Mounting tool and mounting method for flexible ring-wrapped capacitive sensor

A technology of capacitive sensors and installation tools, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of decreased detection accuracy, sensor damage, and impact on detection accuracy, so as to ensure detection accuracy, avoid overvoltage damage, and ensure detection accuracy. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

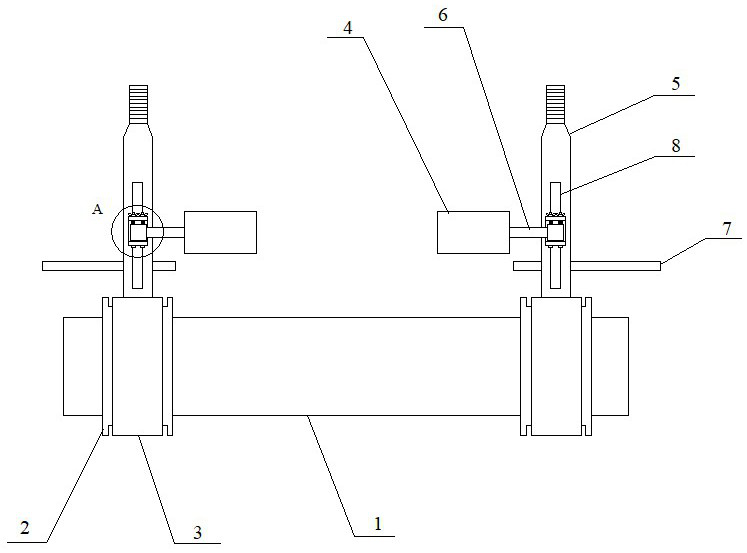

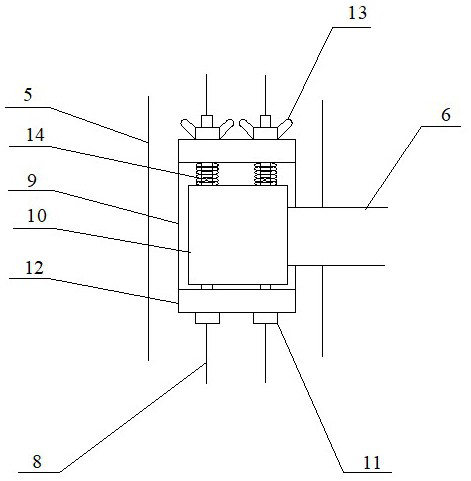

[0038] Such as Figure 1~2 As shown, a flexible ring-wrapped capacitive sensor installation tool is used to install the flexible ring-wrapped capacitive sensor on the cable joint 1, including two fixed rings 2 arranged on both sides of the cable joint, and the fixed rings 2 are rotatably connected The press-fit mechanism; the press-fit mechanism includes a ring sleeve 3, a driver and a press-fit wheel 4, the ring sleeve 3 is set on the outside of the fixed ring 2, and the drive member is arranged on the ring sleeve 3 , the driving member is provided with the pressing wheel 4 for wrapping the flexible ring-wrapped capacitive sensor on the cable joint.

[0039] The outer side of the fixed ring 2 is provided with a groove, and the ring sleeve 3 rotates in the groove.

[0040] The press-fitting wheel 4 is a nylon wheel with good insulation and low hardness, which can avoid abrasion of the flexible capacitive sensor.

[0041] The driving part includes a handle bar 5, a rotating s...

Embodiment 2

[0046] Such as Figure 3~5 As shown, the flexible ring-wrapped capacitive sensor installation tool of the embodiment of the present invention, as a further improvement of the first embodiment, differs from the first embodiment in that:

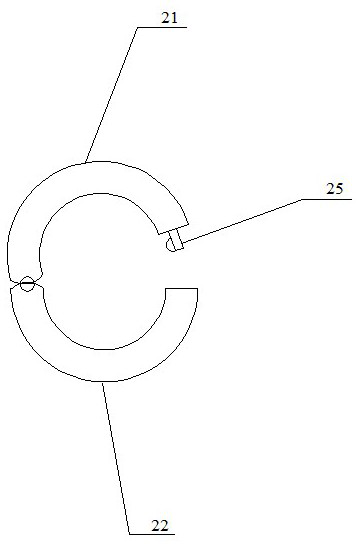

[0047] The fixed ring includes a first fixed ring 21 and a second fixed ring 22 hinged at one end, a first groove 23 is provided on the bottom surface of the other end of the first fixed ring 21, and a pin shaft 24 is arranged in the first groove 23, The lock shaft 24 is connected with a block 25, the upper end of the block 25 is provided with a torsion spring 26, and the torsion spring 26 is sleeved on the pin shaft 24, and the other end of the second fixed ring 22 is provided with a second top surface. Two grooves 27, the second groove 27 is provided with a card slot 28, and the card block 25 is matched with the card slot 27.

[0048] The collar includes a first collar 31 and a second collar 32 hinged at one end, the other end of the first ...

Embodiment 3

[0052] Such as Figure 6~7 As shown, the flexible ring-wrapped capacitive sensor installation tool of the embodiment of the present invention, as a further improvement of the second embodiment, differs from the second embodiment in that:

[0053] The first connecting rod 52 is arranged on the right side of the first handle rod 51, and the end of the first connecting rod 52 is provided with a ferrule nut 53, and the second connecting rod 55 is arranged on the left side of the second handle rod 54, and the second connecting rod 55 is arranged on the left side of the second connecting rod. Threads are provided at the ends of 55 , and the first connecting rod 52 and the second connecting rod 55 are connected and fixed through the ferrule nut 53 .

[0054] A connecting rod 56 is detachably arranged between the two fixing rings, and a roller 57 is fixedly arranged on the connecting rod 56 .

[0055] The inner sides of the two fixed rings are all provided with blind holes, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com