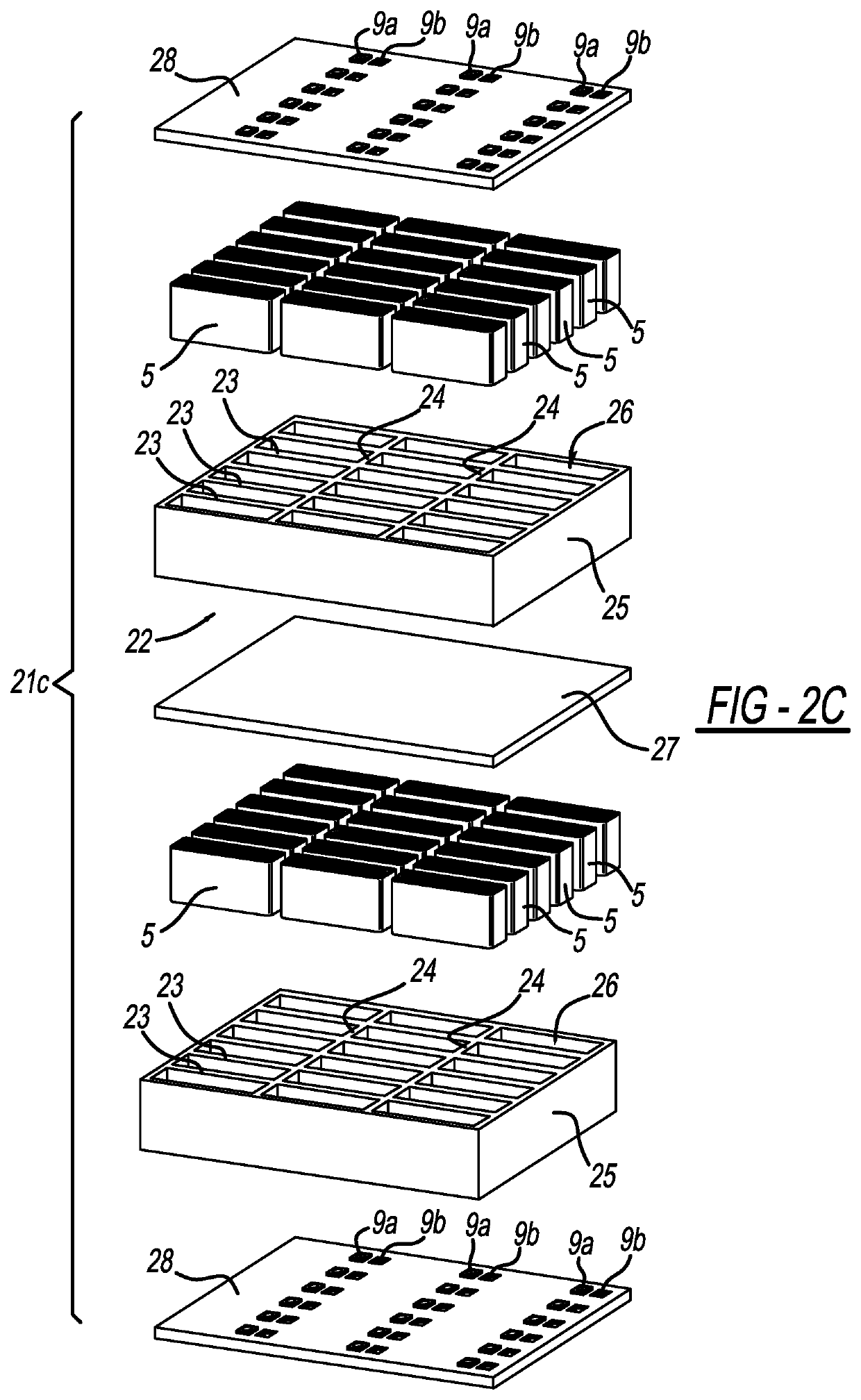

Multiple cell integrated casings

ActiveUS20170229683A1Weight saveSize/volume saveFinal product manufactureSmall-sized cells cases/jacketsEngineeringCell wall

The disclosure provides a battery cell casing for holding a plurality of cell elements, each electrode structure in its own compartment. The disclosed casing eliminates the need for some individual cell walls and replaces them with shared wall partitions.

Owner:FORD GLOBAL TECH LLC

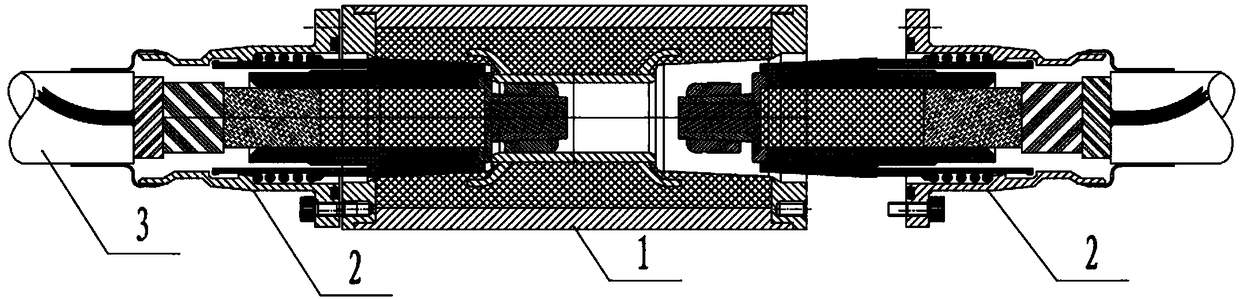

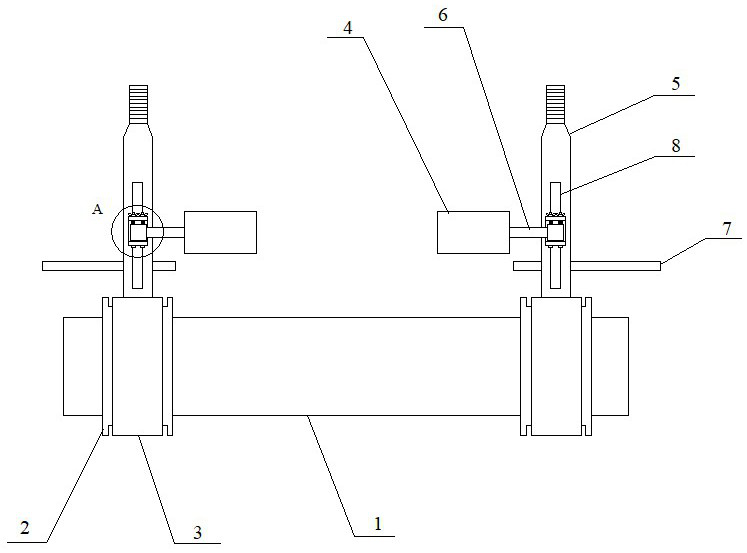

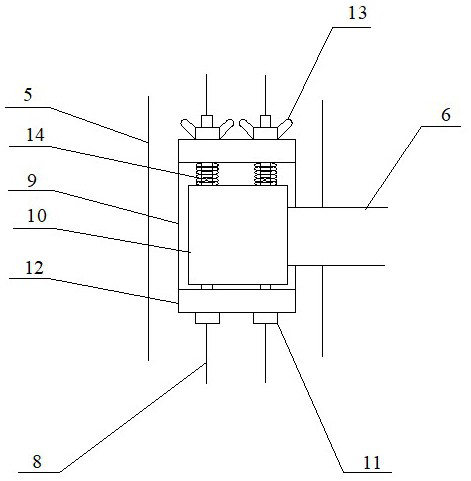

Quick connector device for flexible medium-voltage cable

PendingCN108649353AFirmly connectedFast connectionSecuring/insulating coupling contact membersCoupling contact membersWorking environmentPigtail

The invention discloses a quick connector device for a flexible medium-voltage cable. The device comprises a middle socket and two cable terminal plugs, wherein one ends of the two cable terminal plugs are respectively connected to the ends of the two cables, and the other ends of the two cable terminal plugs are detachably connected to the two ends of the middle socket respectively. According tothe quick connector device, through the two cable terminal sockets and the middle socket, a standardized cable connector is achieved, and a connection between a ring main unit and the cable becomes very convenient and efficient; compared with a traditional copper pigtail connection mode, the connection speed of the connector device is increased by tens of times, a problem that the connection efficiency is low in the traditional mode is effectively solved, the on-site rapid connection is realized, the all-weather working environment is adapted, the efficiency of installation and power transmission can be effectively improved, a user complaint rate can be reduced, the connector is normalized, and the device adapts to connections of the cables of different manufacturers and is easy to installand convenient to match.

Owner:GUIZHOU POWER GRID CO LTD

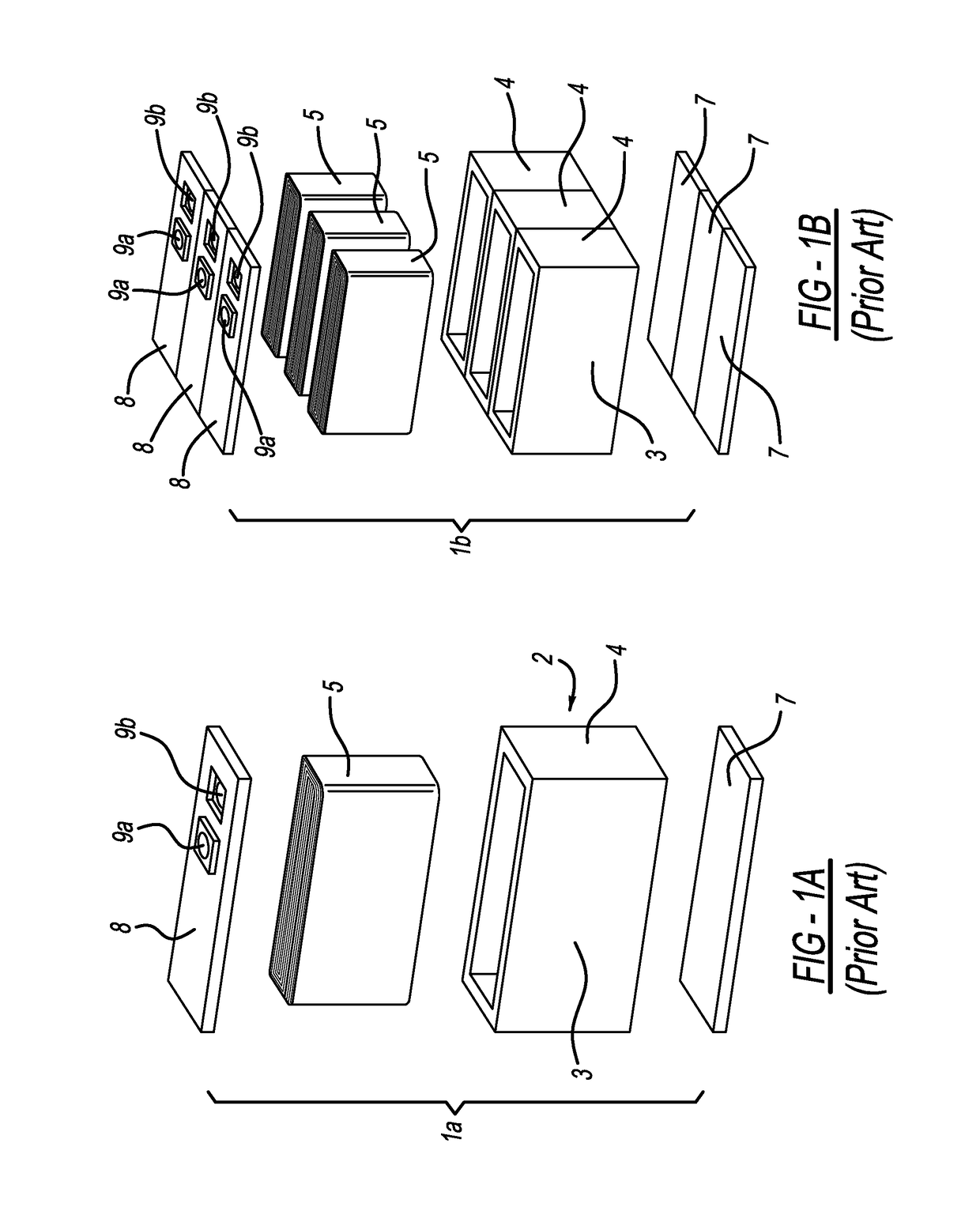

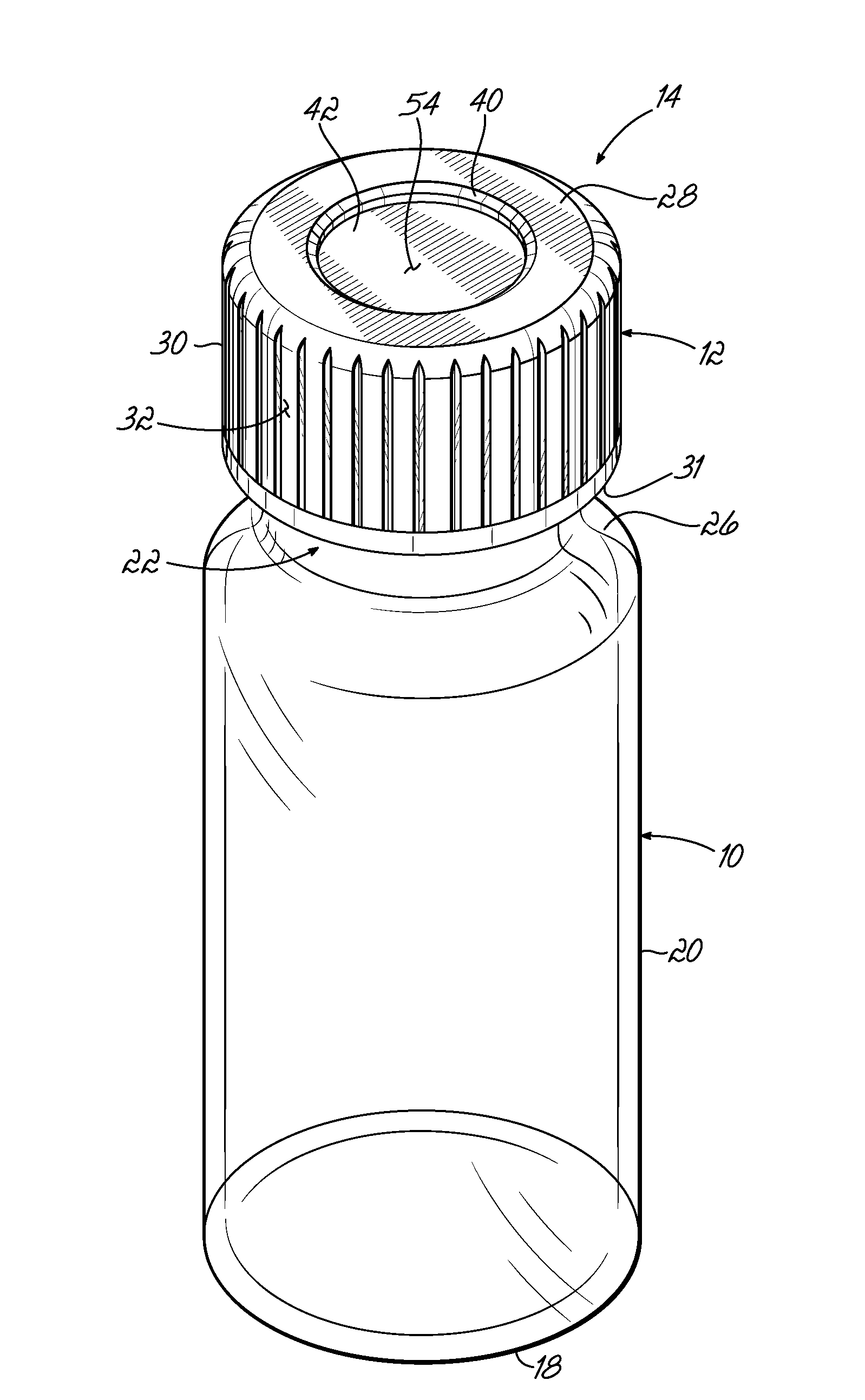

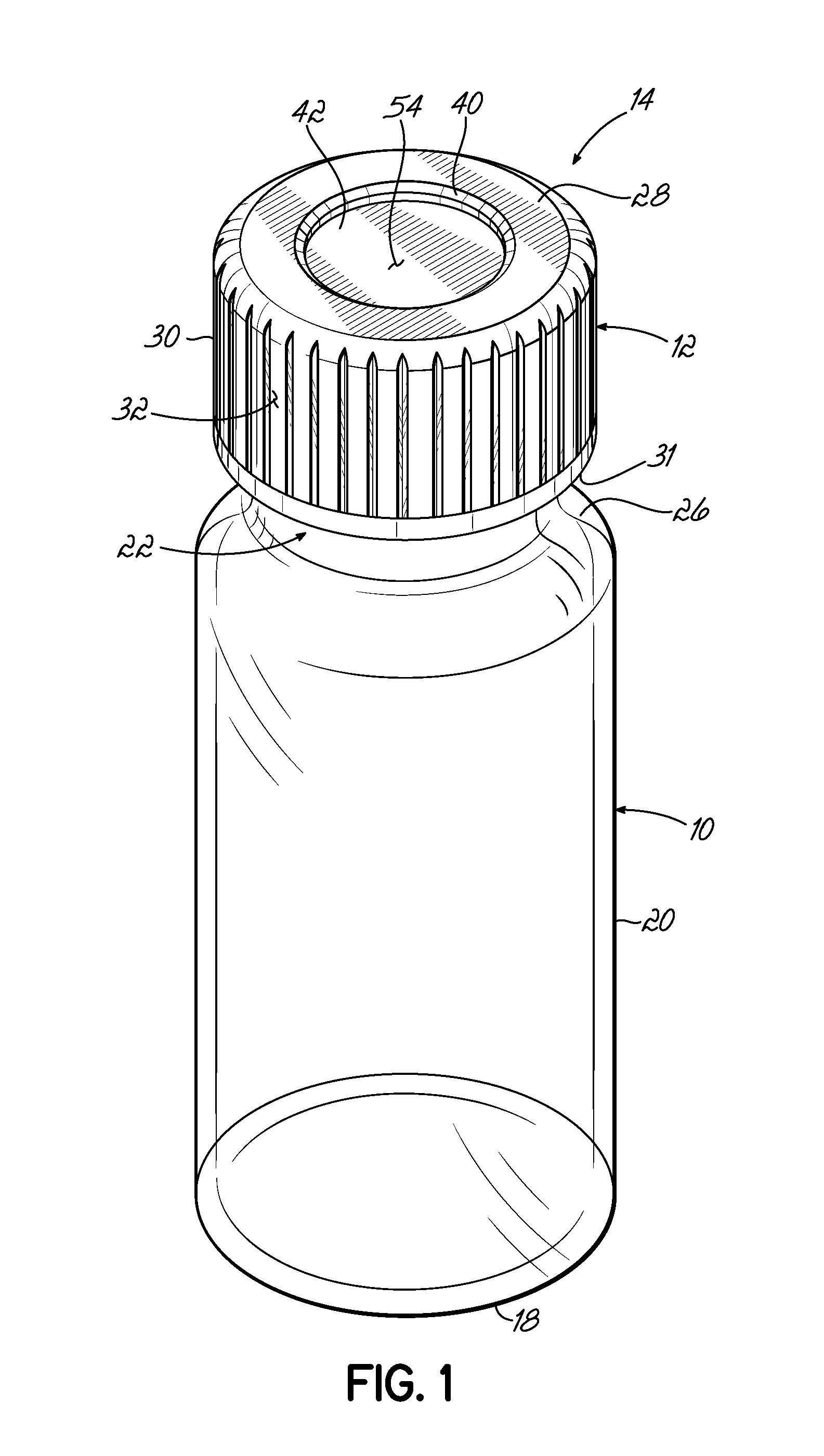

Over-torque resistant vial

ActiveUS20130058844A1Reduce tiltAvoid over-tighteningClosure capsLaboratory glasswaresMechanical engineering

An over-torque resistant vial and closure assembly includes a vial having an outwardly projecting rib that cooperates with a stop surface provided on a closure. When the closure is threadably coupled to the vial, the stop surface of the closure engages the outwardly projecting rib of the vial so as to prevent over-torquing of the closure onto the vial.

