Rolling Bearing Fault Diagnosis Method Based on Conditional Empirical Wavelet Transform

An empirical wavelet, rolling bearing technology, applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., can solve problems such as inappropriate frequency spectrum division, pre-defined modal number, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

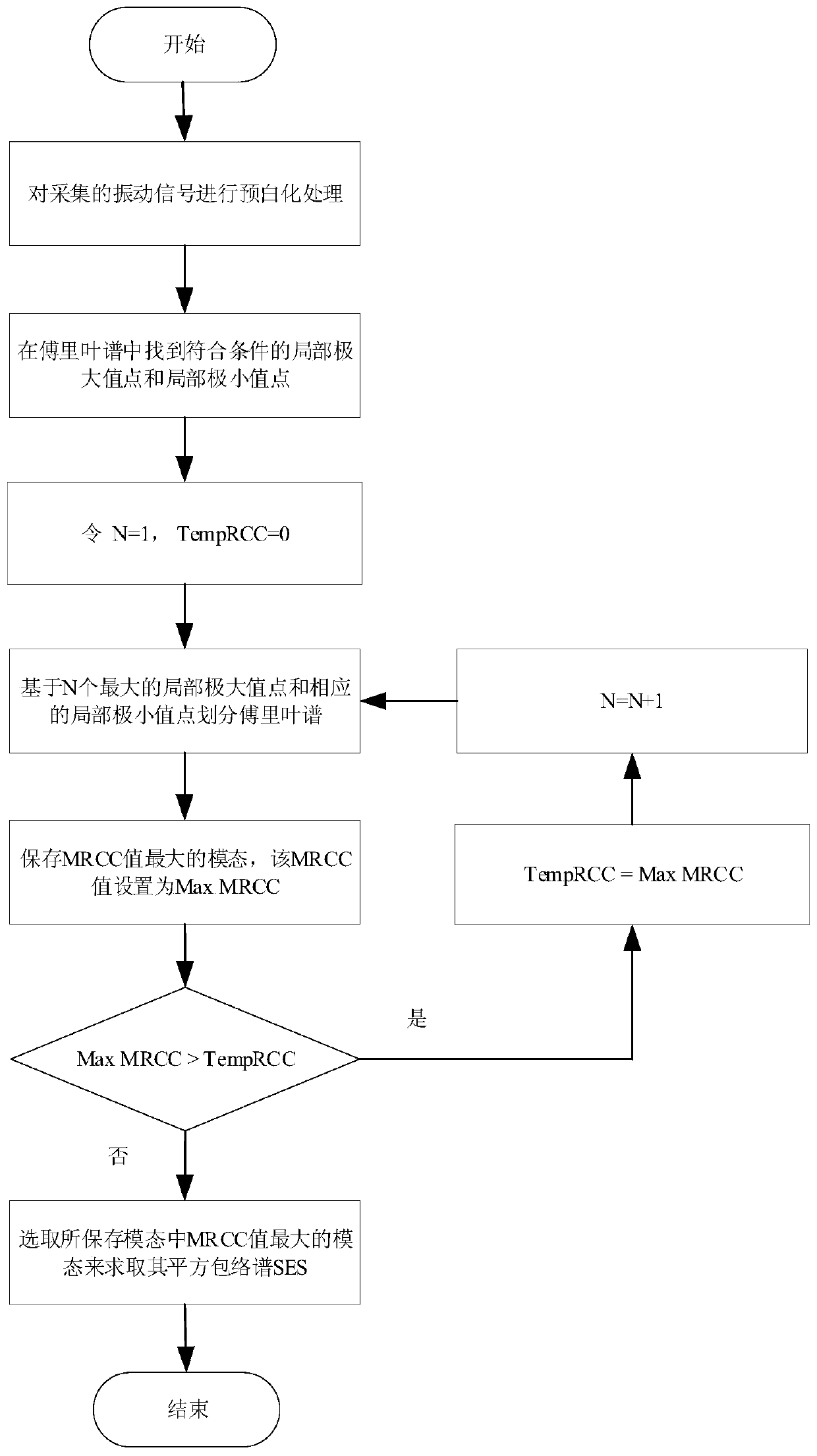

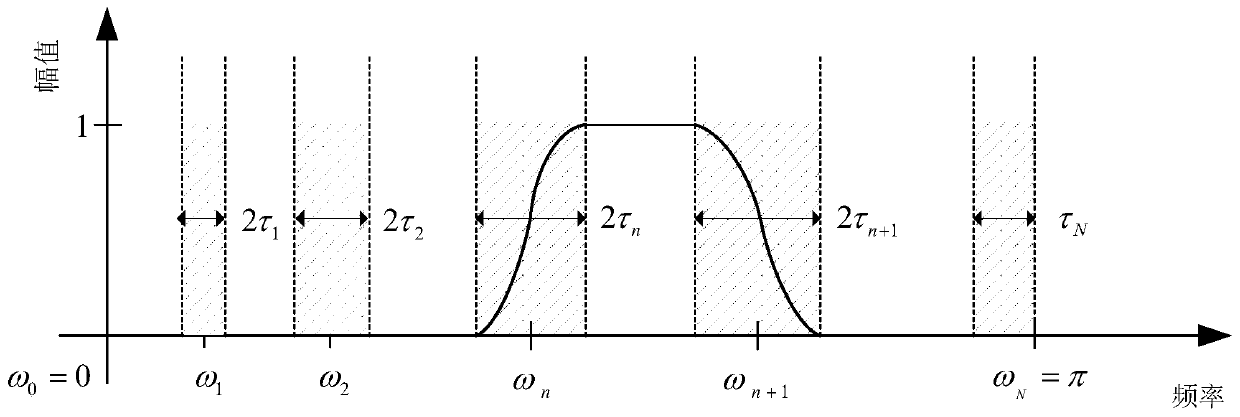

Method used

Image

Examples

Embodiment 1

[0122] Example 1: Mode selection

[0123] In order to demonstrate the advantages of the MRCC index in mode selection, an example is used to compare the signal time domain kurtosis value K t , The frequency band spectrum kurtosis value K used by Fast Kurtogram b , RCC and MRCC performance in modality selection. If these indicators are the largest for a modal, it indicates that these indicators select the modal. The time-domain diagram of an inner ring fault vibration signal decomposed into three modes by EWT is as follows: Figure 3a-Figure 3c As shown, the square envelope spectrum decomposed into three modes by EWT is as Figure 4a-Figure 4c shown. It can be seen from the figure that although from the time domain form, the impact of mode 1 and mode 2 is more, but the characteristic frequency f of the inner ring fault is not found in the square envelope spectrum i . This shows that the shocks in Mode 1 and Mode 2 are not caused by inner race faults. In contrast, the char...

