A sealing profile for construction engineering decoration

A technology for construction engineering and profiles, applied in construction, building components, building structures, etc., can solve the problems of coating the joints of profiles, affecting the molding of profiles, and uneven coating of adhesive colloids, and achieve effective splicing. , the effect of uniform coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

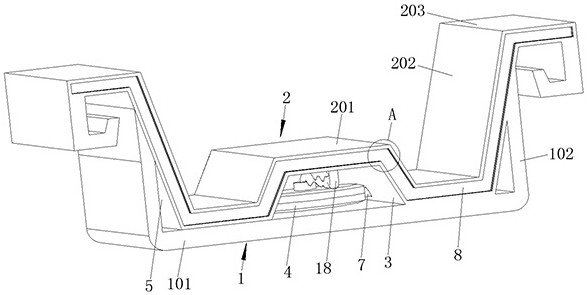

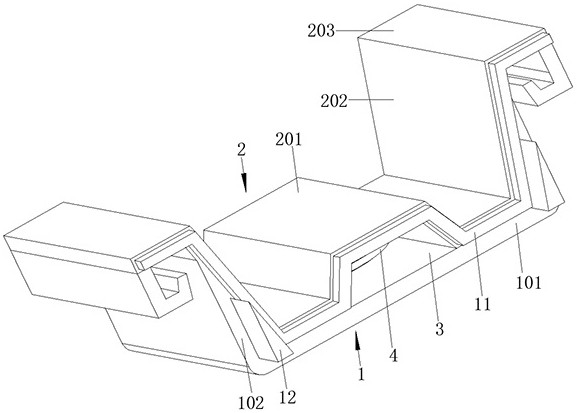

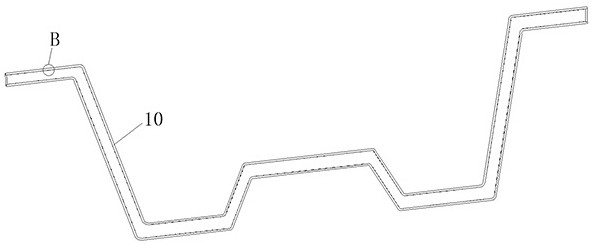

[0039] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 7 , a sealing profile for construction engineering decoration, including a support plate 1, a load-bearing plate 2, the load-bearing plate 2 is fixedly connected to the top of the support plate 1; an installation cavity is provided between the support plate 1 and the load-bearing plate 2 3. There is a sealing rubber tube 4 in the installation cavity 3, a storage cavity 5 is set on both sides of the installation cavity 3, and an air bag 6 is installed in the storage cavity 5, and the air bag 6 is connected to the sealing rubber tube 4 through the air pipe 7; There is a clamping groove 8, and the inner wall of the clamping groove 8 is provided with a serpentine installation groove 9, and the bottom wall of the serpentine installation groove 9 is fixedly connected with a serpentine rubber tube 10, and the top of the sealing rubber tube 4 is connected with the serpentine rubber tube 10 The other...

Embodiment 2

[0041] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 7 , a sealing profile for construction engineering decoration, including a support plate 1, a load-bearing plate 2, the load-bearing plate 2 is fixedly connected to the top of the support plate 1; an installation cavity is provided between the support plate 1 and the load-bearing plate 2 3. There is a sealing rubber tube 4 in the installation cavity 3, a storage cavity 5 is set on both sides of the installation cavity 3, and an air bag 6 is installed in the storage cavity 5, and the air bag 6 is connected to the sealing rubber tube 4 through the air pipe 7; There is a clamping groove 8, and the inner wall of the clamping groove 8 is provided with a serpentine installation groove 9, and the bottom wall of the serpentine installation groove 9 is fixedly connected with a serpentine rubber tube 10, and the top of the sealing rubber tube 4 is connected with the serpentine rubber tube 10 The other...

Embodiment 3

[0044] refer to figure 1 , figure 2 , a sealing profile for construction engineering decoration, which is basically the same as that of Embodiment 1, and furthermore, the top plate 201 is specifically a plate with a groove-shaped cross section, and the groove-shaped cross-section of the top plate 201 is conducive to forming the installation cavity 3, the wing The board 202 is inclined to the top board 201, and the obtuse angle between the wing board 202 and the top board 201 is 100-120 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com