Owner:NAT SCI

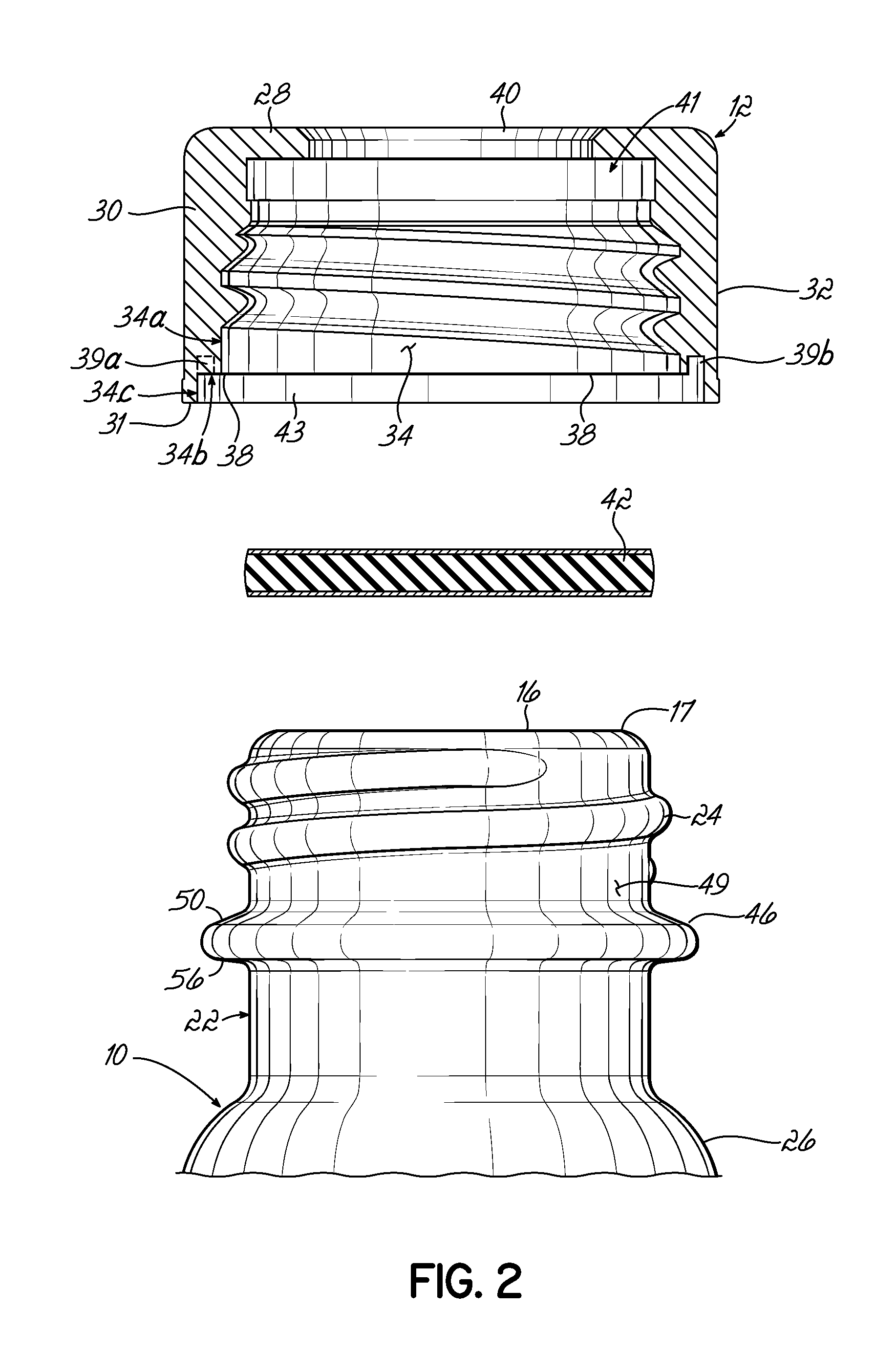

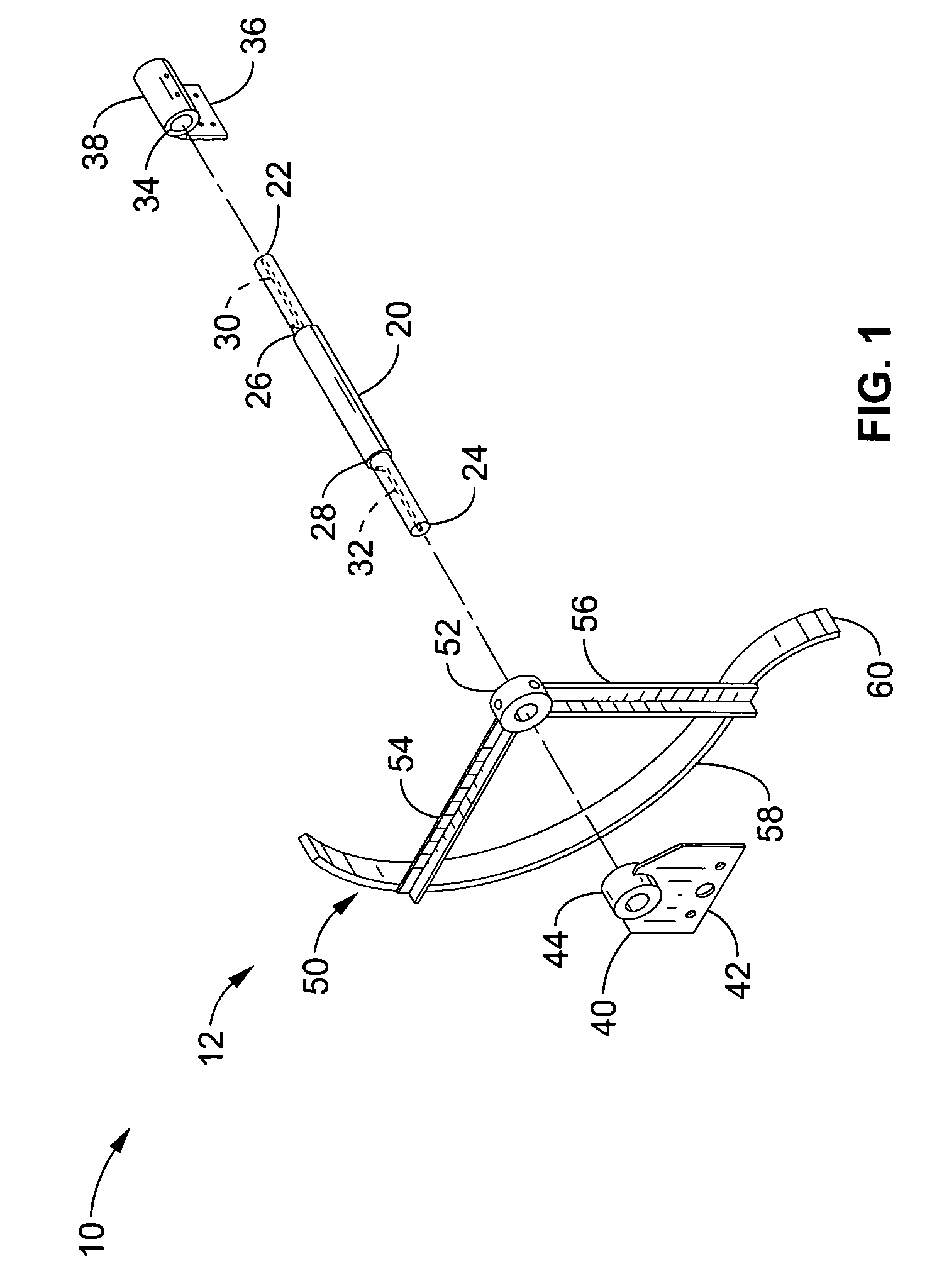

Plural parallel cuff for muscle training by pressurizing limb

ActiveUS20150297933A1Increase powerUniform compression forceMuscle exercising devicesThighMuscle training

A plural parallel cuff for muscle training is made to reinforce muscles of limbs while it is wound broad around the portion of an upper arm and / or a thigh with uniform and stable binding force for the light exercise training. Three cloth sleeve bags are sewn to a connection cloth spaced in parallel. Three short rubber bags are inserted into three cloth sleeve bags respectively. The rubber bags are connected each other with T-joints for air channel. A plug and a socket are used to connect the pneumatic pump detachably to the thin tube. The plural parallel cuff is wound around a limb and hook-and-loop fasteners are used to form loops by uniting both ends of each of the cloth sleeve bags. The rubber bags are inflated by a pneumatic pump for restricting the bloodstream and then an low intensity exercise is performed.