Embodiment 2

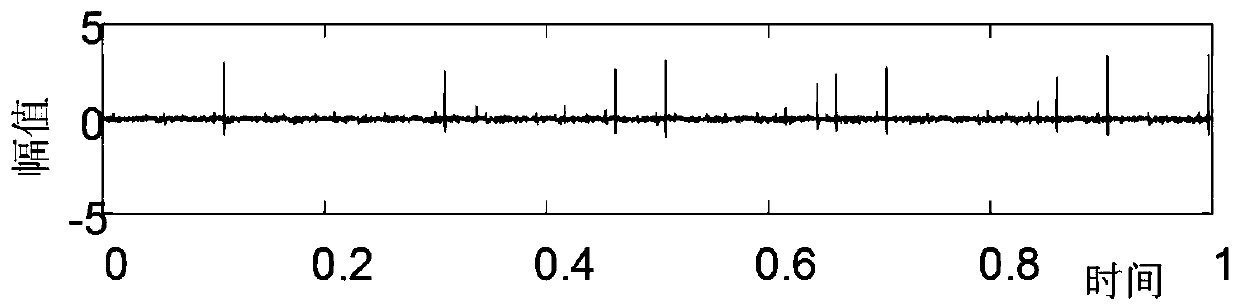

[0127] Embodiment 2: Rolling bearing fault diagnosis

[0128] In order to demonstrate the effect of the present invention "Rolling Bearing Fault Diagnosis Based on Conditional Empirical Wavelet and Improved Cycle Composition Ratio", this example takes the disclosed bearing outer ring fault data as an example, and uses the present invention, EWT and Fast kurtogram to process the data respectively. In order to make the comparison fair, the pre-whitening processing is used as the pre-processing means of the three methods, and the pre-whitening processing method used in Fast Kurtogram is used. In addition, the EWT modal number remains the same as that of the present invention, which is automatically determined by the MRCC. The bearing data adopts the high-speed bearing outer ring fault data provided by Acoustics and VibrationDatabase, and the bearing vibration data is collected by Gareth Forbes of Curtin University. The acquisition frequency of the vibration signal is 51.2kHz, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com