light guide plate

A technology of light guide plate and substrate, applied in the field of light guide plate, which can solve the problems of vignetting, difference between the brightness and darkness of the picture, and the dark part of the light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of a preferred embodiment with reference to the accompanying drawings. The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only referring to the directions of the drawings. Accordingly, the directional terms are used to illustrate and not to limit the invention.

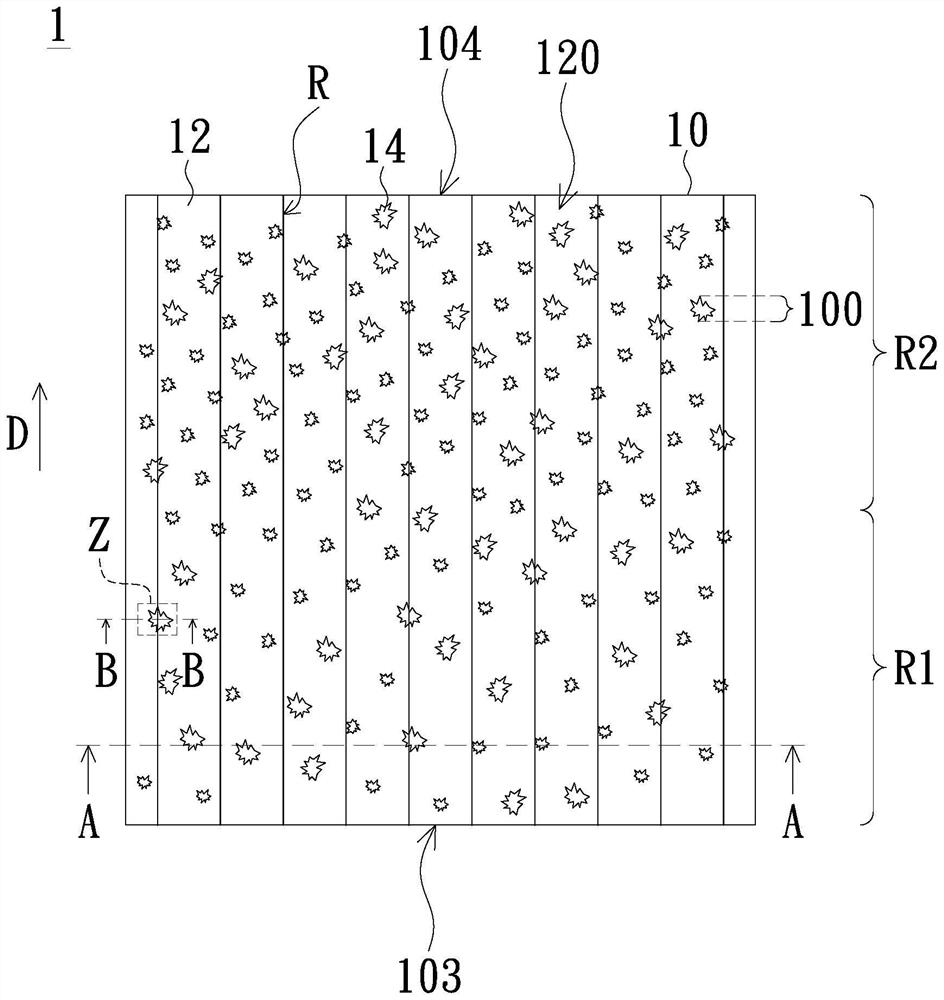