Owner:FUKUTA HIROJI

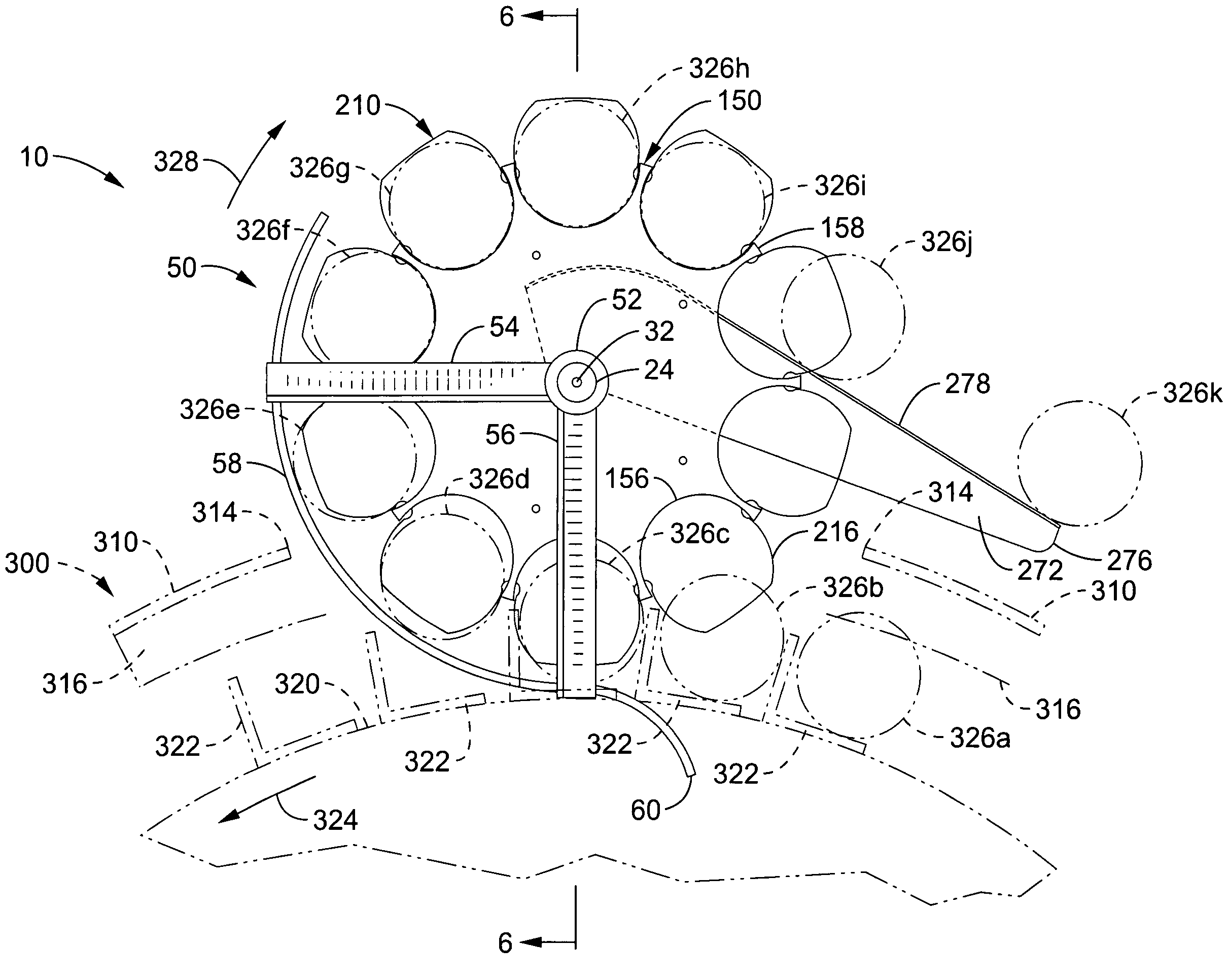

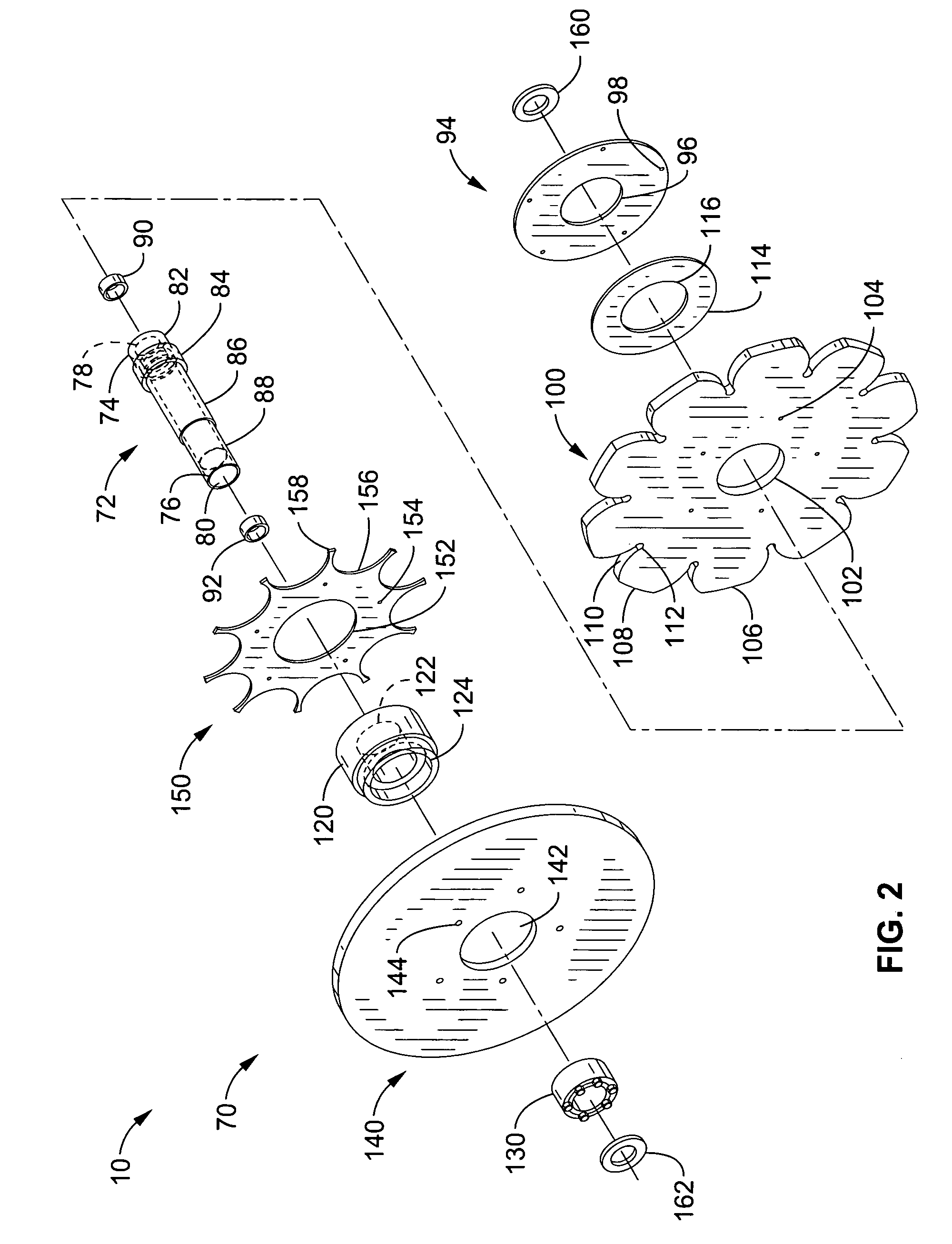

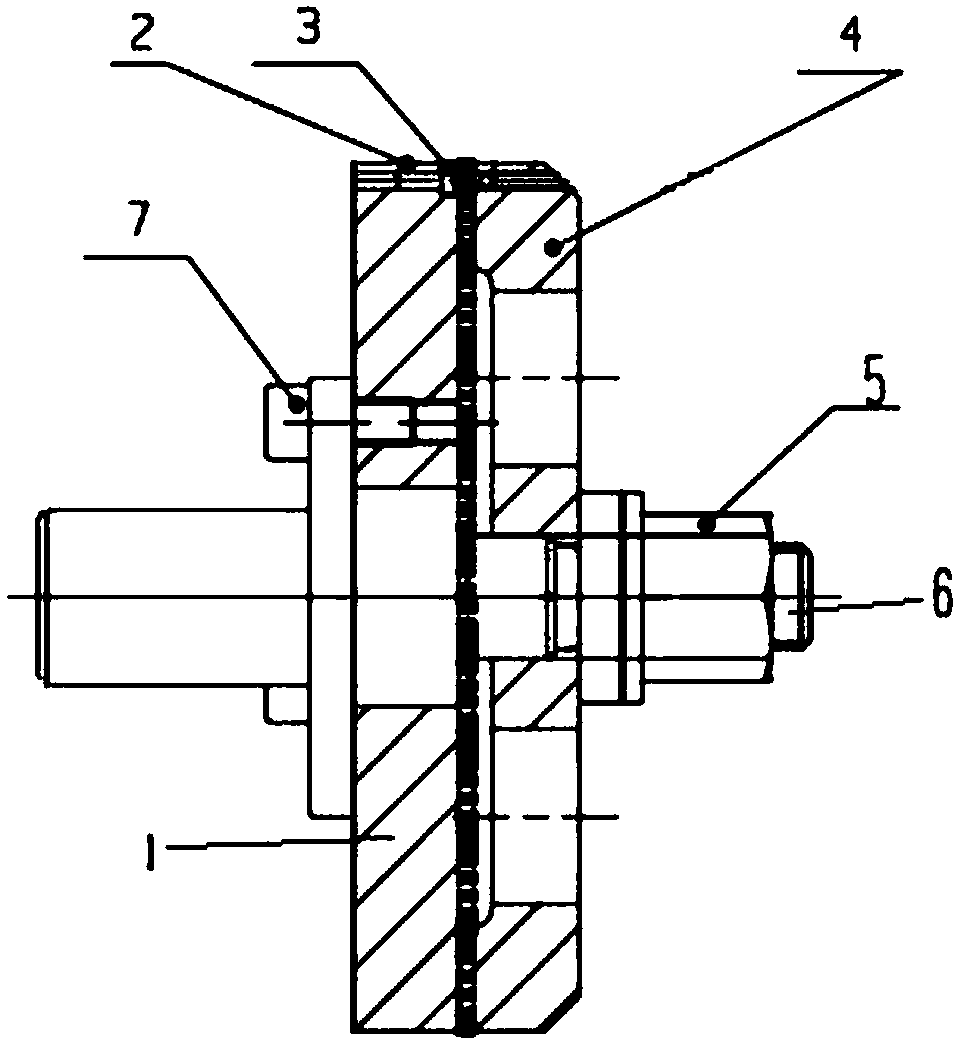

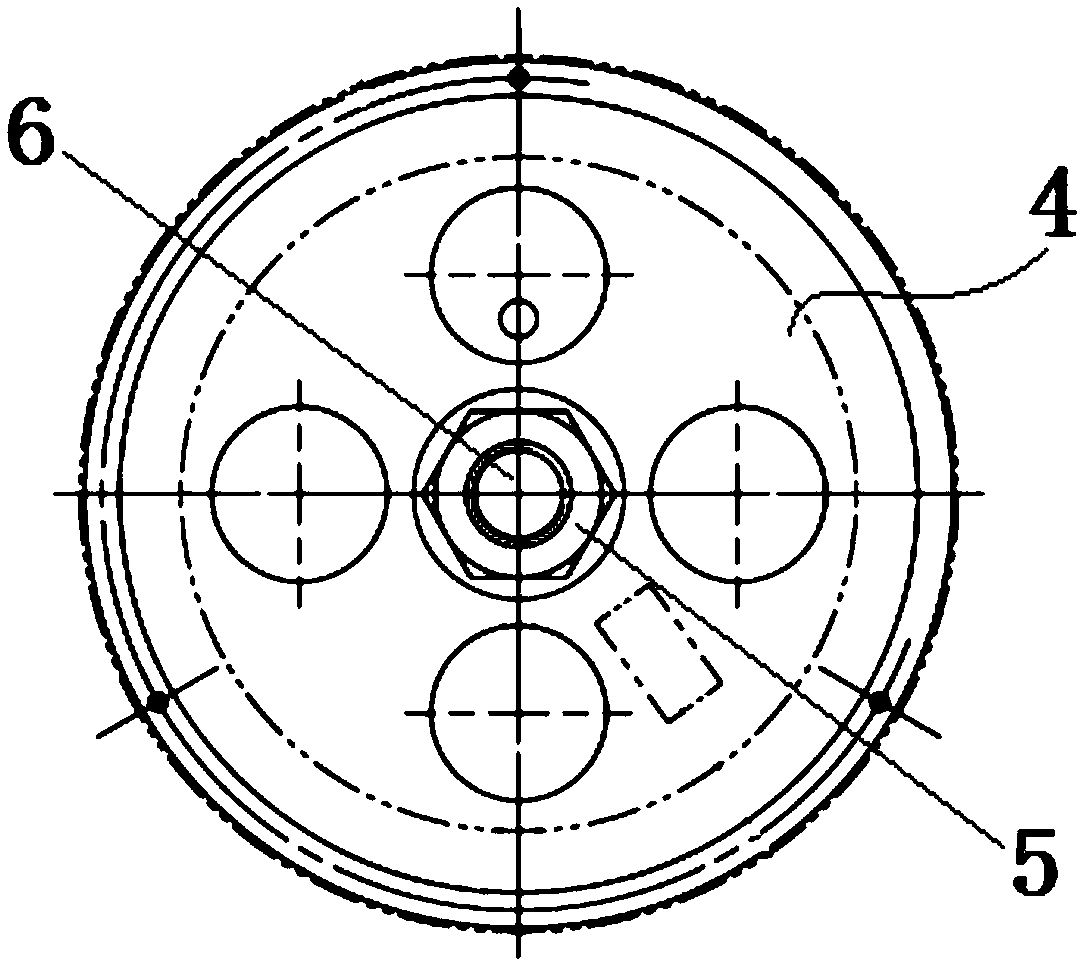

Can extractor apparatus

ActiveUS7284656B1Eliminate transferReduce scratchesFood preservationLavatory sanitoryEngineeringScratching

A can extractor for atmospheric rotary cookers and coolers has a clover wheel, a star wheel and a star wheel flange made of stainless steel. The clover wheel and star wheel are aligned and coupled to a sleeve rotating on a stationary shaft. The star wheel is coupled to the sleeve using an adjustable keyless hub / shaft locking device. The clover wheel and star wheel are spaced to accommodate bulging or deformed cans. A center discharge chute is supported on the rotating sleeve with a plastic bushing. Cans from the reel of a cooker / cooler are positioned with a can stripper between the star wheel and clover wheel while the reel rotates the clover wheel. The stainless steel components reduce scratching and eliminate transfer of rust to cans. A plastic clover wheel and a plastic star wheel flange are disclosed that do not scratch or transfer rust to the cans.

Owner:ALLIED MACHINE

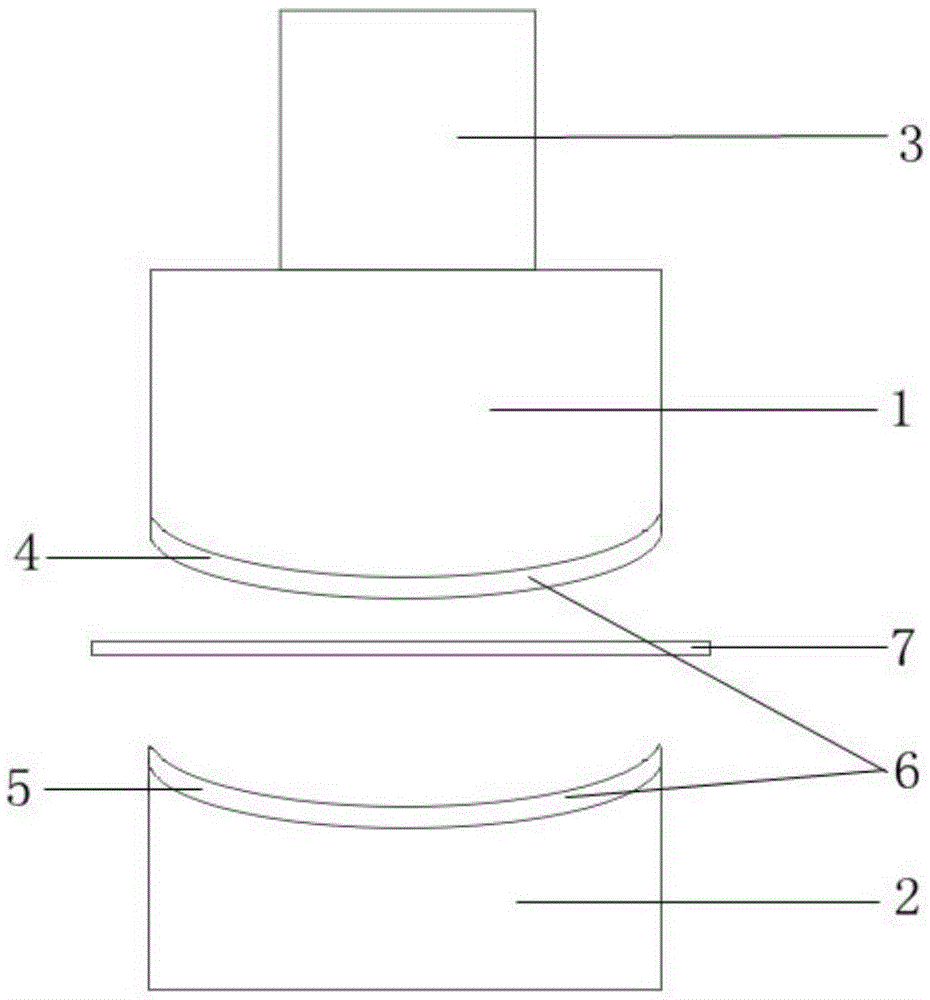

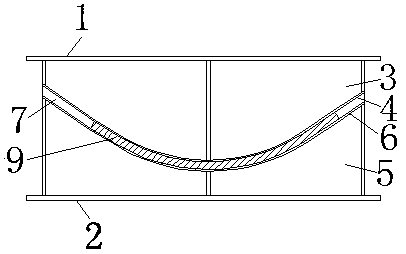

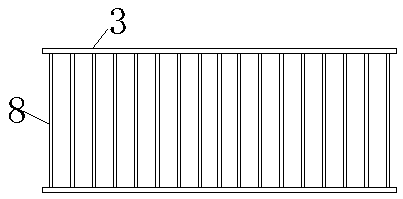

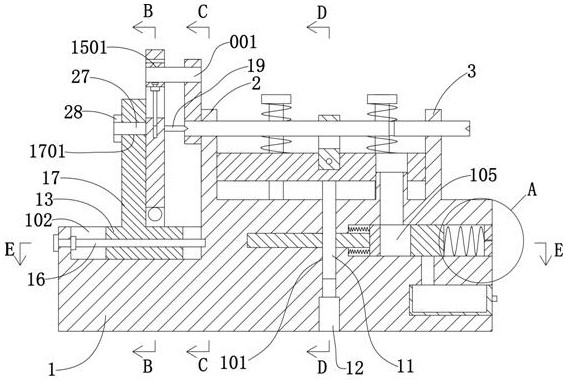

Light and efficient polarizing film bending manufacturing tool

The invention discloses a light and efficient polarizing film bending manufacturing tool, and relates to the field of film processing tool. The tool comprises an extrusion device, a fixing and moulding device, and a cylinder. The extrusion device is provided with an arc protruded extrusion device work surface. The fixing and moulding device is provided with a recessed groove that cooperates with the extrusion device work surface. The extrusion device work surface and work surface of the fixing and moulding device are both provided with a baked porcelain layer; the extrusion device is fixedly connected to the cylinder, the cylinder provides power to the extrusion device, and the extrusion device presses the fixing and moulding device so as to bend and mould a polarizing film. The provided tool is used to manufacture polarizing films and has the advantages that the flatness and smoothness of the polarizing film are good, the structure is simple, the processing and manufacturing are easy, and the polarizing film can be produced massively.

Owner:DONGXING HUAHONG OPTICAL TECH

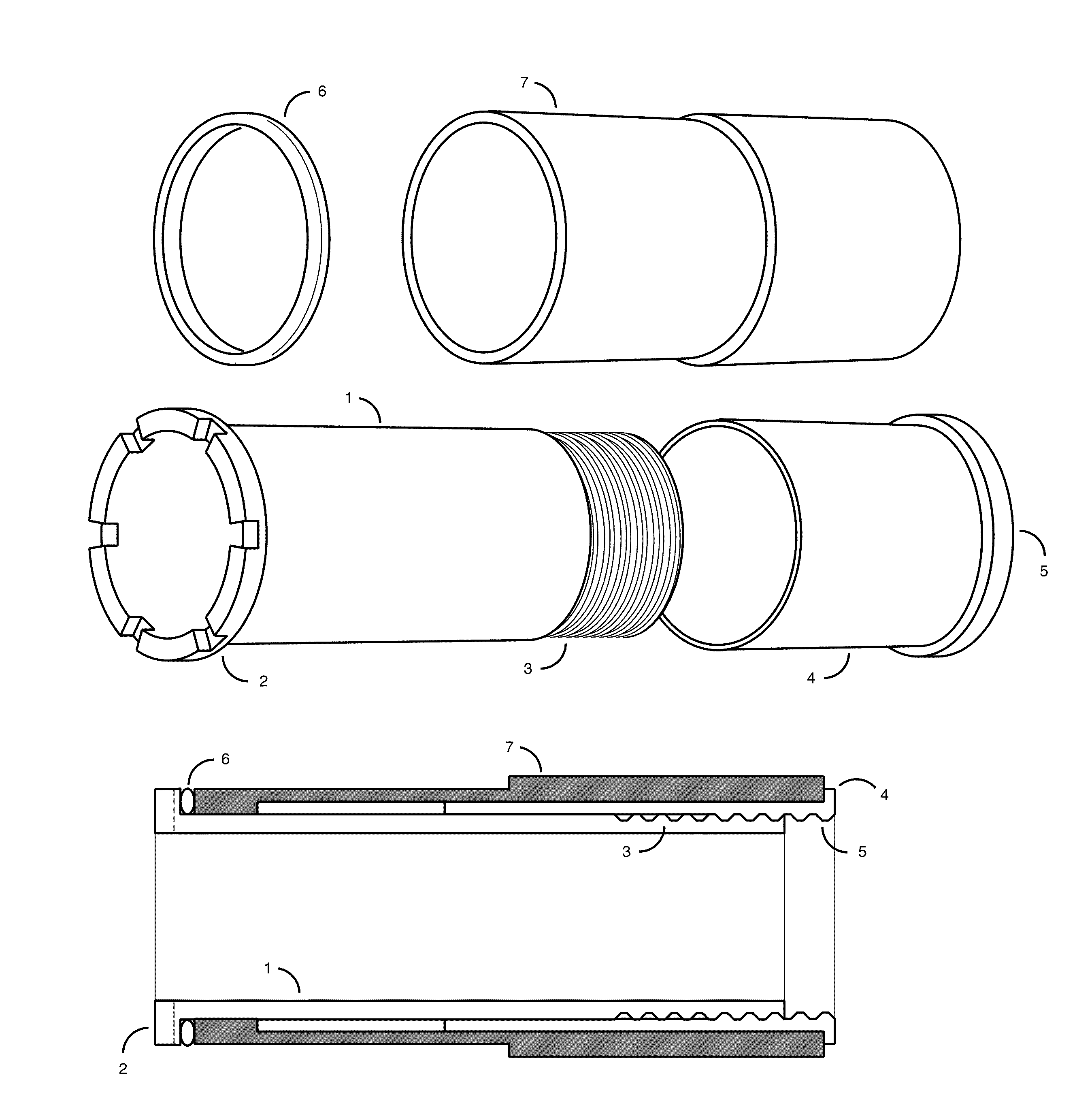

Sealable drain pipe coupling

ActiveUS20110084475A1Reduces installation timeReduce installation costSleeve/socket jointsWater closetsBiomedical engineeringDrain tube

The present invention relates to an apparatus which forms a sealed joint between two pipes, particularly but not limited to roofing drain pipes. This apparatus includes a cylindrical body made of rubber or similar material that grips and seals two pipes when it is axially compressed by two halves of an articulated housing as they move towards each other. The two half bodies of the articulated housing are connected together by means of integrated threads such that when one body is rotated in one direction, the bodies move towards each other, thereby reducing the overall length of the housing, and compressing / deforming the rubber seal. The housing also provides a means of rotating / tightening the apparatus by providing a mating head for an appropriately shaped tightening tool.

