A laser light path of dissipating spots, a two-color laser light source, and a three-color laser light source

A laser light source, speckle dissipation technology, applied in optics, optical components, instruments, etc., can solve problems such as speckle effect, and achieve the effect of improving the degree of uniform distribution and improving the efficiency of light processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

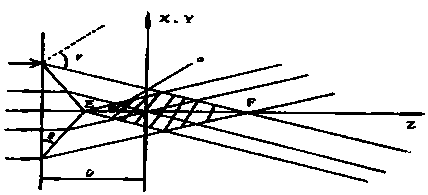

[0047] Embodiment 1 of the present invention provides a laser speckle dissipated optical path, such as Figure 4 As shown, including lasers 1, there can be one or more groups that emit laser light. The lasers can be blue lasers, red lasers or green lasers, and the specific color is not specifically limited.

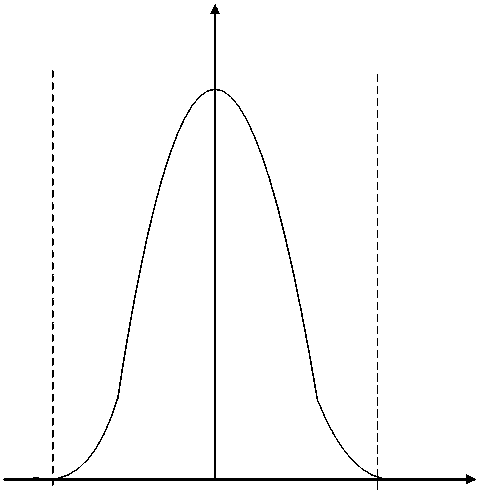

[0048] In the speckle-dissipating light path, a first conical mirror 3 , a diffusion sheet 4 , and a second conical mirror 5 are sequentially arranged along the laser exiting light path. Among them, the first conical mirror 3 is used to homogenize and shape the laser beam, the diffuser 4 is used to diffuse the laser beam homogenized and shaped by the first conical mirror, and the second conical mirror is used to The laser beam is collected and homogenized again.

[0049] Specifically, since the diameter of the laser spot emitted by the laser is about 60 mm, in order to improve the transmission efficiency and shaping efficiency of the laser beam, a beam shrinking componen...

Embodiment 2

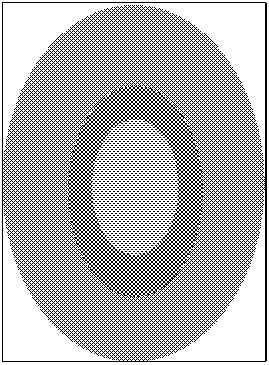

[0063] Embodiment 2 of the present invention provides a two-color laser light source, and applies the optical path of laser speckle dissipation described in Embodiment 1 to a two-color laser light source architecture.

[0064] Specifically, such as Figure 7 As shown, the two-color laser light source includes a blue laser 11 and a red laser 12, which respectively emit blue laser and red laser. The blue laser and the red laser can be divided into one or more groups, and the two can be arranged side by side or vertically. The setting will be selected in consideration of the volume of combined light path and the complexity of the heat dissipation structure during specific implementation; and the fluorescent wheel 3 is set in the blue laser exit light path, including the fluorescent area (not shown in the figure) and the transmission area (not shown in the figure), the fluorescent area is provided with green fluorescent powder for being excited by blue laser light to generate gree...

Embodiment 3

[0083] The difference between Embodiment 3 of the present invention and Embodiment 2 is that the fluorescent wheel 3 is a reflective fluorescent wheel, such as Figure 8As shown, the fluorescent light generated by the excitation of the reflective fluorescent wheel is emitted toward the direction opposite to the incident direction of the blue laser light through the reflection of the aluminum substrate, and the light-combining component 4 is placed in front of the fluorescent wheel 3 .

[0084] In order to collimate the transmitted blue laser light and the reflected fluorescent light, collimating lens groups 28 need to be arranged on the front and back of the fluorescent wheel 3 . Wherein the blue laser will also pass through the relay circuit after passing through the collimating lens group 28 on the back side of the fluorescent wheel, including parts such as a relay lens and a plane reflector, such as Figure 9 The optical component 25 shown returns to the light combining com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com