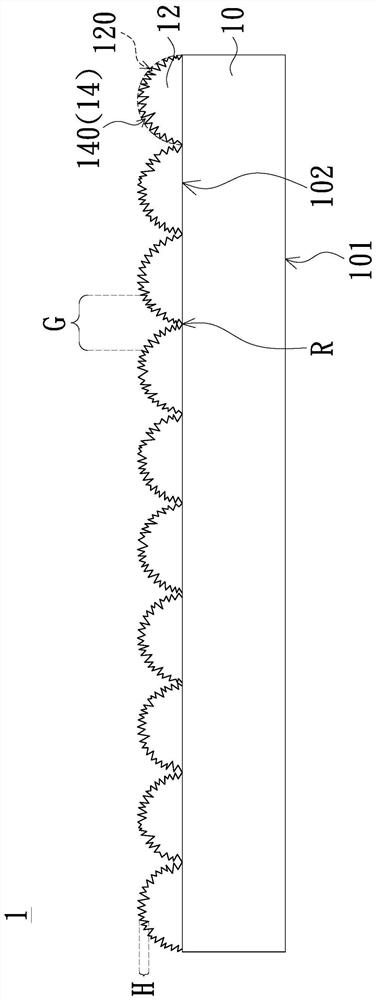

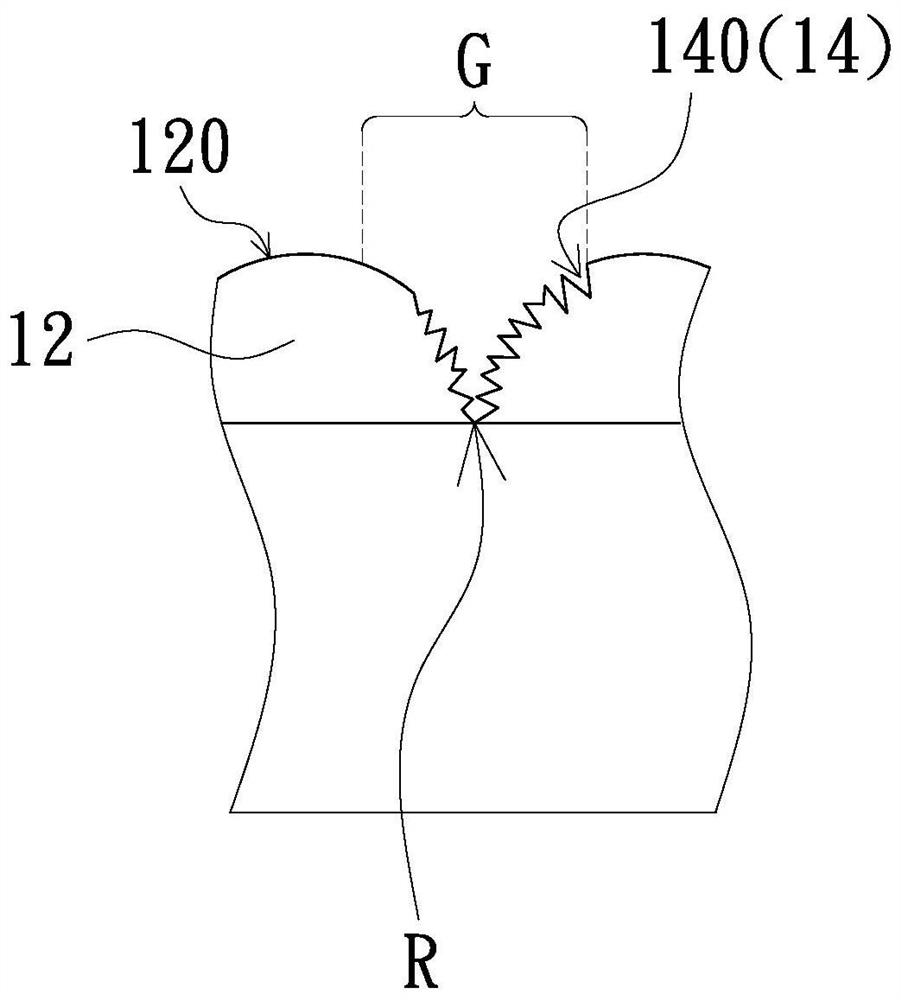

[0016] Please refer to figure 1 and figure 2 , figure 1 It is a schematic top view of a light guide plate according to an embodiment of the present invention. figure 2 for along figure 1 Schematic cross-sectional view of line AA shown. like figure 1 and figure 2 As shown, the light guide plate 1 of this example includes a substrate 10 , a plurality of lens microstructures 12 and a plurality of dot patterns 14 . The substrate 10 has a light emitting surface 101 , a bottom surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com