Owner:ABBASI ABDUL LATIF +1

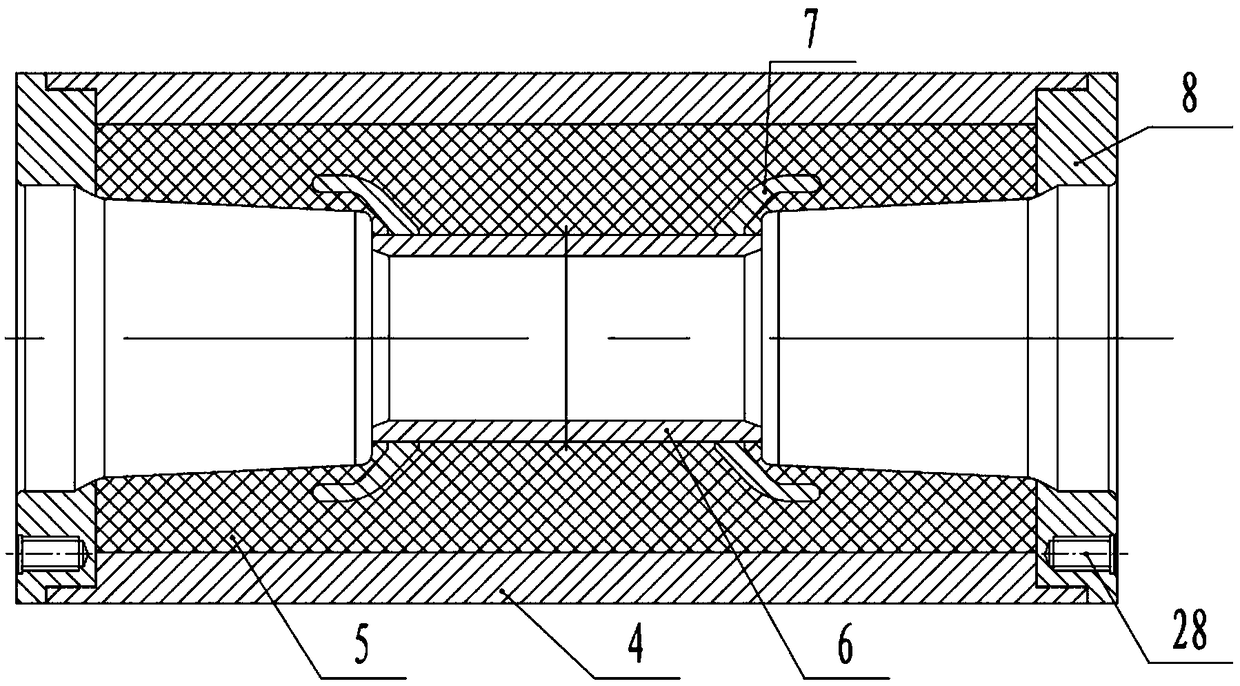

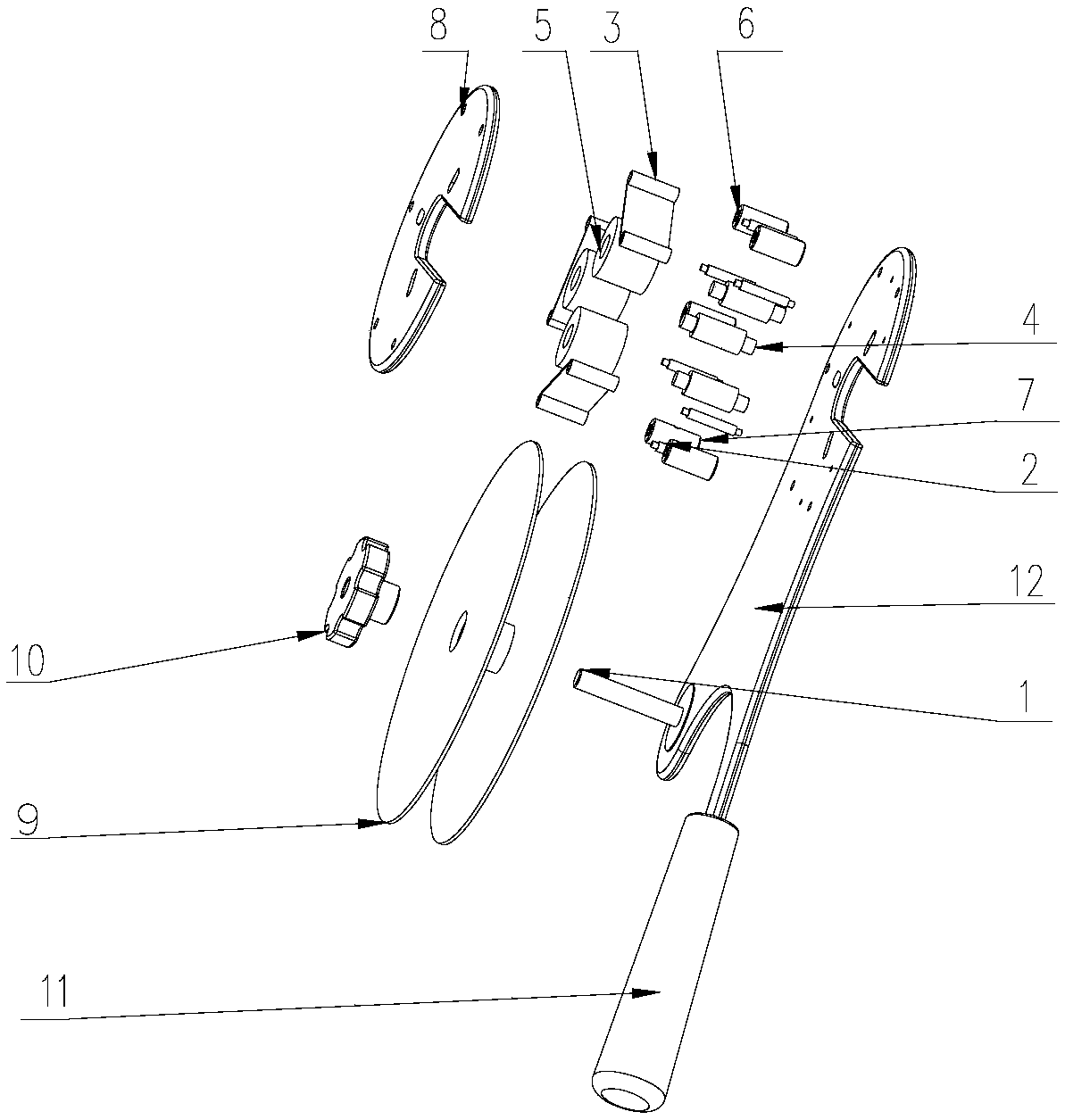

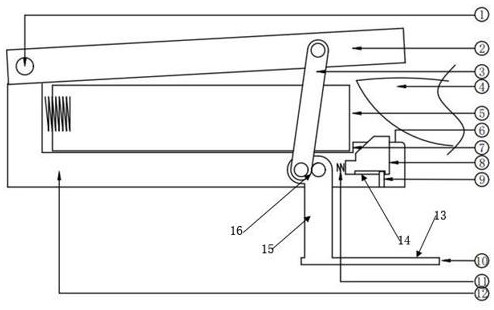

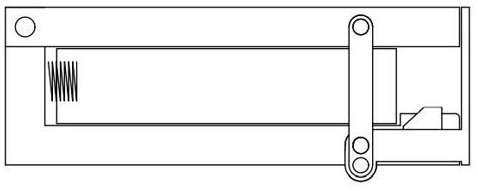

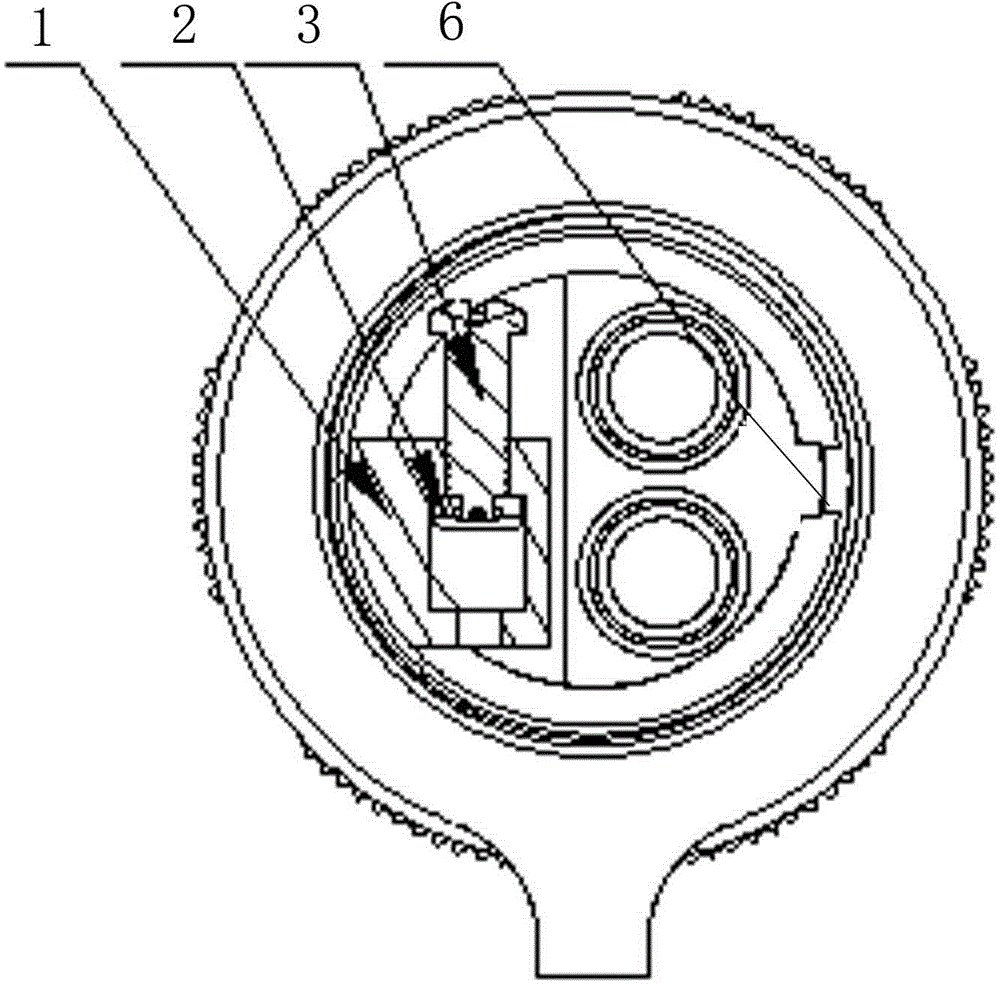

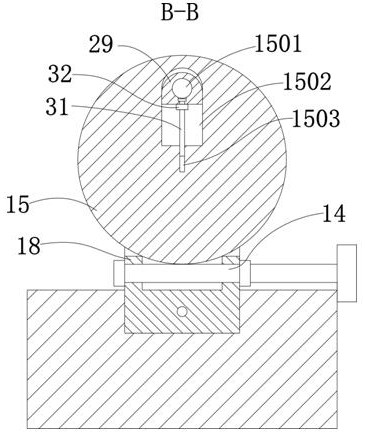

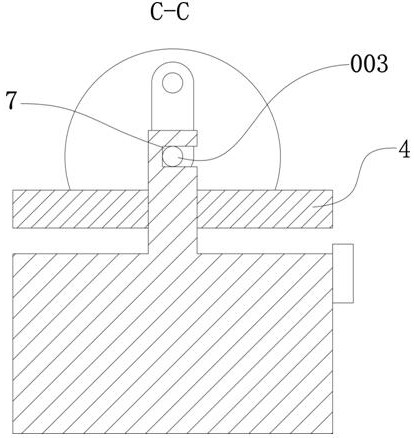

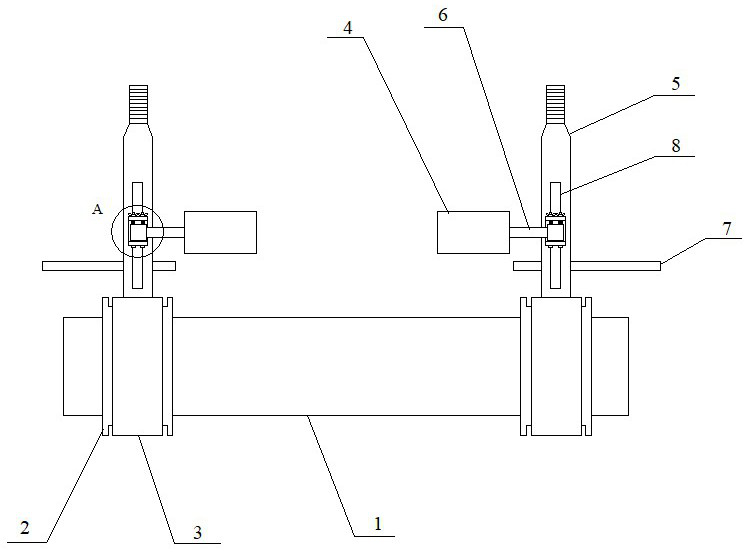

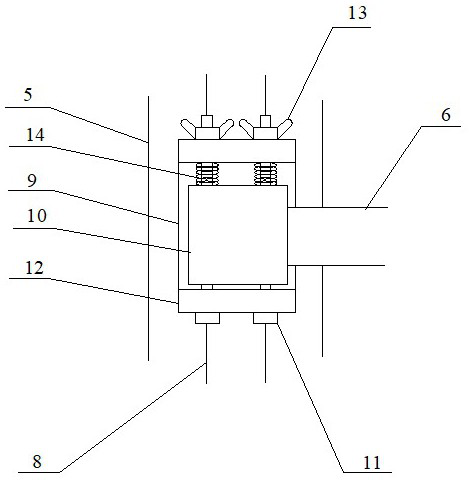

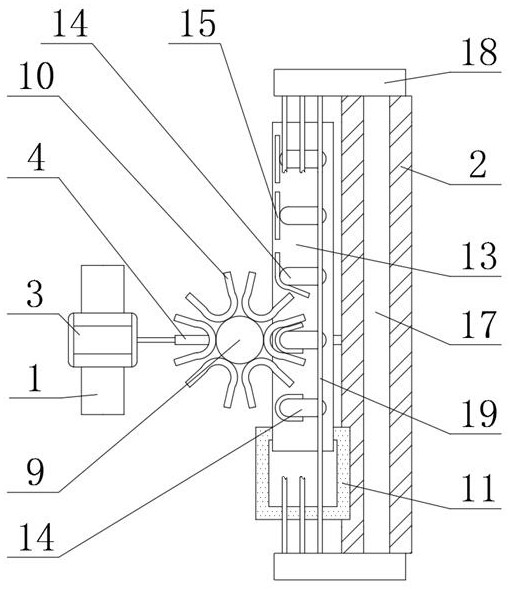

A monofilament winder for repairing transmission line conductors and its application method

ActiveCN106972405BUniform compression forceProcess levelingApparatus for overhead lines/cablesEngineeringMechanical engineering

The invention relates to a single-filament winder used for repairing wire of a power transmission line and a use method of the single-filament winder, and belongs to the technical field of power transmission lines. The winder comprises a handle, a base plate and a cover plate. One end of the base plate is connected with the handle and the other end is equipped with a U-shaped groove opening. A fixed shaft, three groups of rubber roller shaft, a spring sheet shaft and a positioning shaft are arranged around the U-shaped groove opening. Three groups of spring sheets are fixed on the spring sheet shaft. Three groups of rubber rollers are fixed on the rubber roller shaft. The fixed shaft, the spring sheet shaft and the positioning shaft are fixed by the cover plate through bolts. A wire disc shaft is arranged on the base plate. A wire disc is installed on the wire disc shaft and is fixed by a force resisting bolt. A repair point of the wire is clamped by the three rubber rollers, and after a single-filament aluminum wire is threaded in the wire disc through the positioning shaft, the winder is rotated to move forward in a rotary manner, so the repair point of the wire is repaired. The whole technique is free of gaps and kept flat, so a good use effect is achieved.

Owner:GUIZHOU POWER GRID CO LTD

Multiple cell integrated casings

ActiveUS10686166B2Easy alignmentReduce weightFinal product manufactureSmall-sized cells cases/jacketsEngineeringCell wall

The disclosure provides a battery cell casing for holding a plurality of cell elements, each electrode structure in its own compartment. The disclosed casing eliminates the need for some individual cell walls and replaces them with shared wall partitions.

Owner:FORD GLOBAL TECH LLC

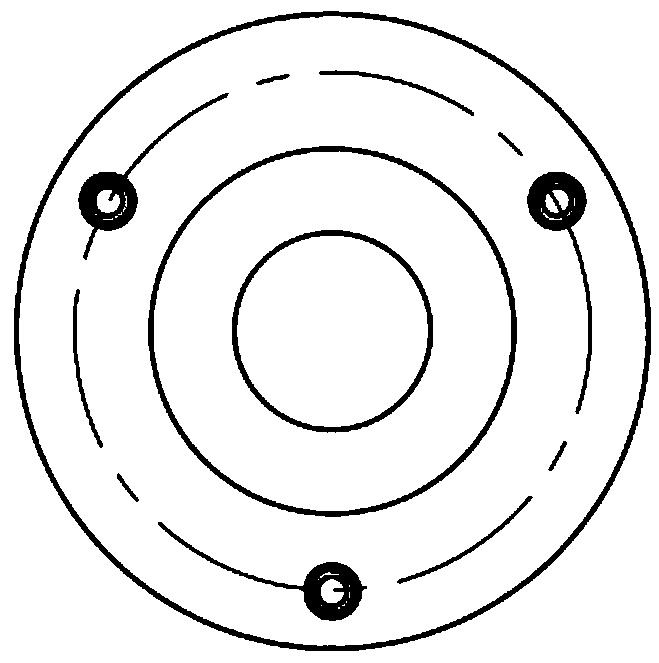

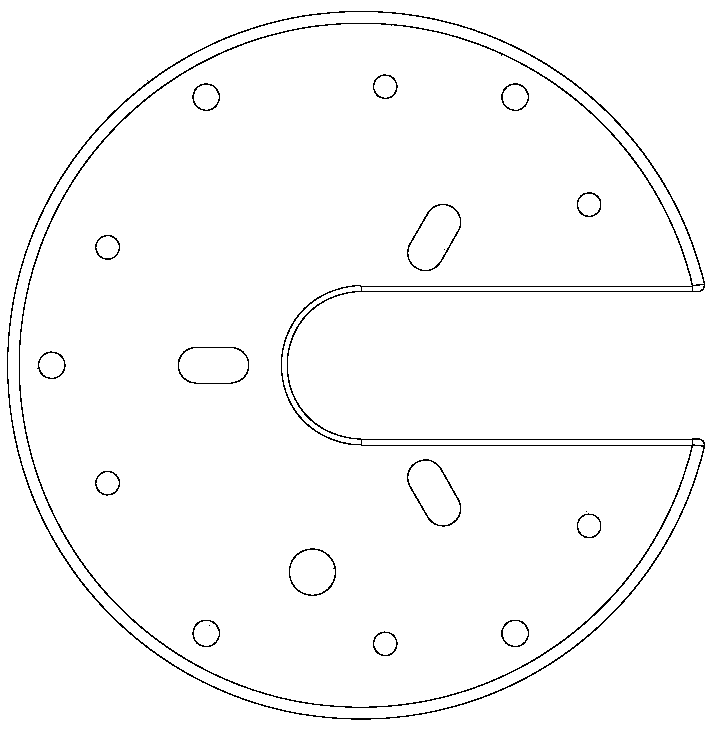

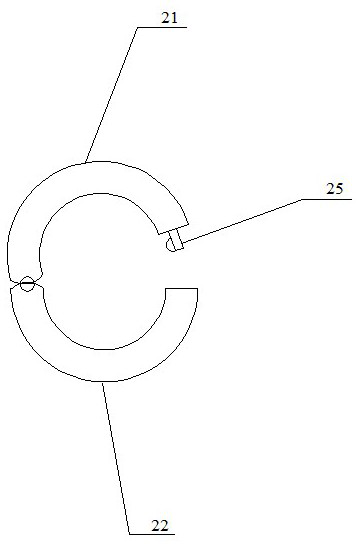

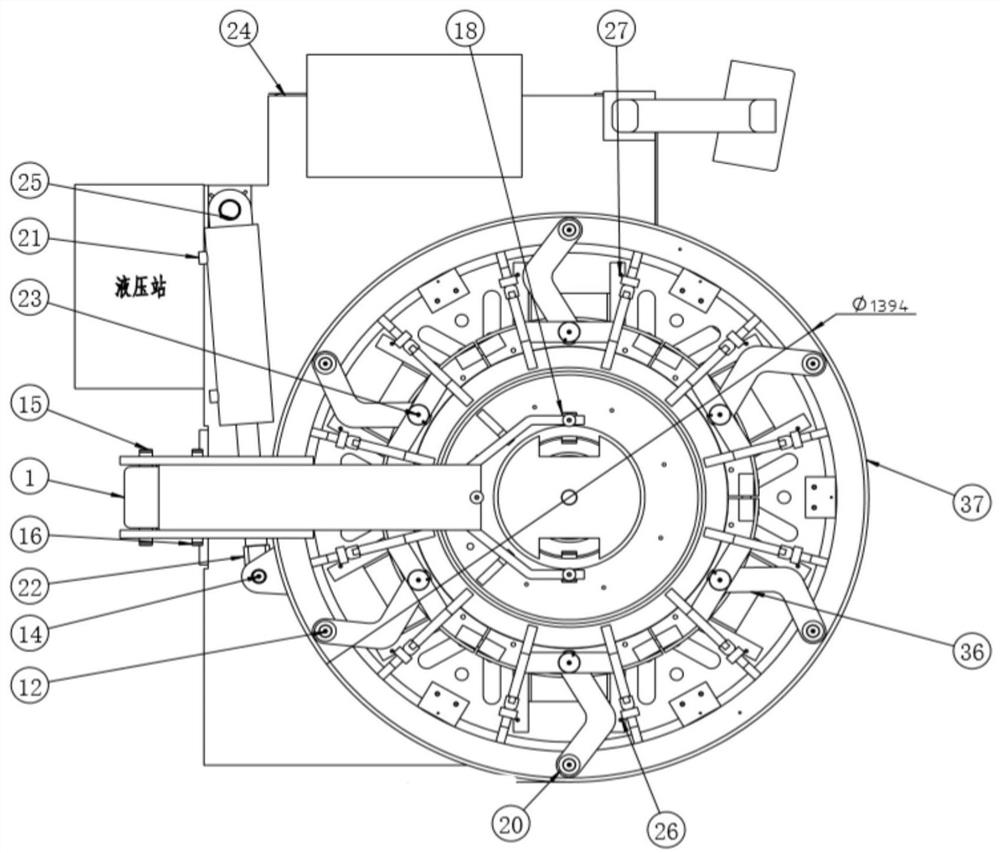

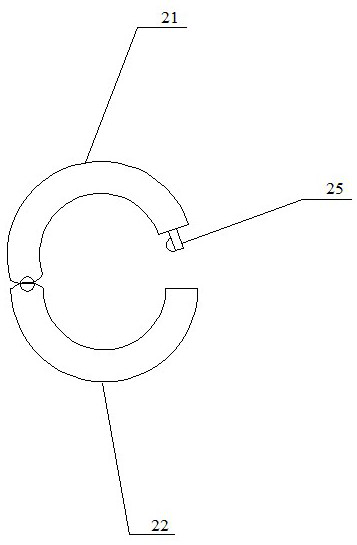

Mounting tool and mounting method for flexible ring-wrapped capacitive sensor

ActiveCN113319785AGuaranteed detection accuracyEasy to operateMetal-working hand toolsEngineeringStructural engineering

