Injection molding machine workpiece dismounting mechanical grasping hand capable of realizing automatic replacement

A mechanical gripper and automatic replacement technology, which is applied in the field of mechanical grippers for injection molding machines, can solve the problems of cumbersome replacement process, grasping plastic parts, and affecting the processing efficiency of plastic parts, so as to reduce the overall weight, smart operation and grasping Take the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

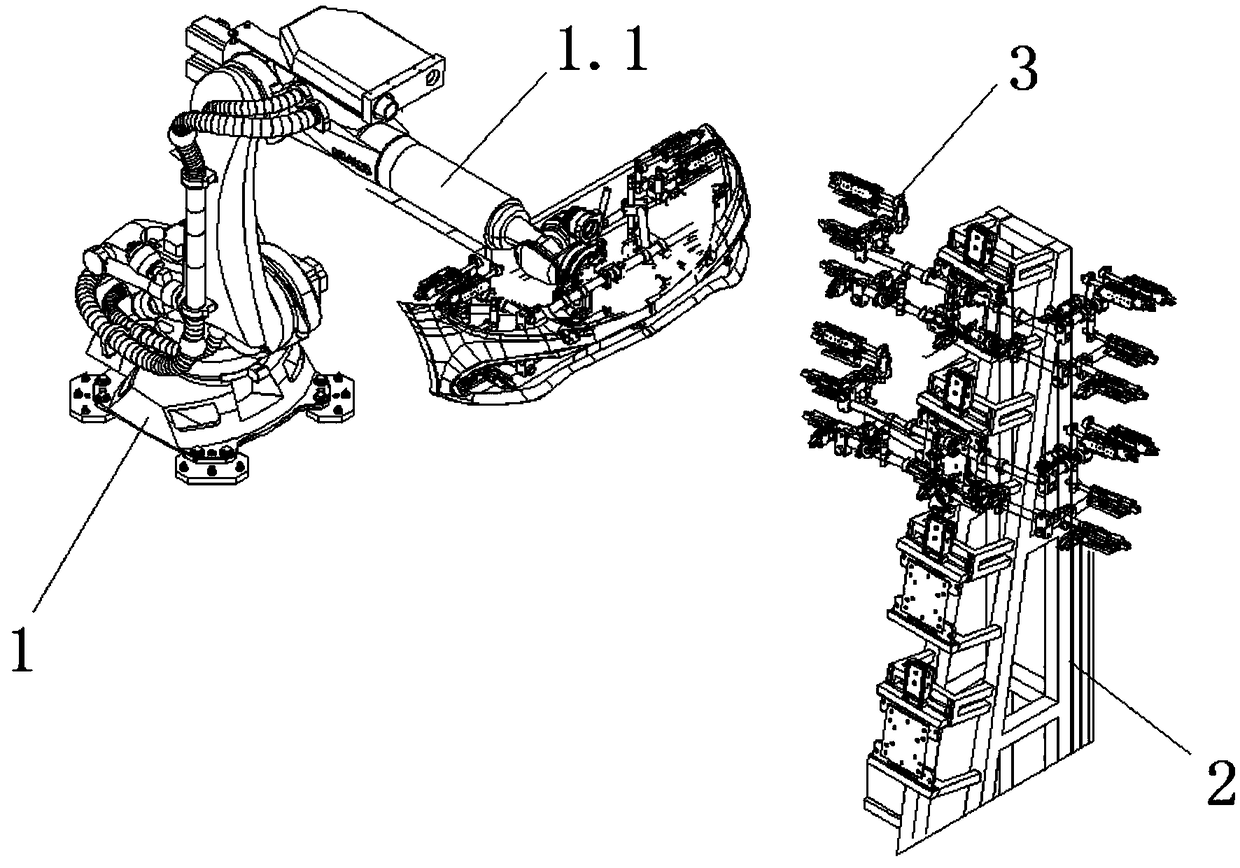

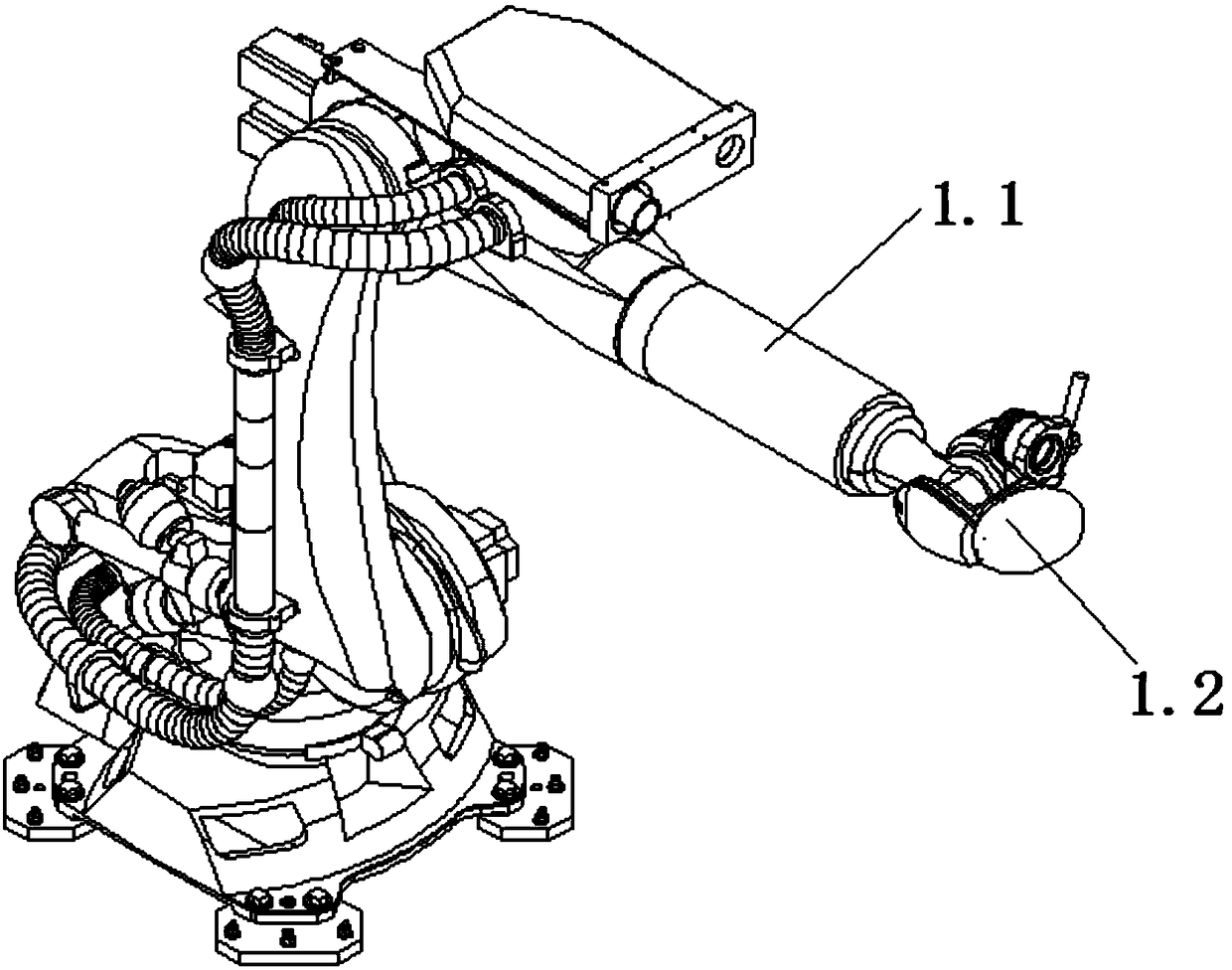

[0016] see Figure 1 to Figure 5 , the present invention relates to an automatically replaceable mechanical gripper for the lower part of an injection molding machine, which includes a robot 1, the bottom of which is fixed on a robot base, a mechanical arm 1.1 is arranged on the side of the robot 1, and the end of the mechanical arm 1.1 Equipped with a male gun changer 1.2.

