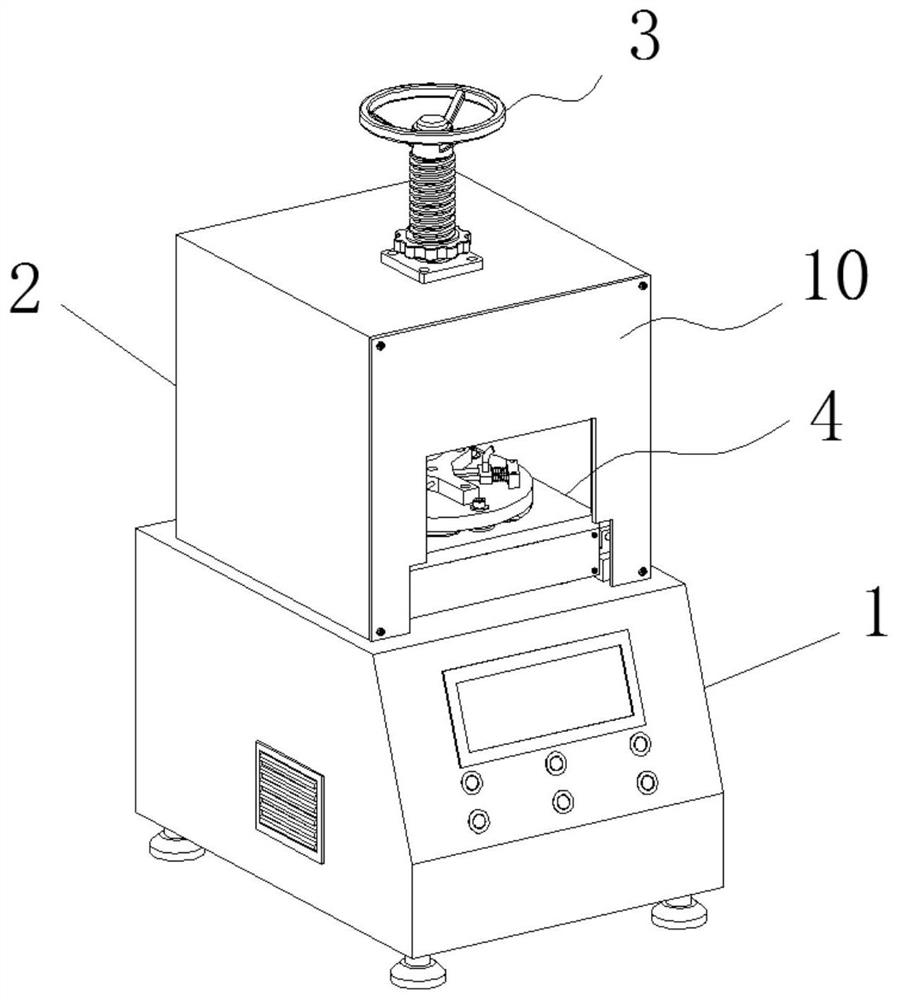

Hydraulic automatic tablet pressing machine

An automatic tablet press and hydraulic technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve problems such as safety hazards, cumbersome operations, and the inability to never touch the start button by mistake, so as to ensure uniform pressing Effects of force bearing, elimination of operational safety hazards, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