The invention discloses a mounting tool and a mounting method for a flexible ring-wrapped capacitive sensor, and belongs to the technical field of cable joint detection equipment mounting. The mounting tool comprises two fixing rings arranged on the two sides of a cable joint, and a press fitting mechanism rotationally connected with the fixing rings, wherein the press fitting mechanism comprises a ring sleeve, a driving part and a press fitting wheel, the ring sleeve is arranged on the outer side of the fixing ring in a sleeving mode, the driving part is arranged on the ring sleeve, and the press fitting wheel is arranged on the driving part and used for wrapping the cable connector with the flexible ring-wrapped capacitive sensor. The mounting tool and the mounting method are adopted for standard operation, so that the flexible capacitive sensor is not affected by dirt, uneven stress and other conditions, and the form and the shielding effect of the mounted metal shielding net are not affected, and therefore, the detection accuracy of the capacitive sensor is ensured; in addition, the mounting of the flexible capacitive sensor and the metal shielding net can be completed in sequence, the operation is convenient, and the efficiency is high.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

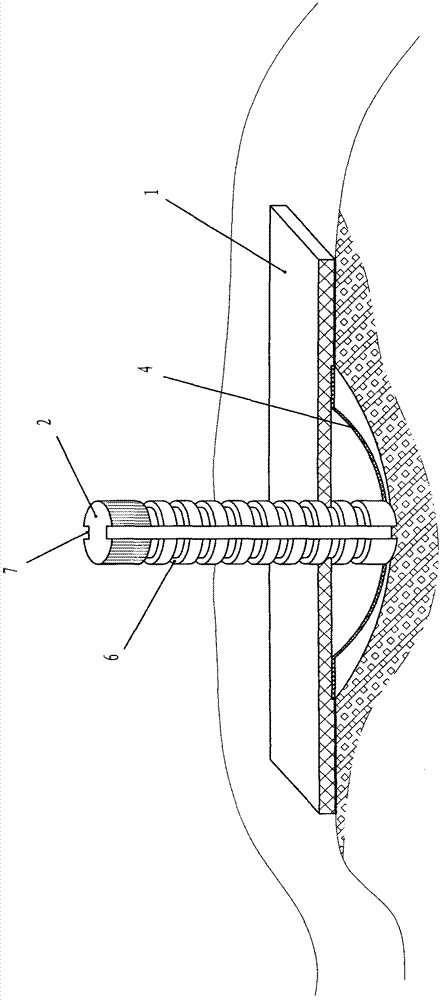

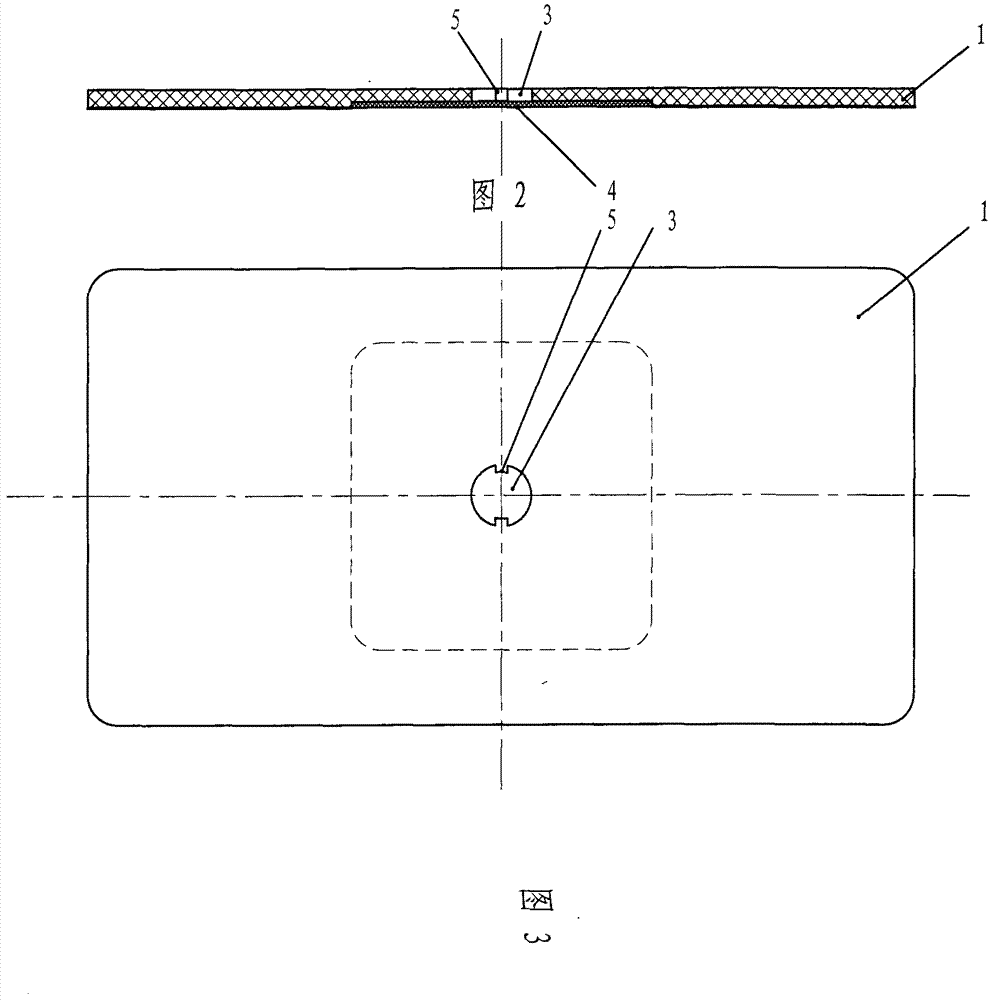

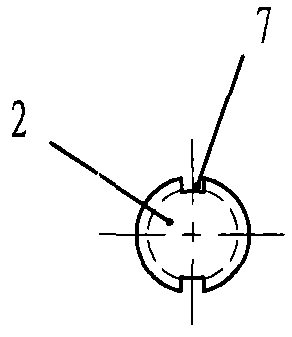

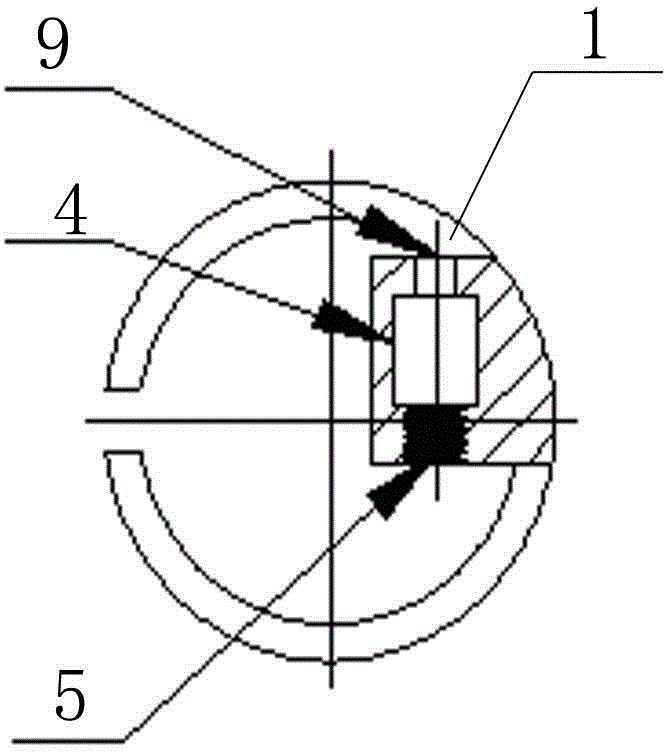

Body surface haemostat

A body surface haemostat is characterized by comprising a rigid fixing piece (1) and a limiting rod (2), a limiting hole (3) is arranged in the middle of the fixing piece (1), the limiting rod(2) can be inserted into the limiting hole (3) to form snapping connection limiting, the ventral surface of the fixing piece (1) is coated with medical adhesive or is provided with a sucker, and the inside surface of the limiting hole (3) is covered with a wound protective layer (4). The body surface haemostat has the advantages that the limiting rod is inserted into the limiting hole and is snapped in the fixing piece to achieve the compression hemostasis on a wound, and accordingly using easiness and safety can be obtained; the limiting rod and the fixing piece are separated, not only the processing easiness is facilitated, but also the fixing piece can be reused, and therefore energy saving and environmental friendliness are obtained; and the limiting rod is provided with two or more limiting rod annular grooves to enable the limiting hole and the limiting rod to form limiting among different limiting rod annular grooves, so that a user can apply pressing forces in different strength according to the wound situation of a patient.