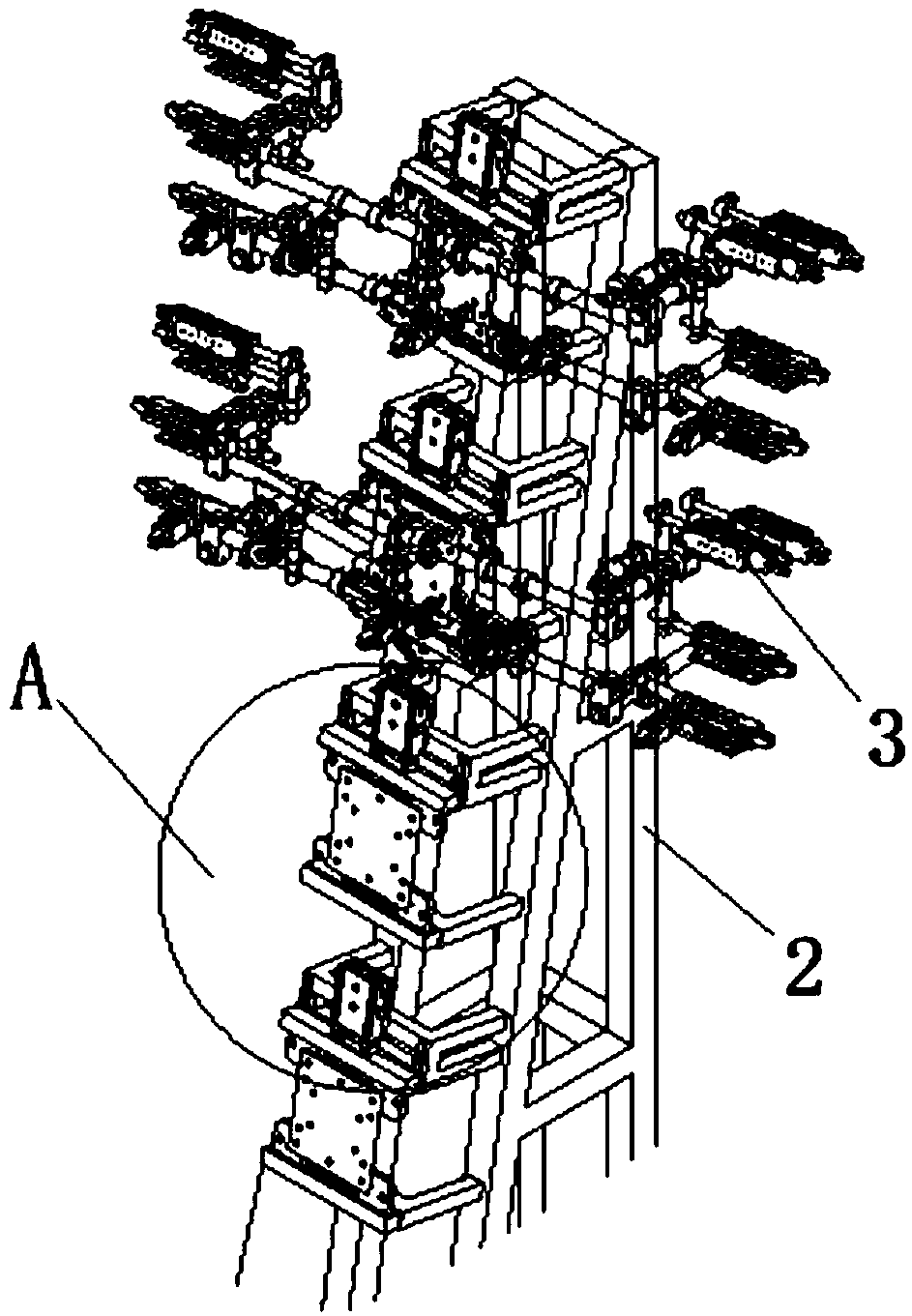

[0017] The right side of the rear end of the robot base is provided with a gripper bracket 2, the bottom of the gripper bracket 2 is fixed on the ground by expansion screws, and the front of the gripper bracket 2 is provided with multiple sets of cylinder clamps 2.1 from top to bottom, two adjacent up and down Cylinder fixtures 2.1 form a group, and the bottom of the upper cylinder and the top of the lower cylinder of each group of cylinder fixtures 2.1 are fixed to the guide rails 2.2 placed horizontally, and there is a mechanical gripper 3 that can be used for replacement between the two guide rails 2.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com