tip turbine engine

A turbine engine and propeller tip technology, which is applied in the direction of engine components, turbine/propulsion device intake, charging system, etc., can solve problems such as aerodynamic performance matching, and achieve the effect of solving dynamic sealing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

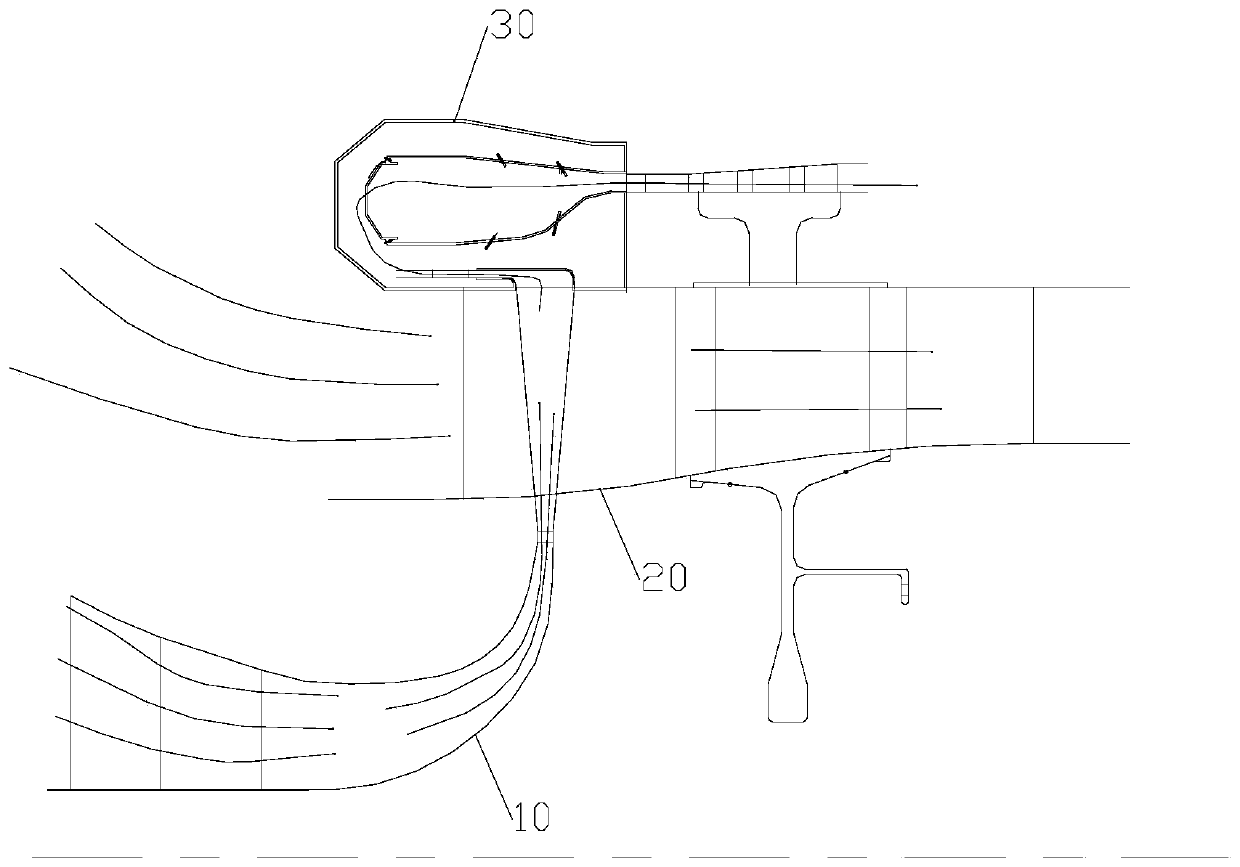

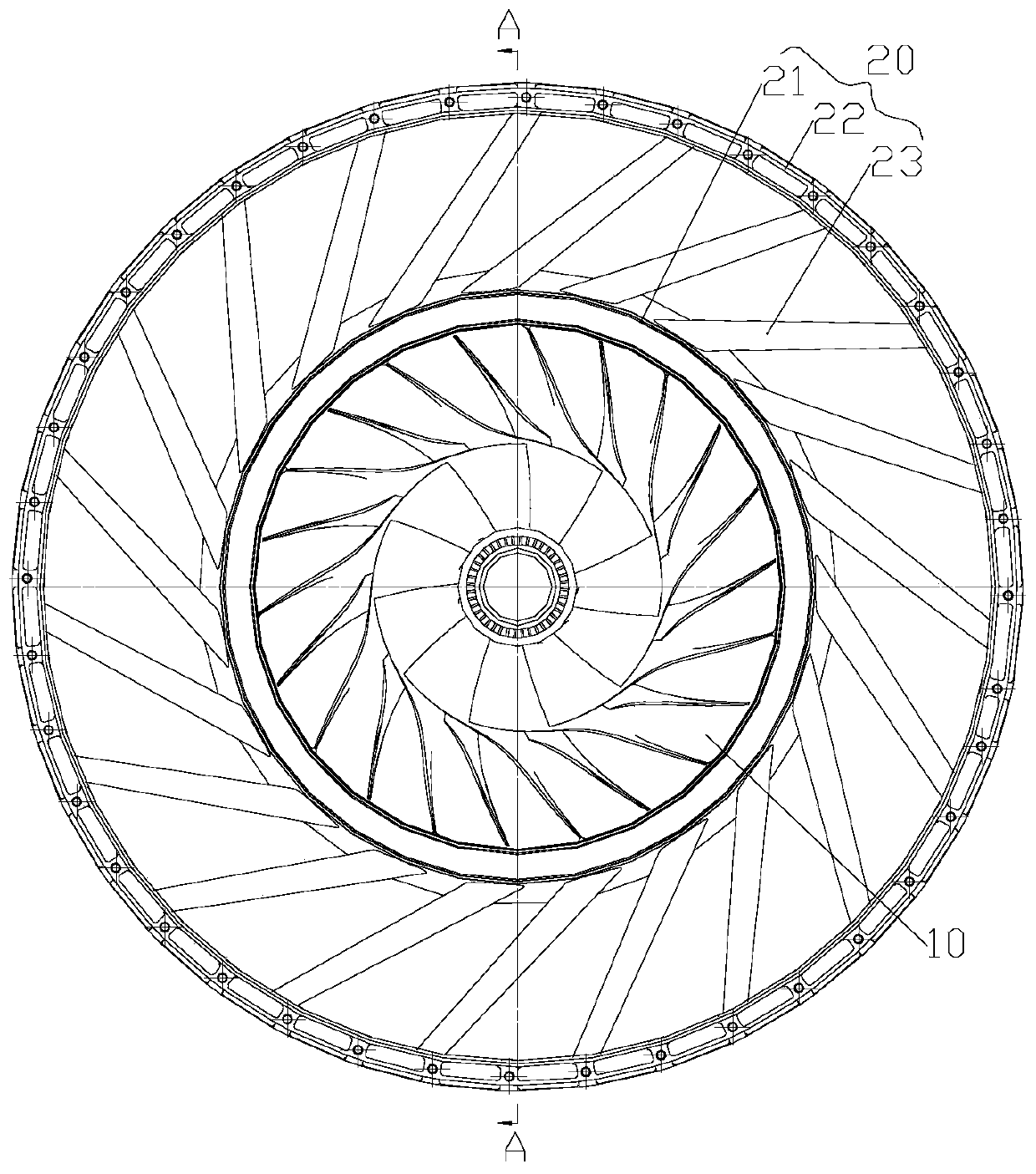