Owner:孙春云

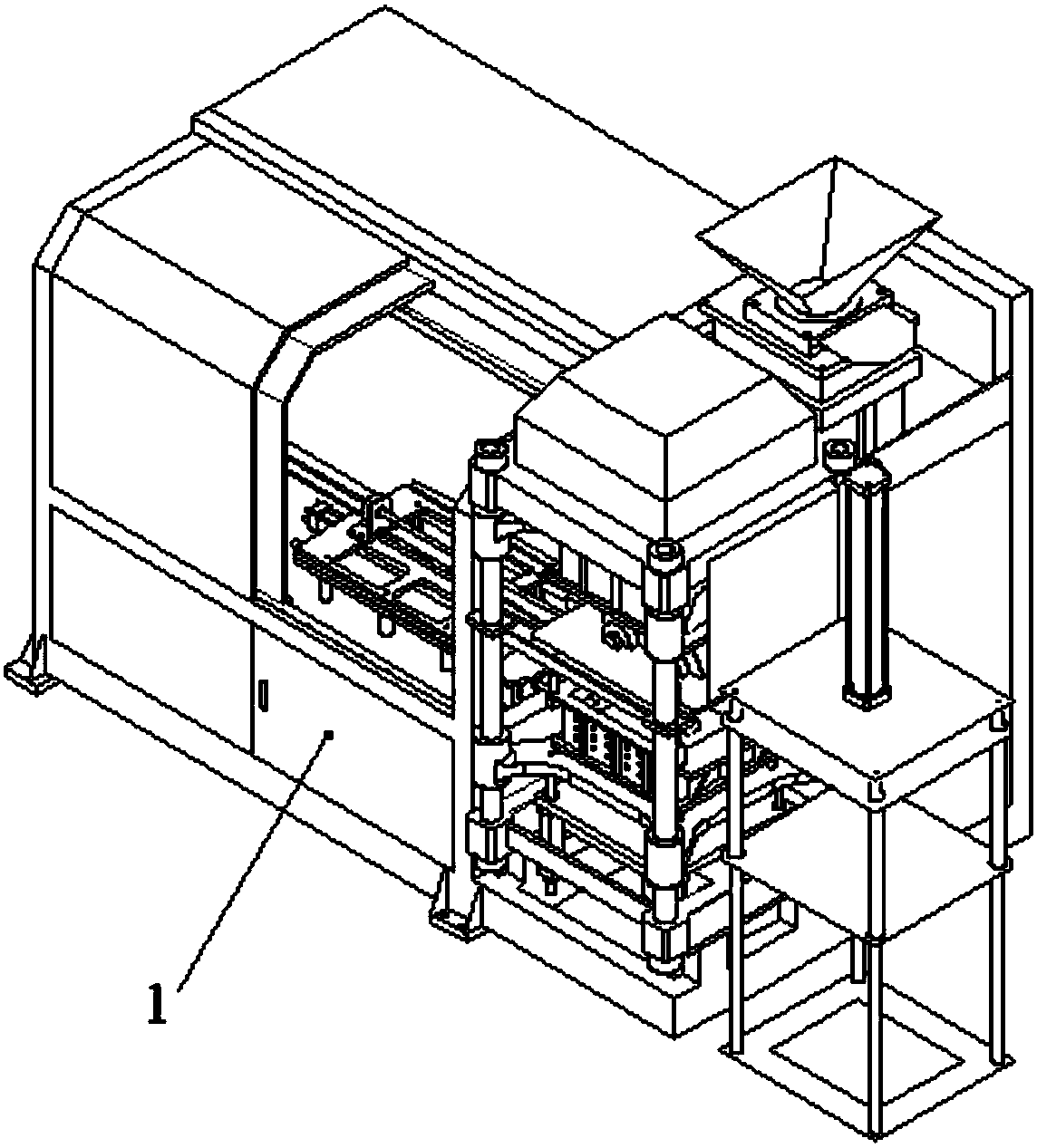

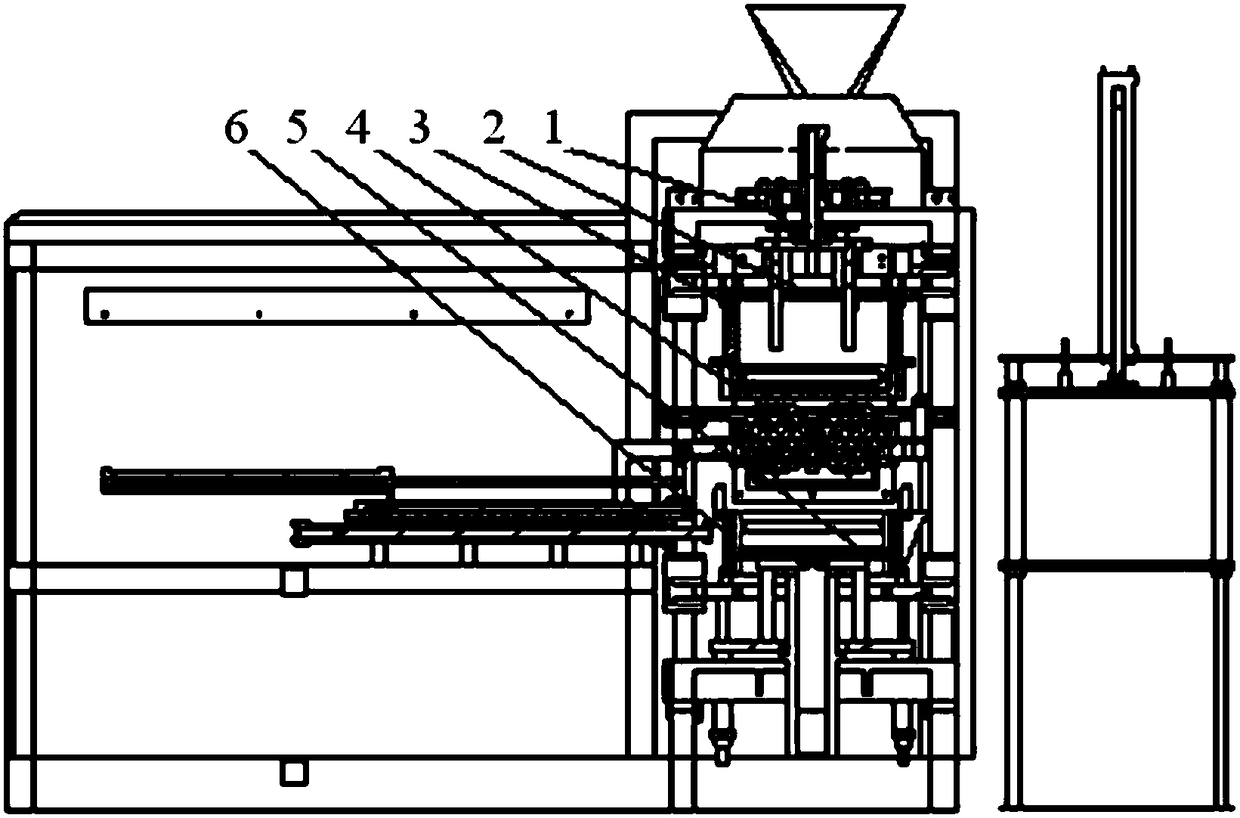

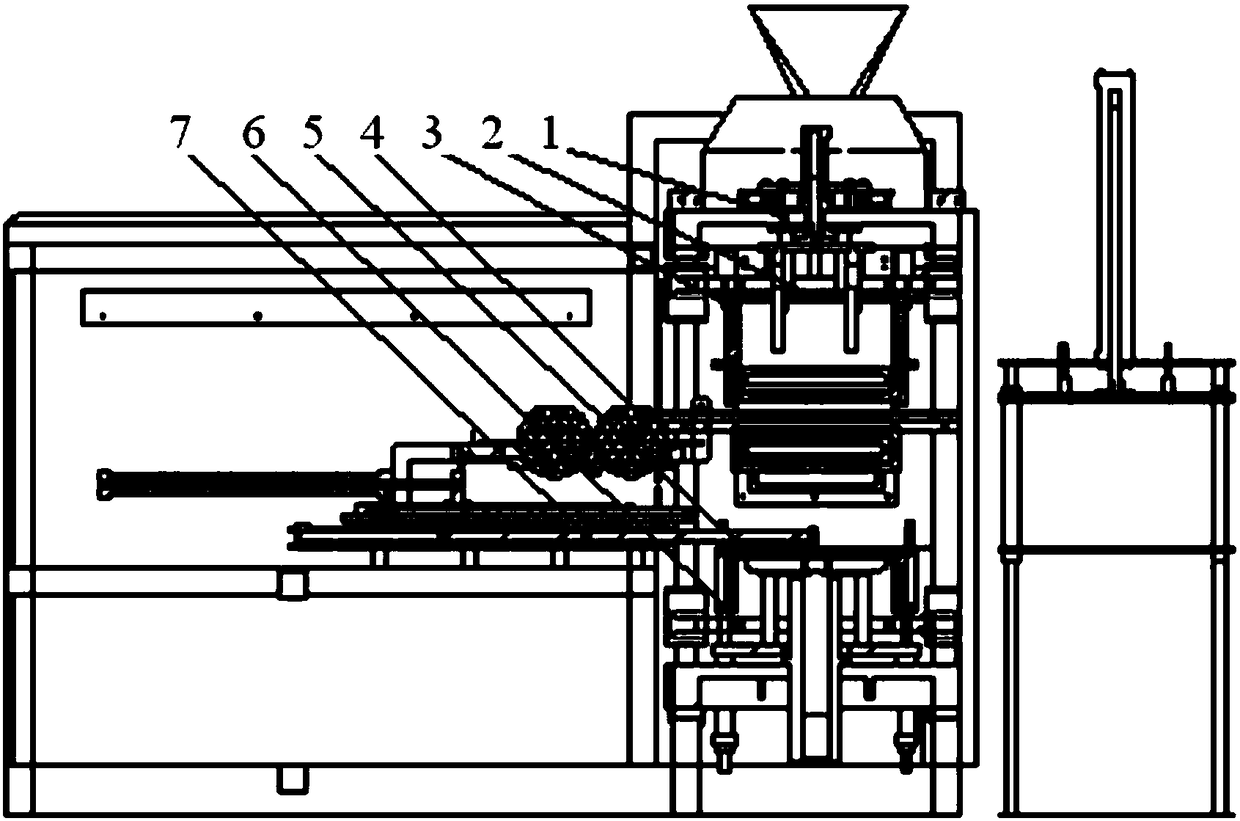

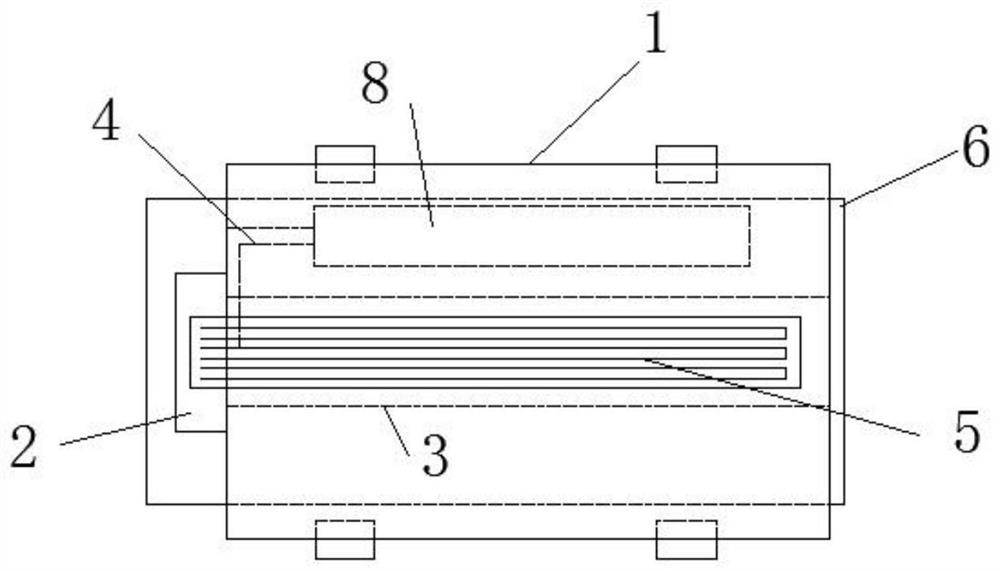

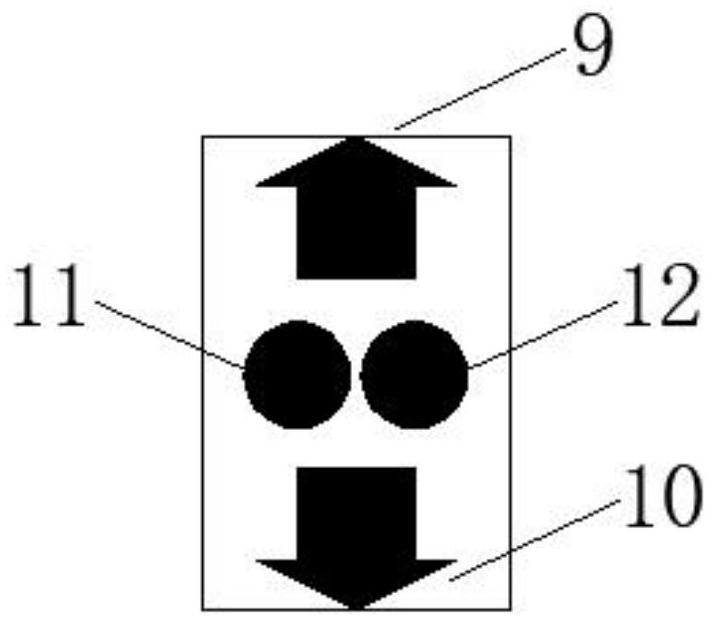

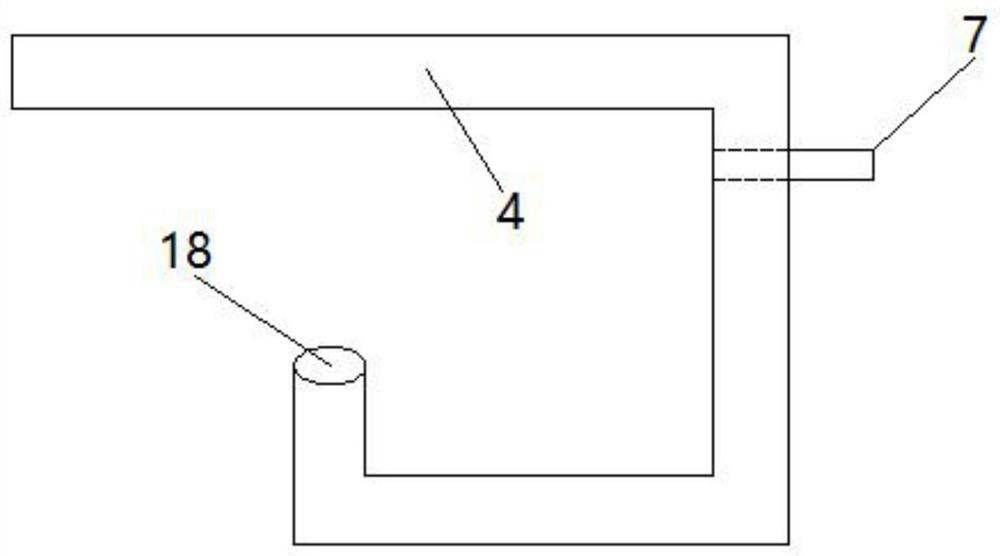

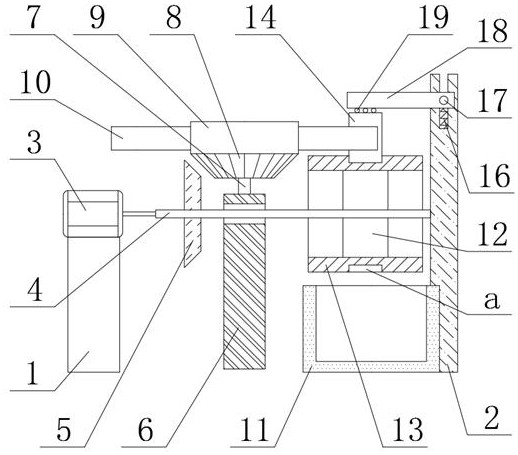

Sand discharging box of horizontal boxless moulding machine

ActiveCN106890952AConsistent compression ratioQuality Assurance and ImprovementMoulding machinesMoulding flasksEngineeringCompression ratio

The invention discloses a sand discharging box of a horizontal boxless moulding machine. The sand discharging box of the horizontal boxless moulding machine comprises a sand discharging box bottom plate (5), a sand discharging box frame (6) and a horizontal boxless moulding machine base frame (18), wherein a profiling dowel plate (15) is arranged below the sand discharging box frame (6); a plurality of mutually parallel profiling dowels (12) are vertically and fixedly installed on the upper surface of the profiling dowel plate (15); and the length of the profiling dowels (12) is determined by the outline of a mould, and the upper ends of all the profiling dowels (12) form the shape adaptive to the outline of the mould. By means of the technical scheme, due to the profiling structure of the ends of the dowels of the sand box, the sand mould compression ratio of all the parts inside the sand box is consistent, the compression force is relatively uniform, and therefore the quality of a sand mould formed in an extrusion mode is guaranteed and improved.

Owner:ANHUI XINNING EQUIP

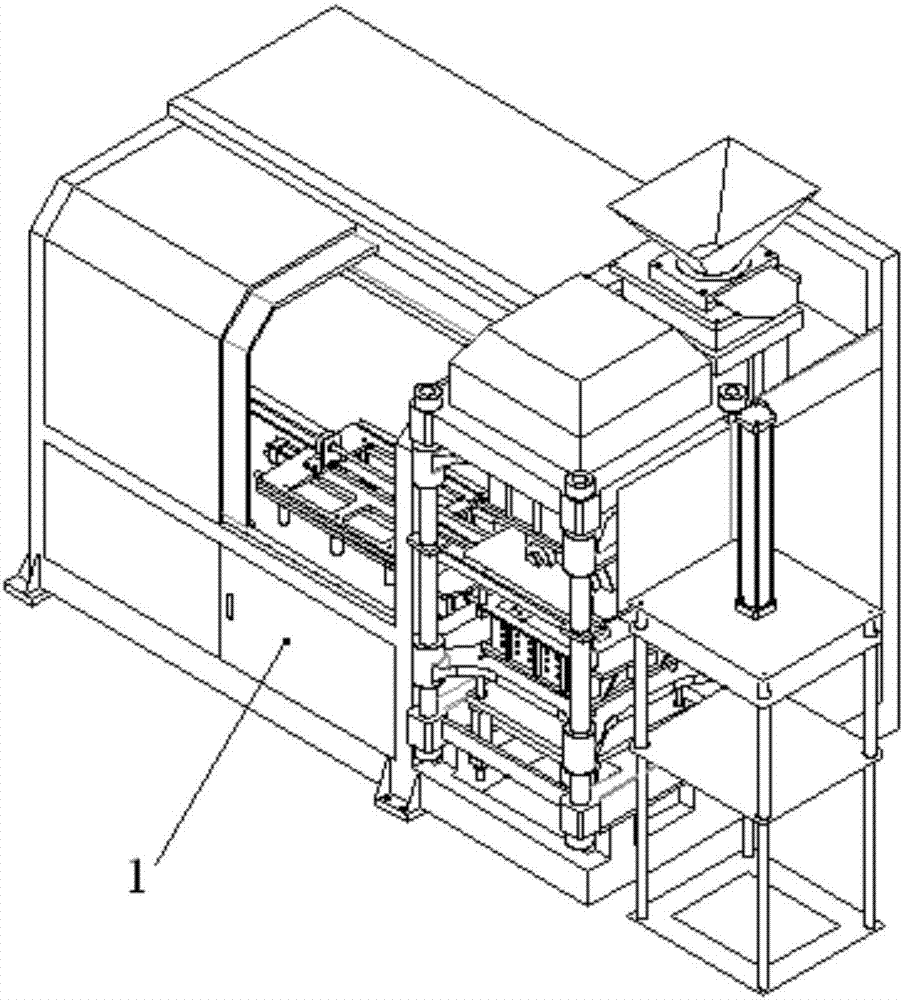

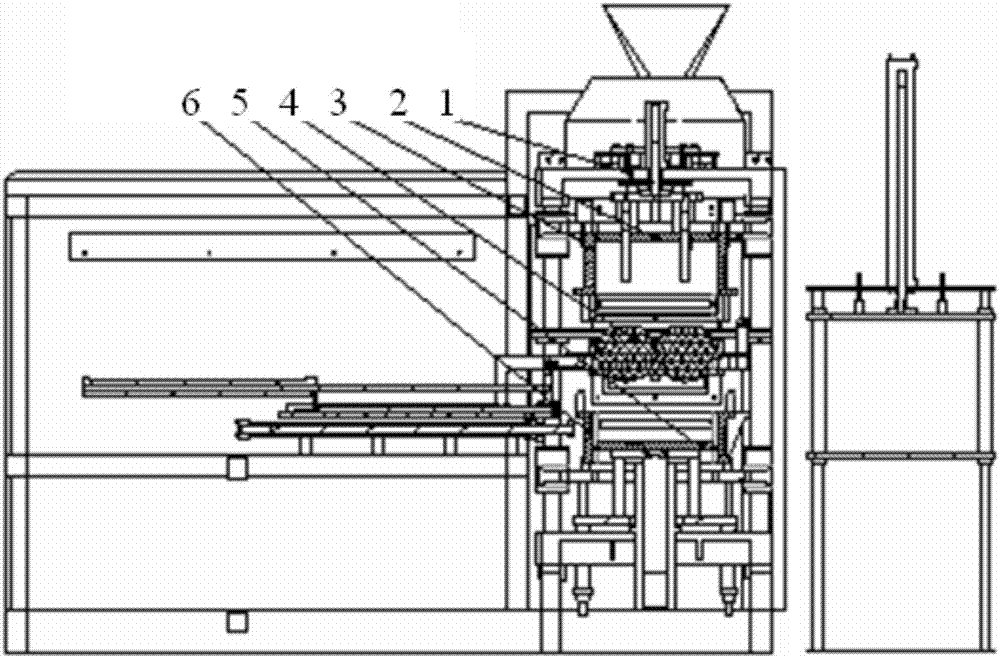

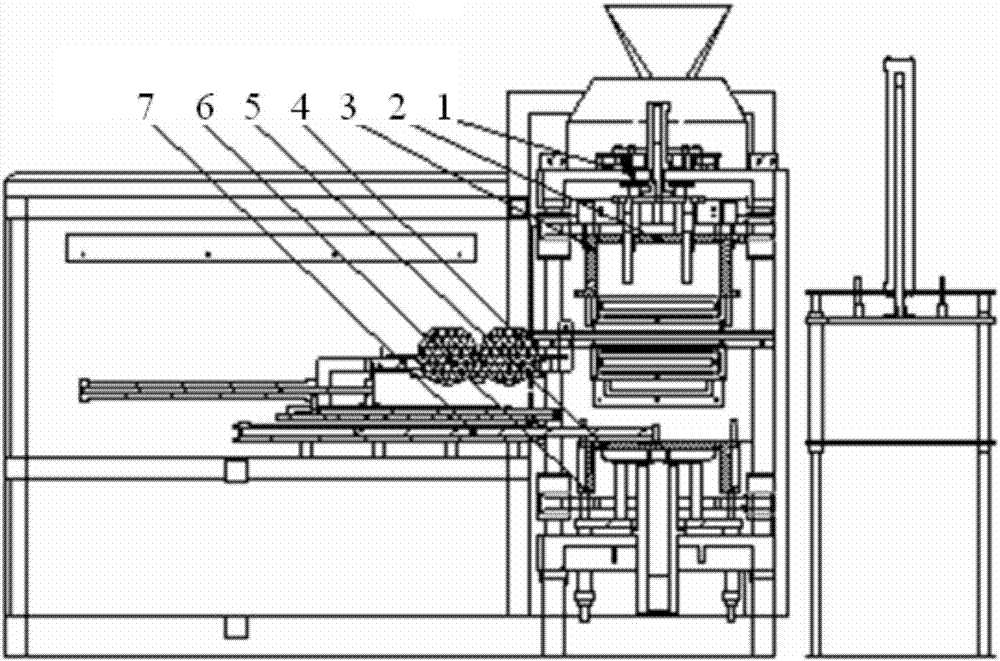

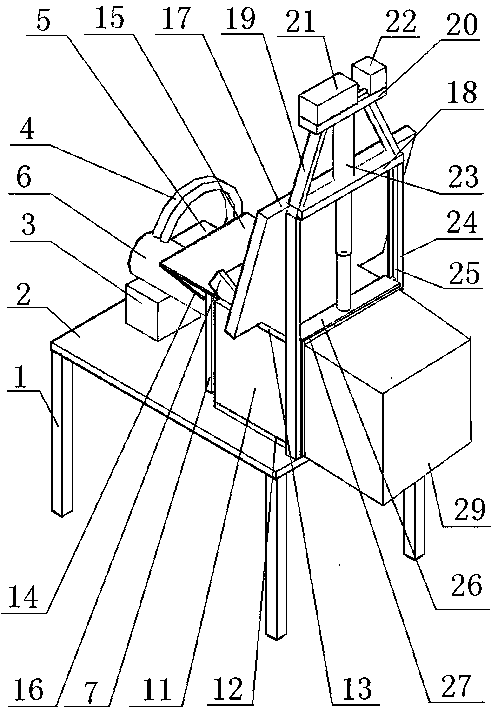

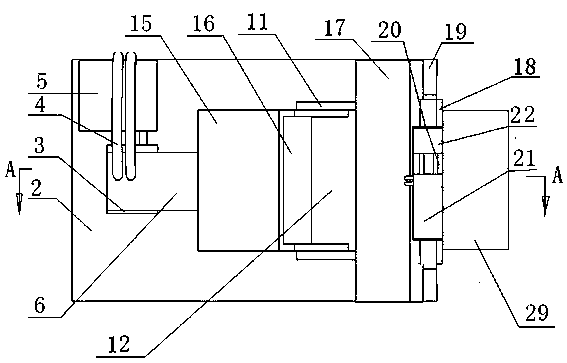

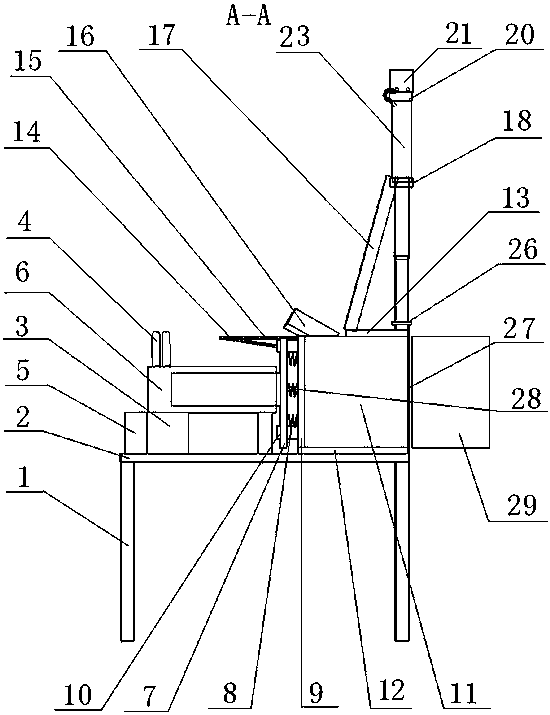

Activated carbon bar compression molding equipment

ActiveCN106965295AUniform compression forceImprove performanceCeramic extrusion diesAuxillary shaping apparatusActivated carbonStart button

The invention discloses activated carbon bar compression molding equipment which comprises a workbench, a support, a mold, a press-in mechanism, an ejector block, a clamping mechanism and a starting button. The workbench is provided with a table board. The support is mounted on the table board. The mold is used for compression molding of an activated carbon bar and can be vertically arranged on the table board. The mold is provided with two ends capable of relatively moving. The press-in mechanism is used for driving one end of the mold to move relative to the other end and is mounted on the support. The ejector block is used for supporting the other end of the mold and mounted on the table board. The clamping mechanism is used for clamping the mold and mounted on the support in a sliding manner to form sliding connection in the first direction. The starting button is used for controlling the press-in mechanism and mounted on the workbench. The first direction is perpendicular to the table board. The activated carbon bar compression molding equipment has the beneficial effects that even compression molding force can be applied to activated carbon powder, and therefore the performance is improved.

