Light and efficient polarizing film bending manufacturing tool

A polarizing film and high-efficiency technology, applied in the field of film processing molds, can solve the problems of uneven force, easy damage to the polarizing film, good lamination effect, etc., to achieve good flatness and smoothness, uniform pressing force, and processing. Create easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

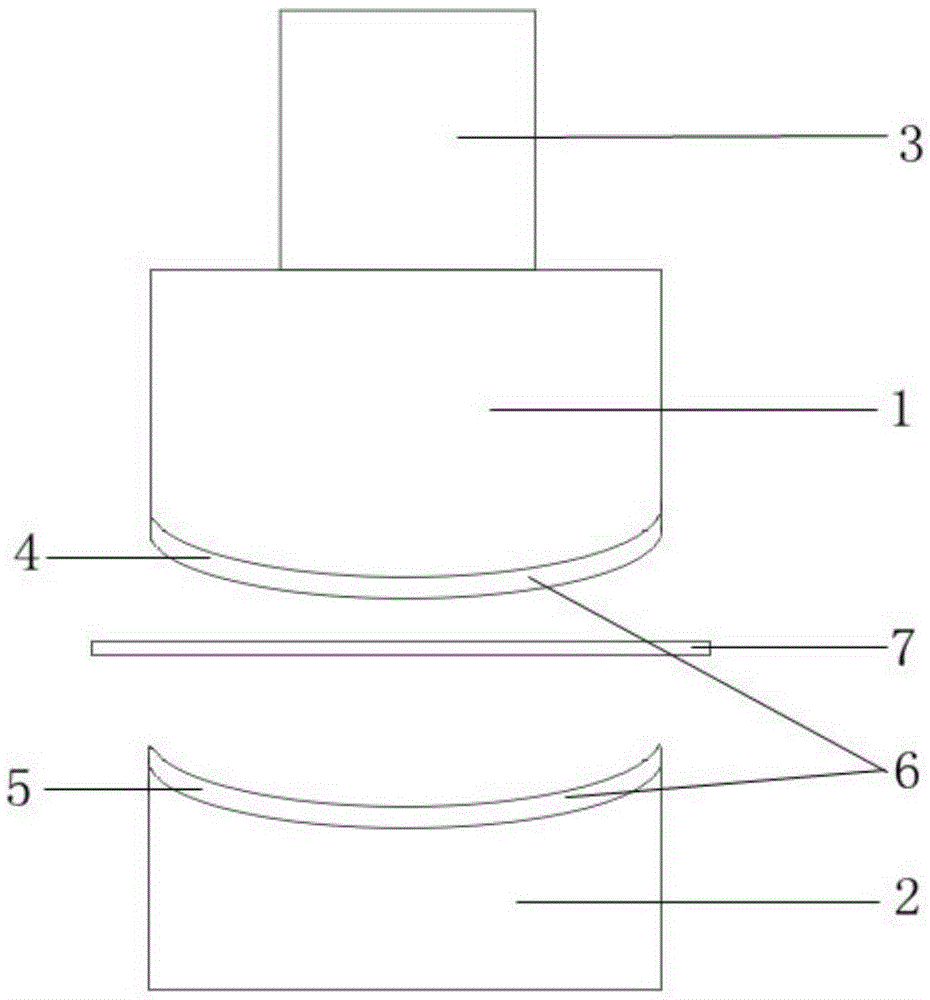

[0021] combined with figure 1 , a lightweight and efficient polarizing film bending production mold, including extrusion device 1, fixed molding device 2, cylinder 3, the extrusion device 1 is provided with an arc-shaped convex extrusion device working surface 4, the fixed The molding device 2 is provided with a groove that matches the working surface 4 of the extrusion device; the working surface 4 of the extrusion device and the working surface 5 of the fixed molding device are provided with a ceramic layer 6; the extrusion device 1 and The cylinder 3 is fixedly connected, and the cylinder 3 provides power for the extruding device 1 and presses against the fixed forming device 1 to bend the polarizing film 7 into shape.

[0022] The extrusion device 1 and the fixed molding device 2 are made of aluminum.

[0023] The extrusion device 1 and the fixed molding device 2 are cylindrical, and the cross-sections of the extrusion device 1 and the fixed molding device 2 are circular ...

Embodiment 2

[0033] combined with figure 1 , a lightweight and efficient polarizing film bending production mold, including extrusion device 1, fixed molding device 2, cylinder 3, the extrusion device 1 is provided with an arc-shaped convex extrusion device working surface 4, the fixed The molding device 2 is provided with a groove that matches the working surface 4 of the extrusion device; the working surface 4 of the extrusion device and the working surface 5 of the fixed molding device are provided with a ceramic layer 6; the extrusion device 1 and The cylinder 3 is fixedly connected, and the cylinder 3 provides power for the extruding device 1 and presses against the fixed forming device 1 to bend the polarizing film 7 into shape.

[0034] The extrusion device 1 and the fixed molding device 2 are made of aluminum.

[0035] The extrusion device 1 and the fixed molding device 2 are cylindrical, and the cross-sections of the extrusion device 1 and the fixed molding device 2 are circular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com