A method for online tracking and smooth switching of control modes of hydraulic material testing machine

A material testing machine, control mode technology, applied in the field of online tracking, can solve the problem of difficult to achieve smooth switching, and achieve the effect of smooth switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

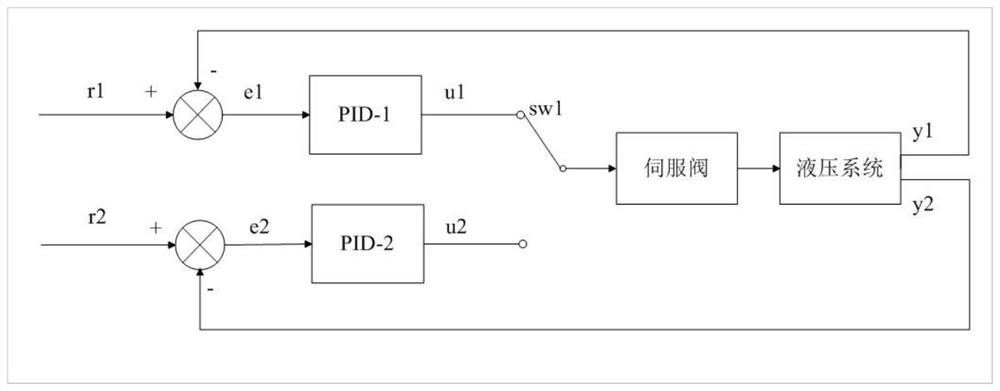

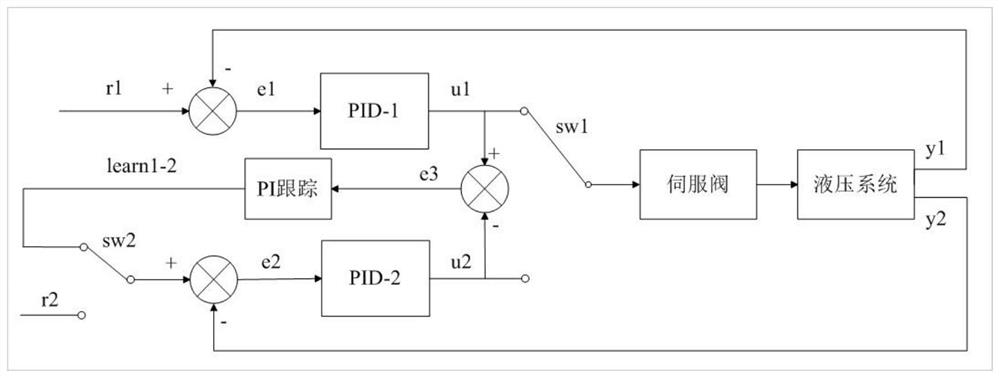

[0021] The control methods of the material testing machine all adopt PID control, but the system characteristics of the displacement, load and strain control modes are different, and the PID parameters of each control mode are also different. Without loss of generality, any two control modes are used to illustrate the smooth switching process between control modes, figure 1 The general switching process from control channel 1 to control channel 2 is shown.

[0022] In the figure, the control mode is in the closed-loop state of channel 1, r1 is the input command signal of channel 1, y1 is the output signal of channel 1, and is used as a feedback signal to the input terminal, e1 is the error signal of channel 1, and its value is r1 and y1 The difference, u1 is the output signal of the error signal e1 after passing through the PID-1 controller, and is the driving voltage of the control channel 1.

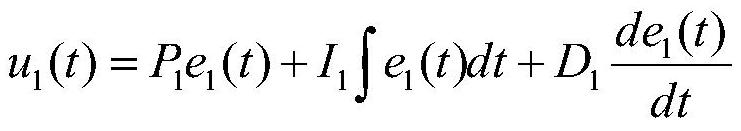

[0023]

[0024] In the formula, P 1 is the scaling factor of channel 1, I 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com