Owner:NANJING WOLIAN TECH

Large seal split molding mold

InactiveCN107755539ASimple structureFlexible useShaping toolsHollow articlesStructural engineeringSurface plate

Owner:宜兴市九洲封头锻造有限公司

A lower sand box of a horizontal boxless molding machine

ActiveCN106890952BConsistent compression ratioQuality Assurance and ImprovementMoulding machinesMoulding flasksMolding machineEngineering

The invention discloses a sand discharging box of a horizontal boxless moulding machine. The sand discharging box of the horizontal boxless moulding machine comprises a sand discharging box bottom plate (5), a sand discharging box frame (6) and a horizontal boxless moulding machine base frame (18), wherein a profiling dowel plate (15) is arranged below the sand discharging box frame (6); a plurality of mutually parallel profiling dowels (12) are vertically and fixedly installed on the upper surface of the profiling dowel plate (15); and the length of the profiling dowels (12) is determined by the outline of a mould, and the upper ends of all the profiling dowels (12) form the shape adaptive to the outline of the mould. By means of the technical scheme, due to the profiling structure of the ends of the dowels of the sand box, the sand mould compression ratio of all the parts inside the sand box is consistent, the compression force is relatively uniform, and therefore the quality of a sand mould formed in an extrusion mode is guaranteed and improved.

Owner:ANHUI XINNING EQUIP

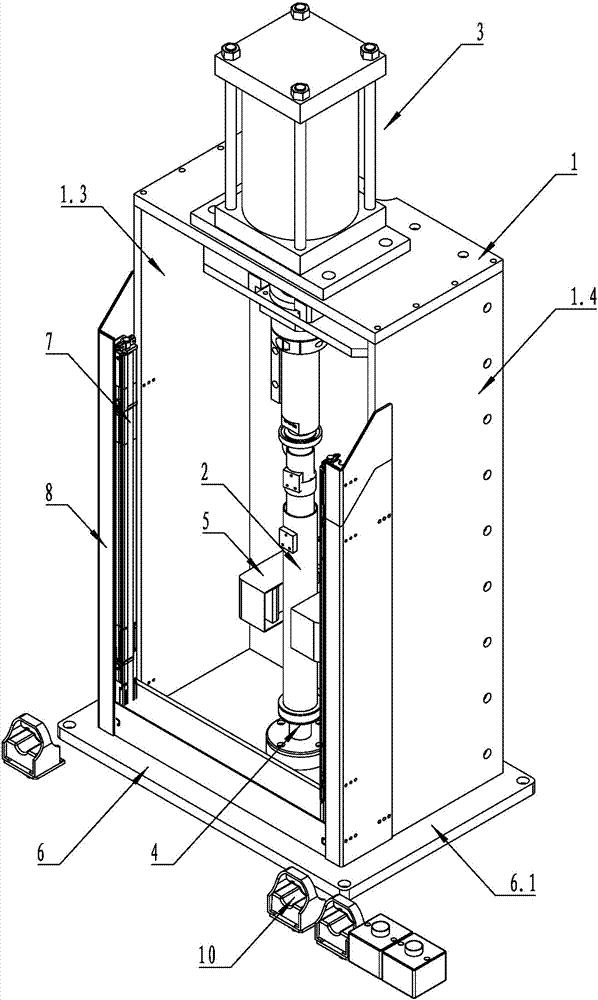

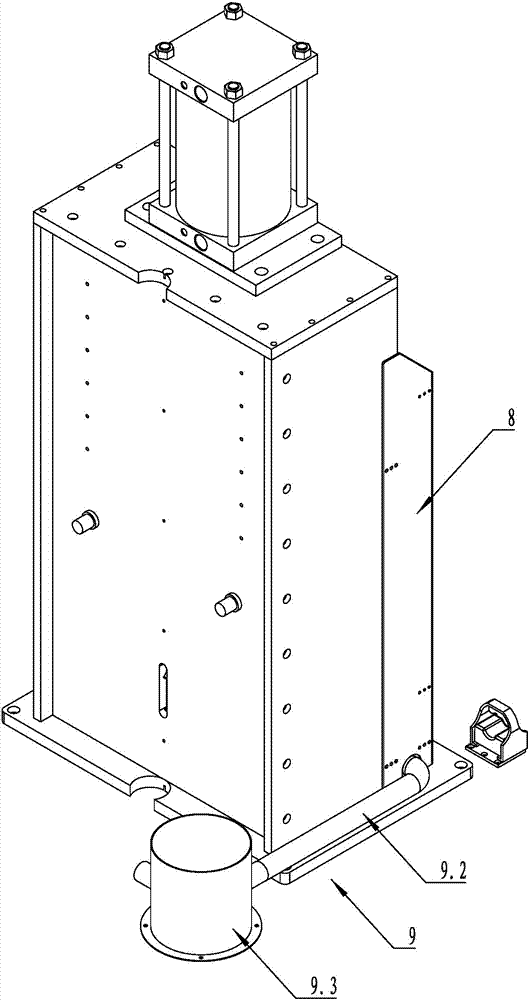

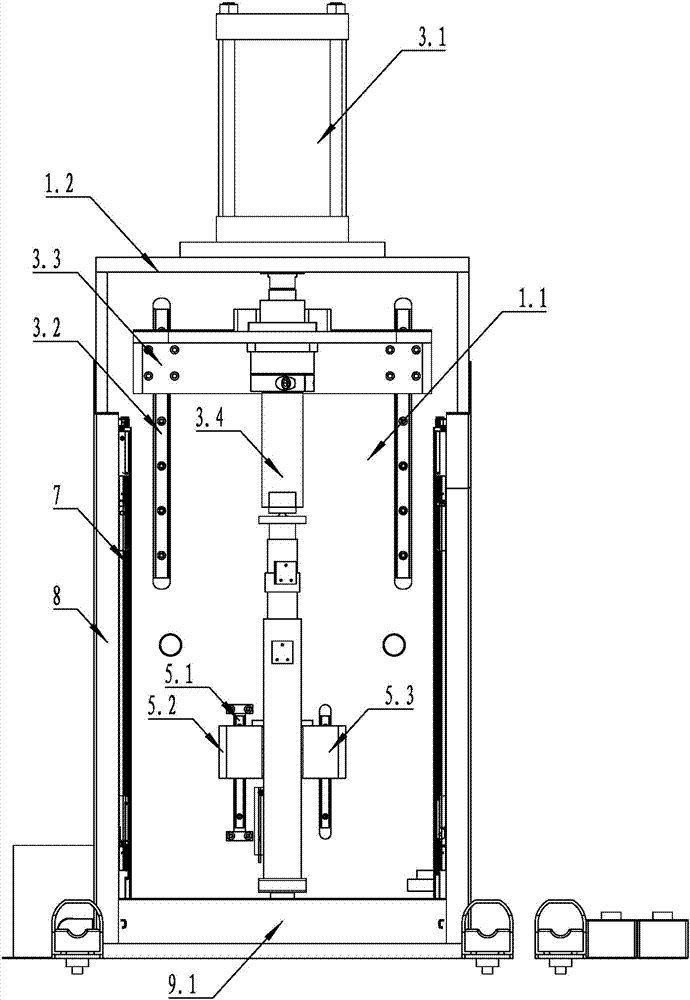

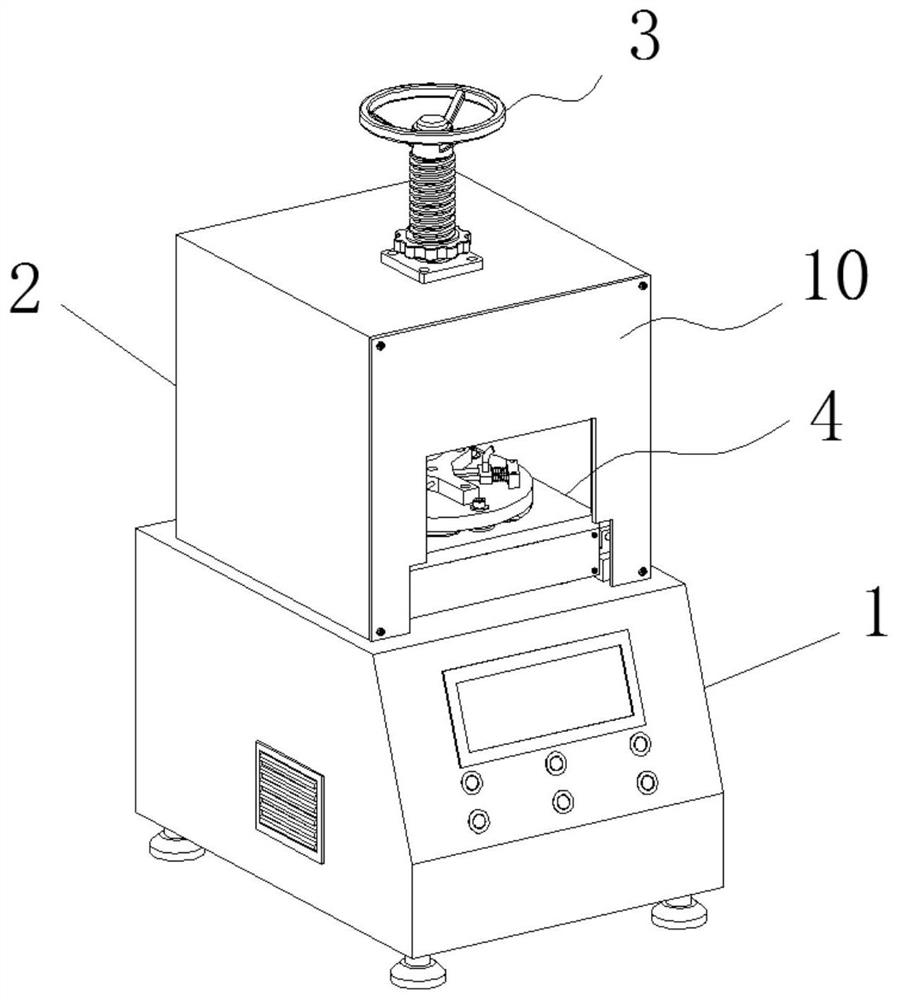

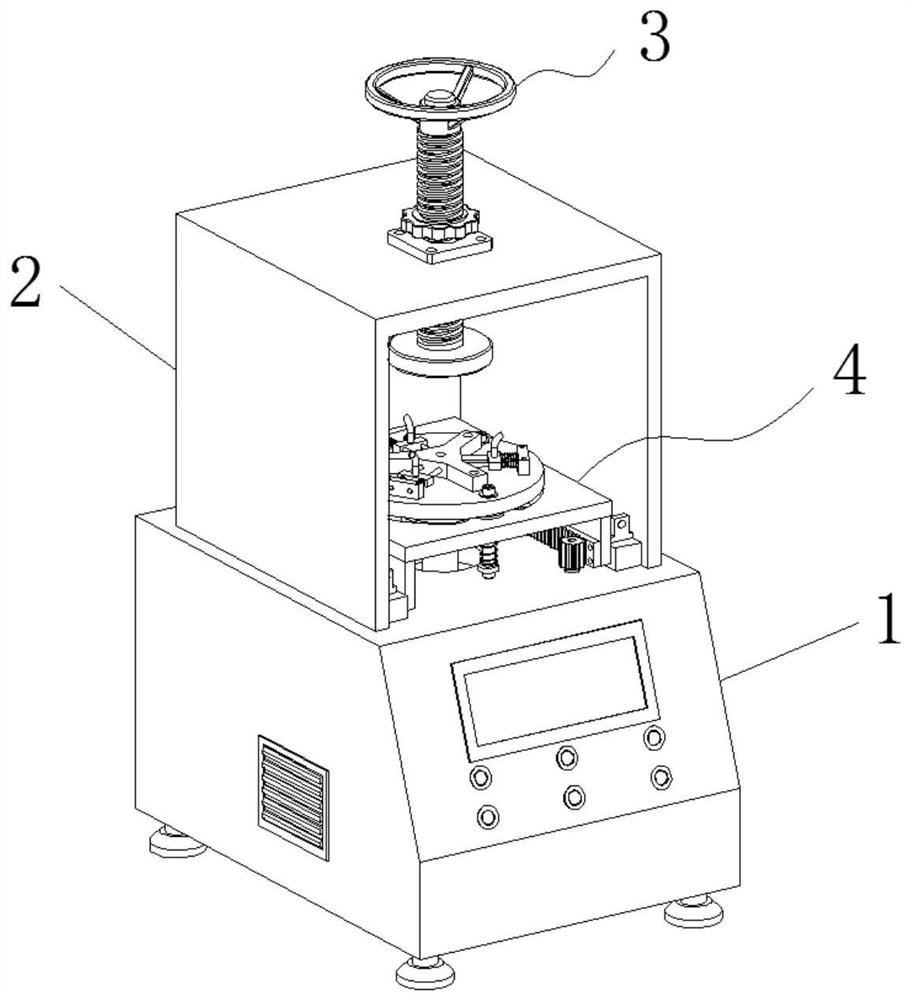

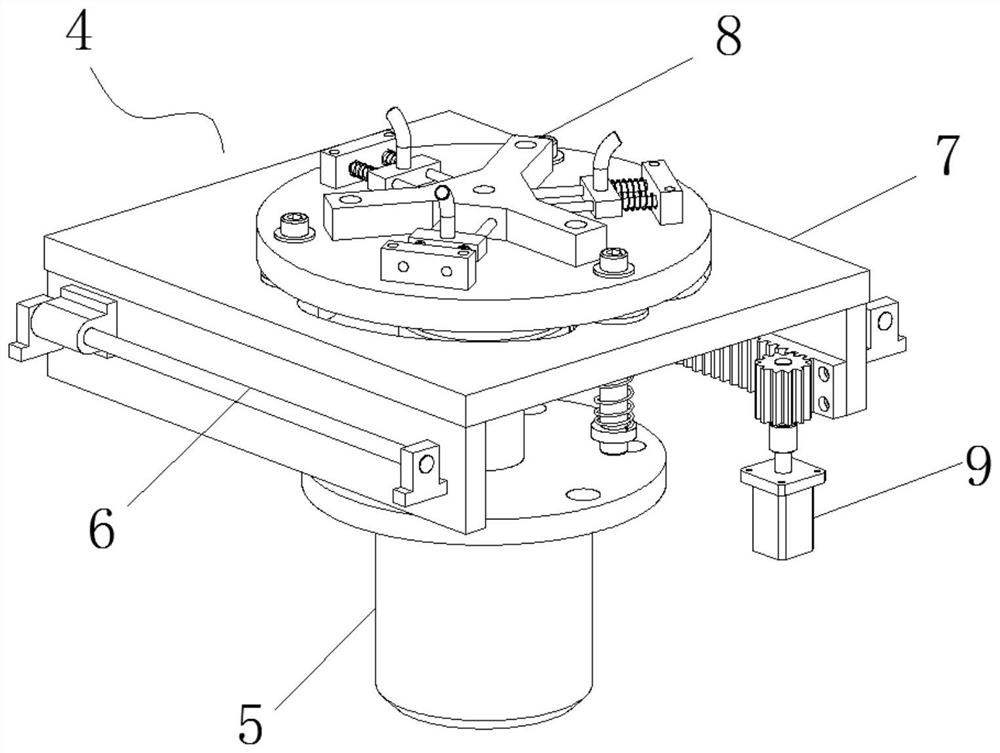

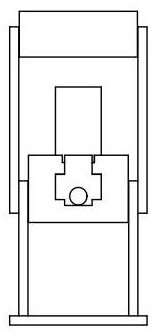

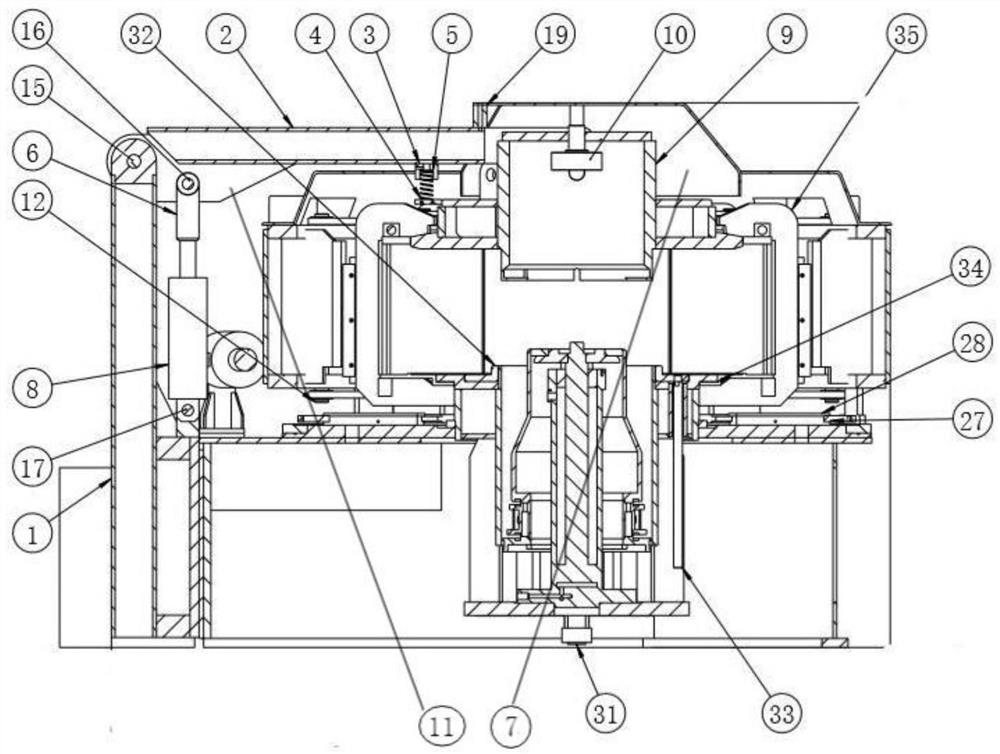

Hydraulic automatic tablet pressing machine

PendingCN112123845AAvoid accidental touchUniform compression forceShaping pressElectric machineryStructural engineering

The invention discloses a hydraulic automatic tablet pressing machine in the technical field of tablet pressing machines. The hydraulic automatic tablet pressing machine comprises a main machine seat,a frame body arranged on the main machine seat, a stroke adjusting mechanism arranged at the top of the frame body, a die driving mechanism assembly arranged in the main machine seat and the frame body, and a safety panel component arranged at the front side of the frame body, wherein the die driving mechanism assembly comprises a hydraulic cylinder installed in the main machine seat, double-guide-rail mechanisms installed on the inner walls of the two sides of the frame machine body, a horizontal movement installation seat mechanism arranged between the double-guide-rail mechanisms and horizontally installed on the double-guide-rail mechanisms in a sliding manner, a die bearing table mechanism arranged on the horizontal movement installation seat mechanism and installed on the horizontalmovement installation seat mechanism in a manner of floating up and down, and a motor driving mechanism arranged in the main machine seat and driving the horizontal movement installation seat mechanism to carry out horizontal movement. The invention provides a hydraulic automatic tablet pressing machine which much facilitates placing and taking for a die, and capable of effectively eliminating the potential safety hazards of operation.