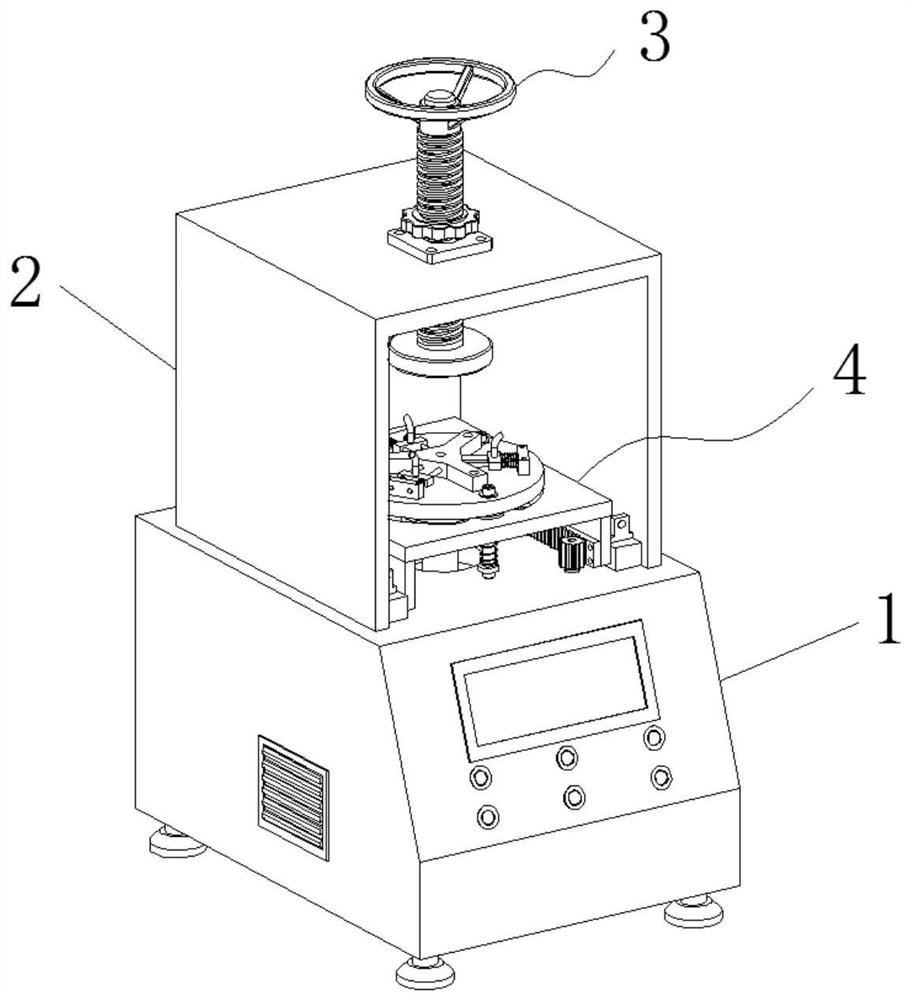

[0040] Such as Figure 4As shown, the stroke adjustment mechanism 3 includes a nut seat 301 embedded and installed on the top of the frame body 2. The upper end of the nut seat 301 has a square flange structure, and the four corners of the square flange structure are fixed to the top of the frame body 2 by countersunk head screws. The inner cavity of the nut seat 301 is screwed with an adjusting stud 302, the lower end of the adjusting stud 302 is fixedly provided with a limit plate 303, and the upper end of the adjusting stud 302 is equipped with an adjusting knob 304, which is convenient for applying force to rotate the adjusting stud 302 to adjust The height of the limit pressing plate 303, the outer wall of the adjusting stud 302 and the top of the frame body 2 are screwed with a locknut 305, and the locknut 305 can be locked downwards to prevent adjustment when abutting against the top of the frame body 2 The effect of stud 302 loosening.

Embodiment 2

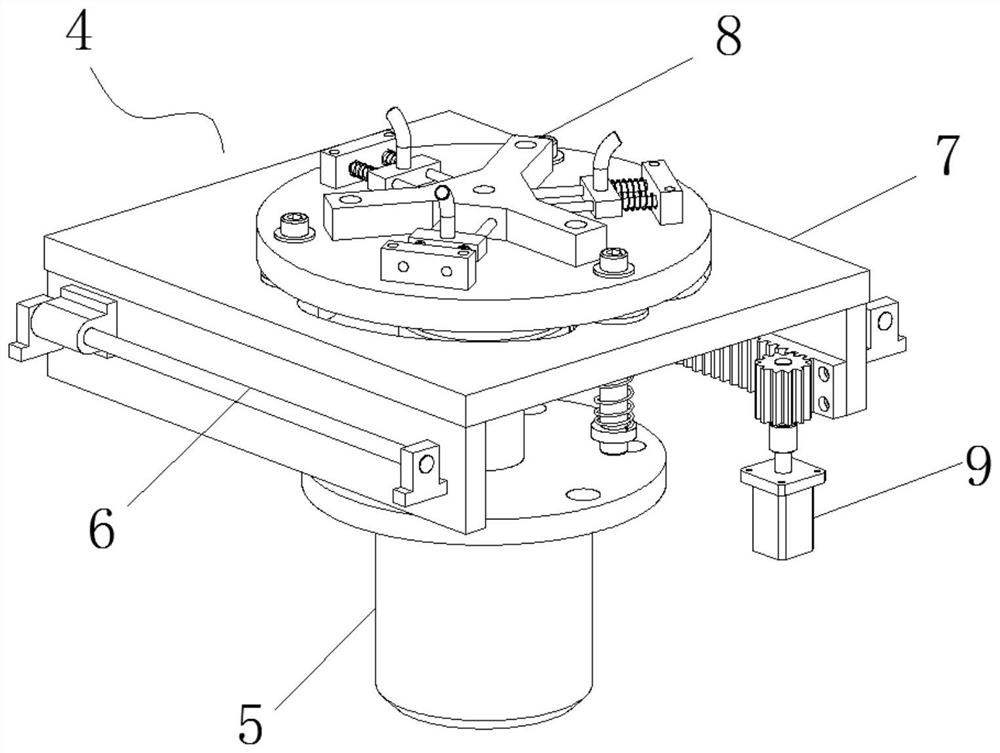

[0042] Such as Figure 5 As shown, the double guide rail mechanism 6 includes two translation sliders 601 arranged at intervals on the left and right sides. The two translation sliders 601 are parallel to each other. 2. On the inner walls of both sides, linear bearing seats 603 are slidably installed on the two translation sliding rods 601 respectively. It can slide axially along the translation slide bar 601 when force is applied.

Embodiment 3

[0044] Such as Figure 6 As shown, the translation mounting seat mechanism 7 includes a horizontal mounting plate 701, the left and right sides of the bottom of the horizontal mounting plate 701 are respectively fixed with mounting side plates 702 for installing the linear bearing seat 603, and the bottom front side of the horizontal mounting plate 701 is installed with The sealing panel 703 plays an aesthetic role ( figure 2 Hidden block panel 703), the middle part of the horizontal mounting plate 701 is provided with a relief opening 704, to facilitate the passage of the top telescopic end of the hydraulic cylinder 5, the circumference of the relief opening 704 is evenly embedded with three bushings 705, and the bushing 705 The inner cavities are all slidably equipped with a lifting slide bar 706, and the upper end of the lifting slide bar 706 is fixedly installed with the mold bearing platform mechanism 8. A limit stop is set and fixed by an axial screw.

[0045] When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com