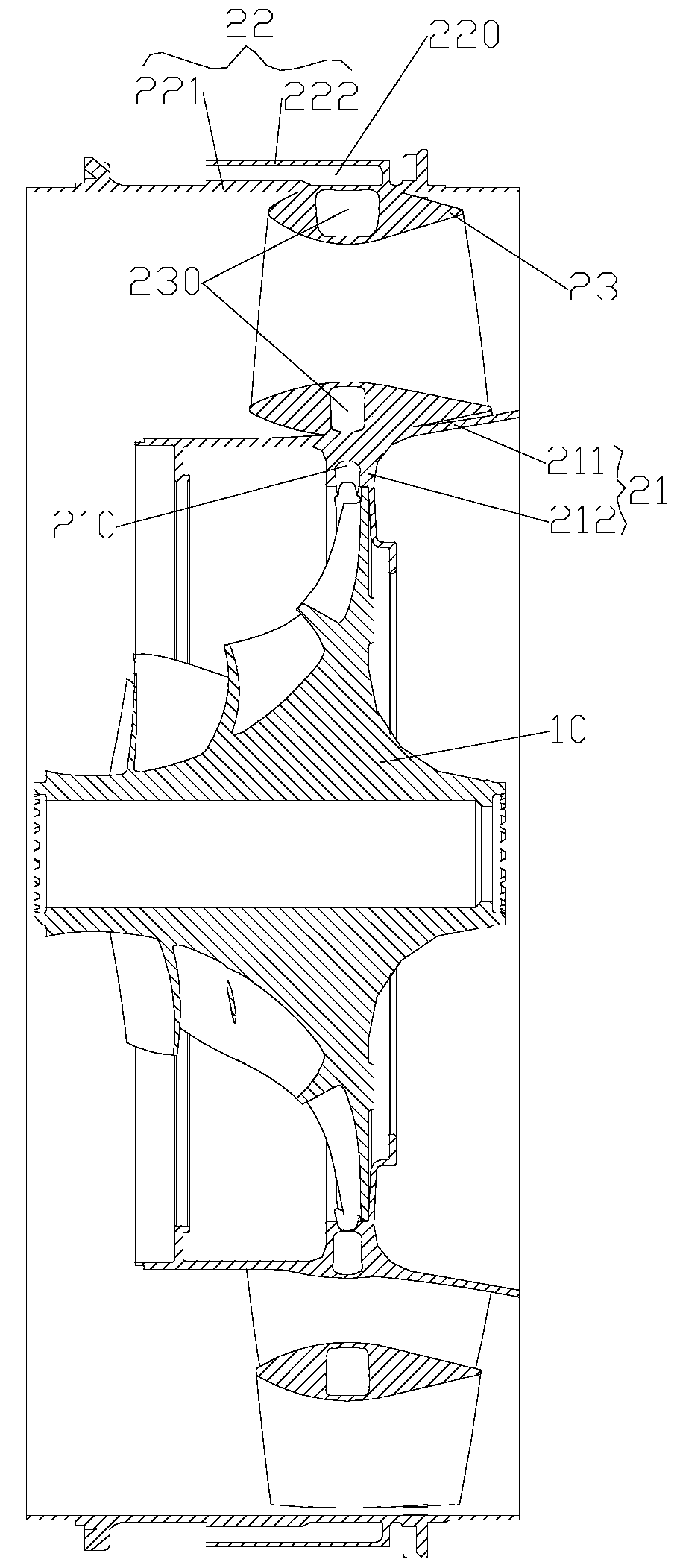

[0027] refer to figure 1 , the preferred embodiment of the present invention provides a blade-tip turbine engine, including: a high-pressure compressor 10 that is rotated, and the high-pressure compressor 10 is used to compress the incoming air along the axial direction and then flow out at high speed along its radial direction. The compressor 10 is covered with a fan stator 20 for diffusing and decelerating the incoming air and then flowing out. The fan stator 20 is ring-shaped and fixedly arranged. The outer duct of the fan stator 20 is provided with a combustion chamber 30 . The air intake end of the fan stator 20 is matched with the exhaust end of the high-pressure compressor 10, so that the high-speed airflow flowing out of the high-pressure co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com