Owner:南安市鄂丰机械有限公司

Traditional chinese medicine composition for sober-up and hepatic protection and a process for preparing the same

ActiveUS9968644B2Effectively soberRelieve drunkenness symptomsPowder deliveryDispersion deliverySteatosisAlcohol

The present invention relates to traditional Chinese medicine, particularly to a traditional Chinese medicine composition for sober-up and hepatic protection and a process for preparing the same. This composition is made from Radix Puerariae, Semen Hoveniae and Fructus Gardeniae. This composition has no significant effect on the body weight of mice. The hepatic TG level in animals of 1.400 g / kg·bw dosage group is significantly lower than that of the model control group, while the hepatic GSH level is significantly higher than that of the model control group. The degree of hepatic steatosis in animals of 1.400 g / kg·bw dosage group is significantly lower than that of the model control group. Therefore, the composition of the present invention has auxiliary protective effects on liver damages caused by alcohol. The process for preparing the composition comprises: extracting Radix Puerariae, Semen Hoveniae and Fructus Gardeniae with water, concentrating, drying, and pulverizing the extract.

Owner:INFINITUS (CHINA) CO LTD

Box cover fixing and popping device

PendingCN114348447ASimple structureUniform compression forceLidsStructural engineeringIndustrial engineering

The invention relates to a box cover processing device, in particular to a box cover fixing and popping device, and aims to provide the box cover fixing and popping device which is simple in structure and uniform in compression stress, the box cover fixing and popping device comprises a base, the base is L-shaped, a rotating shaft hinge seat is arranged at the upper end of the base, and a concave clamping position is arranged in the base; the rotary cover plate is hinged to the upper part of the base, and the length of the rotary cover plate is equivalent to that of the base; the rotating door is arranged at an opening formed by the rotating cover plate and the base, the rotating door comprises a cover plate, a hinged plate and a connecting plate, the hinged plate and the cover plate are arranged at the two ends of the connecting plate in an anti-parallel extending mode, and the coincident end of the connecting plate and the hinged plate is hinged to the base; the connecting rod is arranged on the rotary cover plate and the rotary door, one end of the connecting rod is hinged to the rotary cover plate, and the other end is hinged to the hinge plate; the pop-up mechanism comprises a pop-up spring arranged on the inner wall and a pop-up button arranged on the inner side of the rotating door, and the box cover fixing and pop-up device is simple in structure, even in force application, easy and reliable to operate, capable of easily achieving pressing and pop-up actions of the box cover and very practical.

Owner:青岛全诊生物技术有限公司

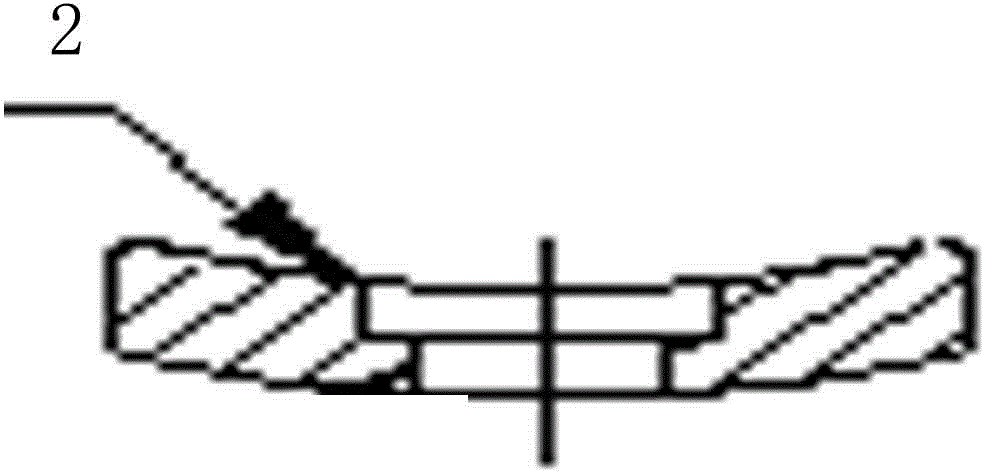

Cable shielding layer processing structure of plug

ActiveCN102983459BPrevent looseningNot easy to damageCoupling protective earth/shielding arrangementsShielded cableStructural engineering

The invention discloses a cable shielding layer processing structure of a plug. The cable shielding layer processing structure of the plug comprises a shielding sleeve (1), a shielding cable clamp (2), and a fastener. A shielding layer installing hole (4) is formed in one side of the shielding sleeve (1). A cable shielding layer is arranged inside the shielding layer installing hole (4). The fastener (3) is installed on the shielding layer installing hole (4). The shielding cable clamp (2) is arranged inside the shielding layer installing hole (4). The fastener (3) corresponds to the shielding cable clamp (2) and fastens the cable shielding layer tightly through the shielding cable clamp (2). The cable shielding layer processing structure of the plug has the advantages of being wide in compatible cable outer diameter range, small in the number of spare parts, simple to operate, and reliable in the connection of the shielding layer.

Owner:TAIZHOU HANGYU ELECTRICAL DEVICE

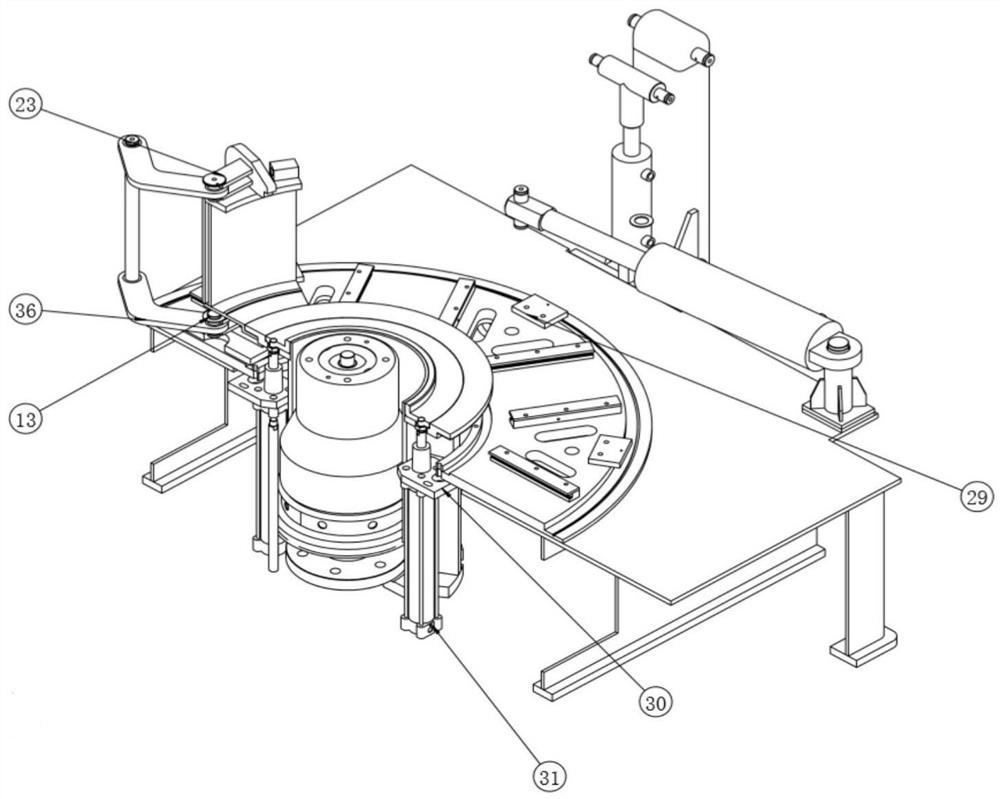

Novel hydraulic rocker arm knurling type high-temperature vulcanizing device for retreaded tire

The invention discloses a novel hydraulic rocker arm knurling type high-temperature vulcanizing device for a retreaded tire. The vulcanizing device comprises an upper cover opening and closing mechanism, a tire jacking mechanism, a clamping mechanism and a heating mechanism. The vulcanizing device has the beneficial effects that eight arched bases are arranged in a petal shape, and each arched base is internally provided with a heating plate; each arched base is pushed through a connecting rod, and therefore the arched bases can be closed and opened like petals; thus, a tire mold can be evenly clamped, and heated; a box body is pushed by a mold locking oil cylinder to rotate, and the box body and the connecting rod are rotated synchronously; the stability and uniformity of operation are ensured, and the uniform pressing force of the eight arched bases in a petal shape can be ensured; two pressing blocks are arranged on each arched base; when the box body is rotated in place, and the two sides of each arched base are pressed through the pressing blocks of the box body; after pressing, force does not need to be applied through a hydraulic cylinder, and therefore energy consumption is reduced; the operation time of a hydraulic device is shortened, and the fault rate is reduced; and the reliability is improved.

Owner:青岛途隆轮胎有限公司 +1

A crankshaft drilling and clamping device

ActiveCN109202497BUniform compression forceWork clamping meansPositioning apparatusCrankClassical mechanics

Owner:宁波健实机械有限公司

A flexible ring-pack capacitive sensor installation tool and installation method

ActiveCN113319785BGuaranteed detection accuracyEasy to operateMetal-working hand toolsStructural engineeringElectric cables

The invention discloses a flexible ring-pack capacitive sensor installation tool and an installation method, which belong to the technical field of cable joint detection equipment installation. It includes two fixed rings arranged on both sides of the cable joint, and a press-fitting mechanism rotatably connected with the fixed rings; the press-fitting mechanism includes a ring sleeve, a driving part and a press-fitting wheel, and the ring sleeve is sleeved on the fixed ring. On the outside, the driving member is provided on the ring sleeve, and the driving member is provided with the pressing wheel for wrapping the flexible ring-pack capacitive sensor on the cable joint. The invention adopts the installation tool and the installation method to operate in a standardized manner, which ensures that the flexible capacitive sensor is not affected by dirt and uneven force, and also ensures that the shape and shielding effect of the metal shielding net are not affected after installation, thereby ensuring that the capacitive sensor is not affected. In addition, the present invention can complete the installation of the flexible capacitive sensor and the metal shielding net in sequence, with convenient operation and high efficiency.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

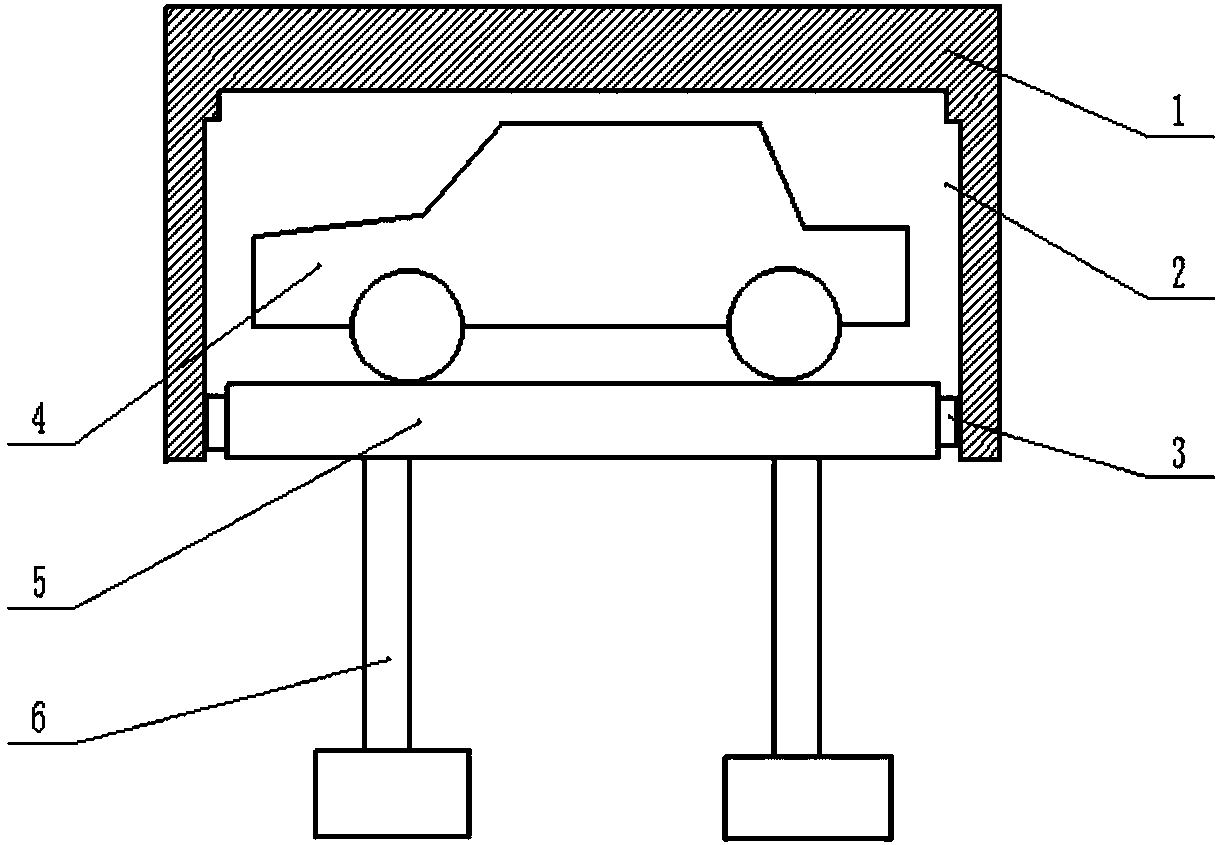

Flattening machine for scraped car

The invention discloses a flattening machine for a scraped car. The flattening machine comprises a compression body box and a lifting mechanism; the compression body box is of a square body structurewith an opening in the lower bottom surface, and the size of the compression body box is slightly larger than that of the scraped car; the lifting mechanism comprises a compression plate and lifting devices, wherein the compression plate is matched with the opening of the lower bottom surface of the compression body box, the to-be-compressed scrapped car is placed on the compression plate, and thelifting mechanism is used for realizing lifting of the compression plate through multiple hydraulic devices; and protrusions are arranged on four outer side surfaces of the compression plate, inwardsrecessed grooves are formed in four inner side surfaces of the compression body box, and the projections are just matched with the grooves. According to the flattening machine for the scraped car, the grooves and the protrusions are arranged, so that better coordination of the compression plate is realized when the scraped car is compressed upwards, the compression stress is more uniform, the certain limiting effect is further realized, and the lifting column is assisted.

Owner:湖北天银报废汽车回收拆解有限公司

Welding fixture for laser circumferential seam welding of multi-layer thin-wall ring part

ActiveCN107803605AImprove thermal conductivityImprove cooling effectWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCopper

The invention discloses a welding fixture for laser circumferential seam welding of a multi-layer thin-wall ring part. The welding fixture comprises a ring-shaped positioning plate made of red copper,and the surface of the positioning plate is plated with chromium; the positioning plate is provided with a gland in a matched mode, the gland is made of red copper, and the surface of the gland is plated with chromium; a taper gasket is arranged on one side of the positioning plate and sleeved with a fastening device for pressing the gland and the positioning plate; and a positioning device is further arranged between the positioning plate and the gland. In the laser circumferential seam welding process, parts are effectively prevented from adhering to the fixture, the phenomenon of welding deformation is eliminated, and the problem of buckling deformation of the parts during welding is solved.

Owner:AECC AVIATION POWER CO LTD

A strain gauge sticking device

ActiveCN111981009BUniform compression forceImprove paste qualityLiquid surface applicatorsMaterial gluingAdhesiveStrain gauge

The invention provides a strain gauge sticking device, which includes an installation housing, a conveying device, an adhesive spraying device and a lifting pressure plate device; the upgraded pressure plate device includes a lifting unit and a pressure plate, and the device of the present application transports the strain gauge through the conveying device, and the adhesive The spraying device sprays the adhesive on the sticking surface of the strain gauge, and at the same time cooperates with the lifting unit to drive the lifting movement of the pressure plate to press and paste the strain gauge on the panel of the test piece; in addition, there are walking rollers at the four corners of the bottom of the installation shell, which can make the strain gauge sticking equipment Sliding freely on the panel of the test piece, and cooperating with the conveying device to continuously transport the strain gauge and the adhesive spraying device to spray the adhesive on the strain gauge, the strain gauge can be pressed and pasted on each position of the test piece panel sequentially in an assembly line, and pressed The tightness is uniform and the paste quality is high.

Owner:HUNAN LIANZHI BRIDGE & TUNNEL TECH

Pressing device for lighter manufacturing

InactiveCN111703608AUniform compression forceAvoid misalignmentPackagingElectric machineEconomic benefits

The invention relates to the technical field of lighter pressing, in particular to a pressing device for lighter manufacturing. The pressing device comprises a fixing block and a vertical plate, wherein the top end of the fixing block is fixedly connected with a motor, the tail end of a main shaft of the motor is fixedly connected with a rotating column, the right end of the rotating column is rotationally connected with the left end of the vertical plate, the outer side of the rotating column is fixedly connected with a first bevel gear, a positioning rod is arranged on the outer side of therotating column, and the top end of the positioning rod is rotationally connected with a connecting column. According to the pressing device, the first bevel gear, a second bevel gear and a rotating disc are arranged, so that the pressing force of a bent plate on a packaging sticker is uniform, the steps of lighter conveying and sticker pressing are synchronous, bubbles are prevented from appearing on the sticker, the phenomenon of dislocation of the sticker is prevented, the attractiveness of the lighter is improved, which is beneficial to the selling of the lighter is; and the design conceptis novel, the design is scientific, the pressing device has huge economic benefits and wide market prospects, and is worthy of popularization and use.

Owner:马玉荣

Pushing mechanism

InactiveCN109552864ASqueeze evenlyUniform compression forceConveyorsFood shapingWall plateEngineering

The invention discloses a pushing mechanism. The pushing mechanism comprises a panel, a buffer plate, a pushing plate, positioning pins, a wall plate, a bottom plate, a top plate, a sealing plate, a feeding inlet, a tool rest and a forming die. The pushing mechanism is characterized in that a telescopic pump A is arranged on the panel, the telescopic pump A is connected with the buffer plate, thebuffer plate is provided with a buffer spring and a trigger switch, the buffer spring is connected with the pushing plate, the bottom plate is arranged below the pushing plate, the bottom plate is provided with the wall plate, the top plate (13) and the feeding inlet are formed in the wall plate, the sealing plate is arranged at the bottom of the feeding inlet, the sealing plate is connected witha connecting plate, the connecting plate is connected with a positioning pin, the positioning pin is fixed to the pushing plate, the top plate is connected with a supporting plate, the supporting plate is connected with a supporting frame, the supporting frame is connected with a cross beam A, a longitudinal beam is arranged below the cross beam A, a sliding groove is formed in the longitudinal beam, the tool rest is arranged in the sliding groove, a telescopic pump B is connected to the upper part of the tool rest, a blade is arranged below the tool rest, and the forming die is arranged on the right side of the blade. The pushing mechanism is uniform in compression stress, simple in structure, convenient to operate, short in machining time, quick and practical.

Owner:唐能慧

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com