Activated carbon bar compression molding equipment

A molding equipment and activated carbon technology, applied in auxiliary molding equipment, ceramic molding machines, ceramic extrusion dies, etc., can solve the problems of destroying the pores of activated carbon wool, reducing the water purification performance of activated carbon rods, and unreasonable structure and compression molding process. Achieve uniform compression force and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

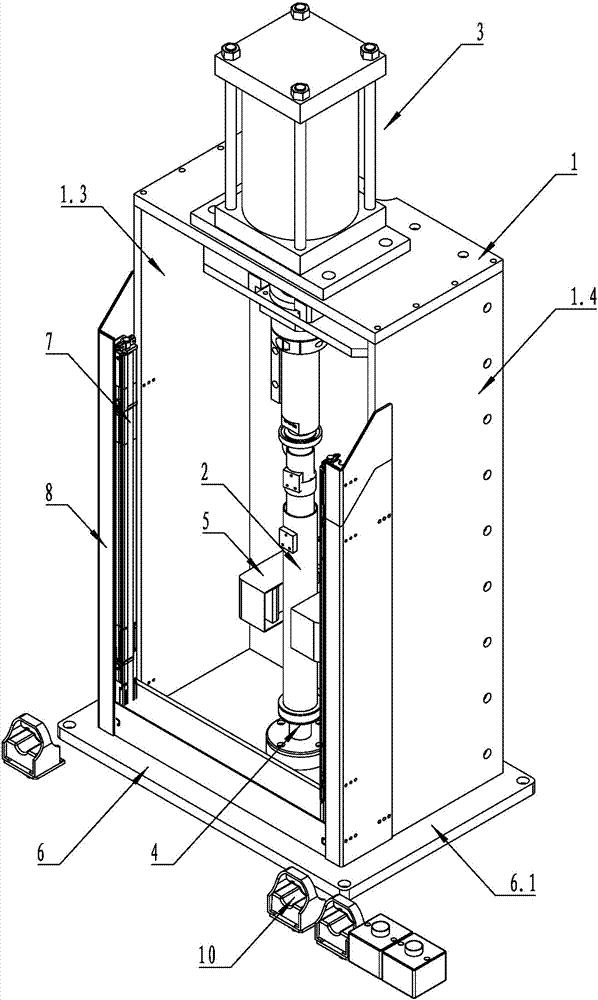

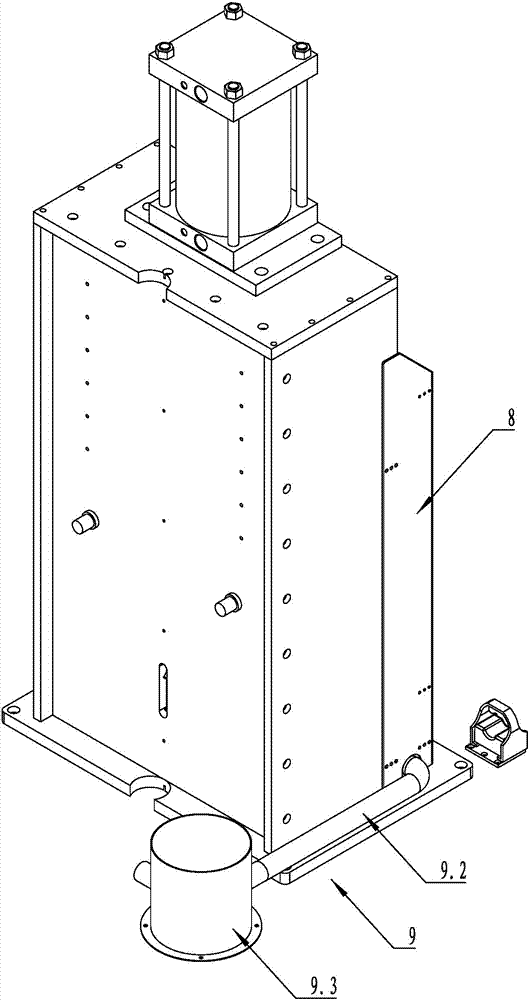

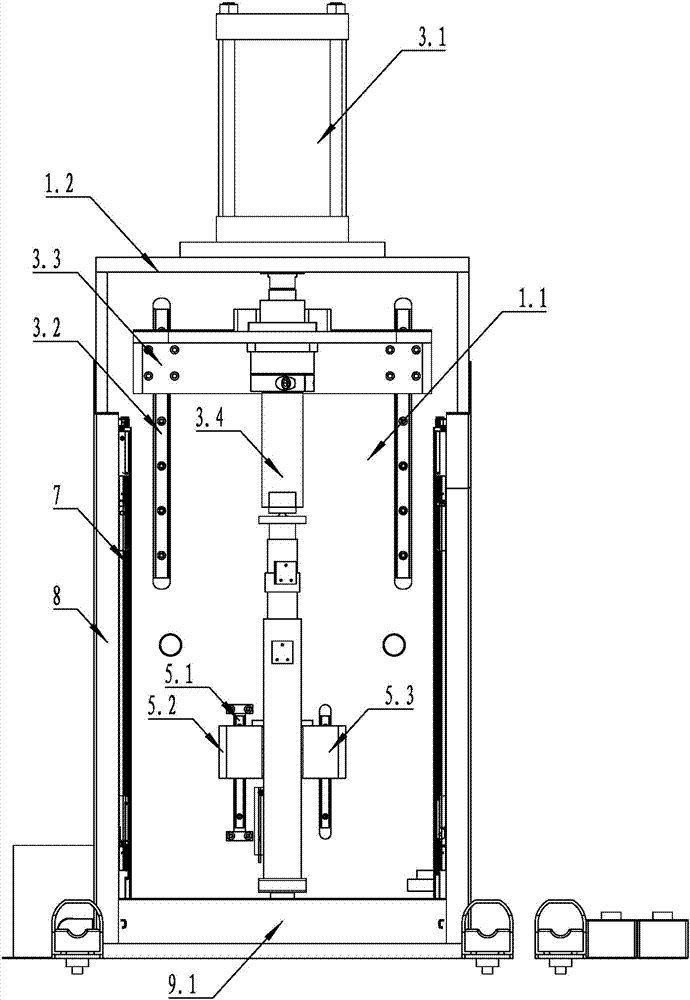

[0024] Such as Figures 1 to 5 As shown, a kind of activated carbon rod compression molding equipment comprises: workbench 6, and workbench 6 has table top 6.1; Support 1, it is installed on the table top 6.1; The mold 2 that is used for compression-molded activated carbon rod molding, it can vertically set Above the table 6.1, the mold 2 has two relatively movable ends; a press-in mechanism 3 for driving one end of the mold 2 to move relative to the other end, which is installed on the bracket 1; used to support the mold The top block 4 at the other end of 2 is installed on the table 6.1; the clamping mechanism 5 for clamping the mold 2 is slidably installed on the bracket 1 to form a sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com