Pushing mechanism

A push mechanism and push plate technology, applied in the field of machinery, can solve the problems of affecting the quality of finished products, unsatisfactory products, uneven force, etc., and achieve the effect of convenient operation, short processing time and uniform compression force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

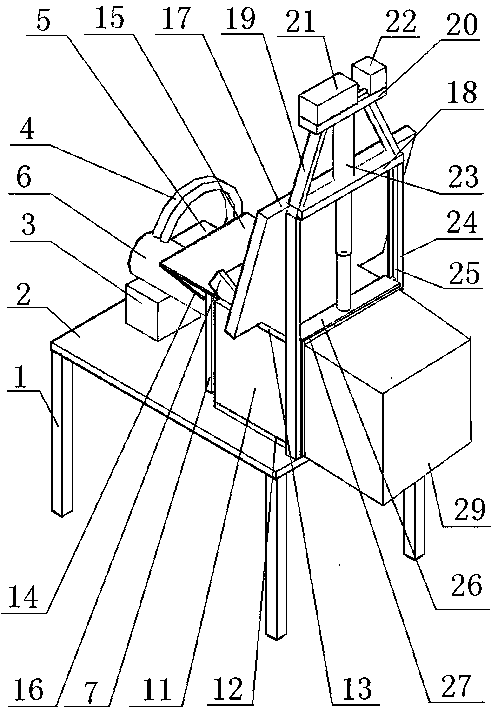

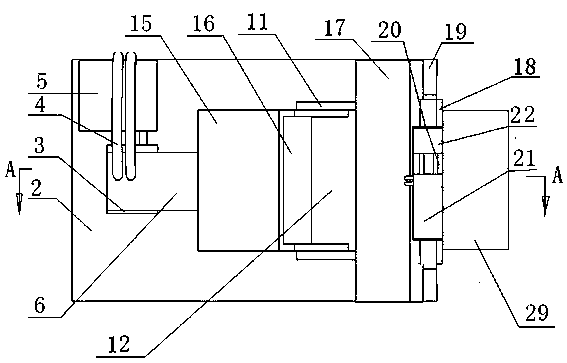

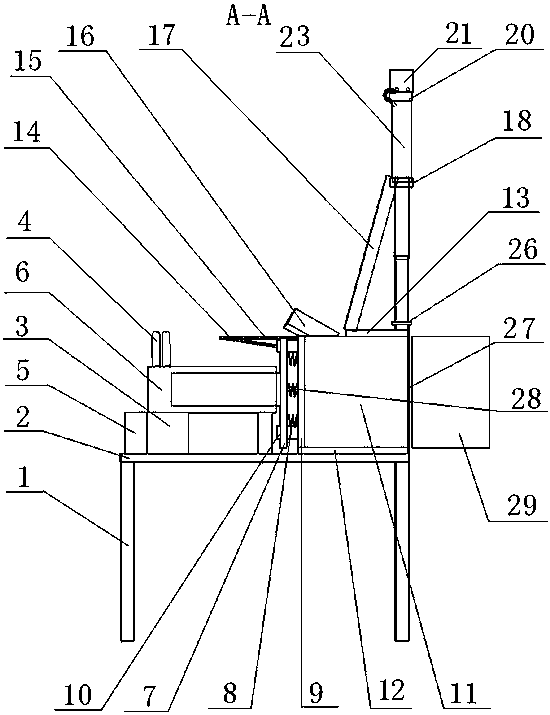

[0024] The specific implementation, structure, features and functions of the push mechanism proposed according to the invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0025] see figure 1 and Figure 8 , a pushing mechanism, comprising a panel 2, a buffer plate 7, a pusher plate 9, a positioning pin 10, a wall plate 11, a bottom plate 12, a top plate 13, a sealing plate 15, a feed port 16, a knife rest 26, and a molding die 29, It is characterized in that: there is a telescopic pump A6 on the panel 2, and the telescopic pump A6 is connected to the buffer plate 7, the buffer spring 8 and the trigger switch 28 are arranged on the buffer plate 7, the buffer spring 8 is connected to the pusher plate 9, and there is a bottom plate under the pusher plate 9 12. There is a wallboard 11 on the bottom plate 12, a top plate 13 and a feed port 16 on the top of the wall board 11, and a sealing plate 15 at the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com